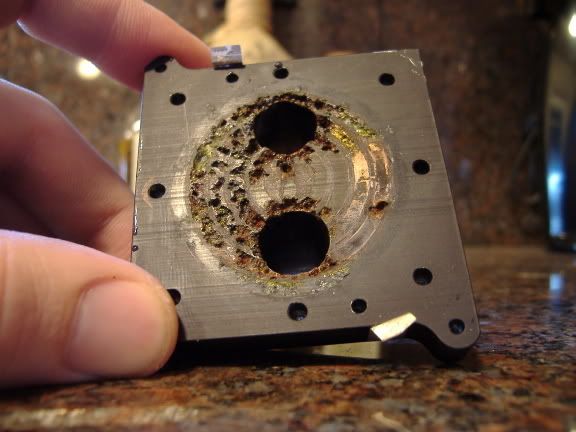

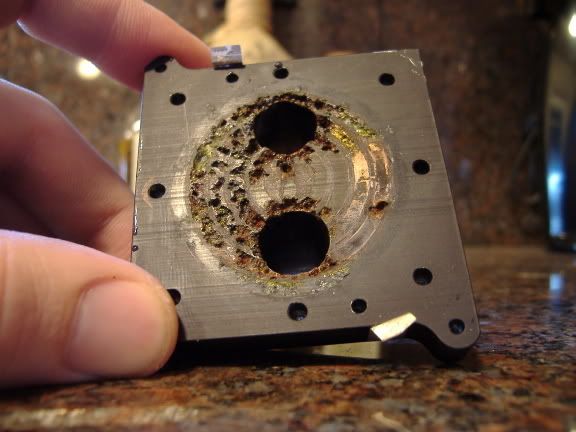

this week i upgraded my PC some and in the process i decided to run air cooling for the time being while i tryed to figure out what was contaminateing my water system... well i found it

we know better than to mix alu and copper, but anodizeing should have rendered this a null point, regardless considering there was alu oxide caked onto my cpu block, (loop went pump>rad>cpu>nb>gpu>filler>pump ) means my rad has got to be filled with crap... and i had to SCRAPE it off (i used a plastic fork so i didnt mar the inside of the tdx) and seeing as how i cant just rip open the rad to scarpe at it what should i do???

there was nothing in the system but distilled water ( i had some dylite in the system at one point but it was befor i had this block and has been flush about 4 times sence then)

here the catch i had to void the warrenty to find this damage, do you guys think i have a leg to stand on here? im not so worried about the gpu block as i am the rad but regardless the gpu will have to be replace, the question is should the rad be replaced as well?

regardless im going to fire off a e-mail to the guys at DD and see what they can do about my gpu block. the copper base is just fine it all came off the top part.

we know better than to mix alu and copper, but anodizeing should have rendered this a null point, regardless considering there was alu oxide caked onto my cpu block, (loop went pump>rad>cpu>nb>gpu>filler>pump ) means my rad has got to be filled with crap... and i had to SCRAPE it off (i used a plastic fork so i didnt mar the inside of the tdx) and seeing as how i cant just rip open the rad to scarpe at it what should i do???

there was nothing in the system but distilled water ( i had some dylite in the system at one point but it was befor i had this block and has been flush about 4 times sence then)

here the catch i had to void the warrenty to find this damage, do you guys think i have a leg to stand on here? im not so worried about the gpu block as i am the rad but regardless the gpu will have to be replace, the question is should the rad be replaced as well?

regardless im going to fire off a e-mail to the guys at DD and see what they can do about my gpu block. the copper base is just fine it all came off the top part.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)