My earlier version was made out of plastic. Much simpler as well.

http://www.hardforum.com/showthread.php?t=1123090&highlight=crossflow

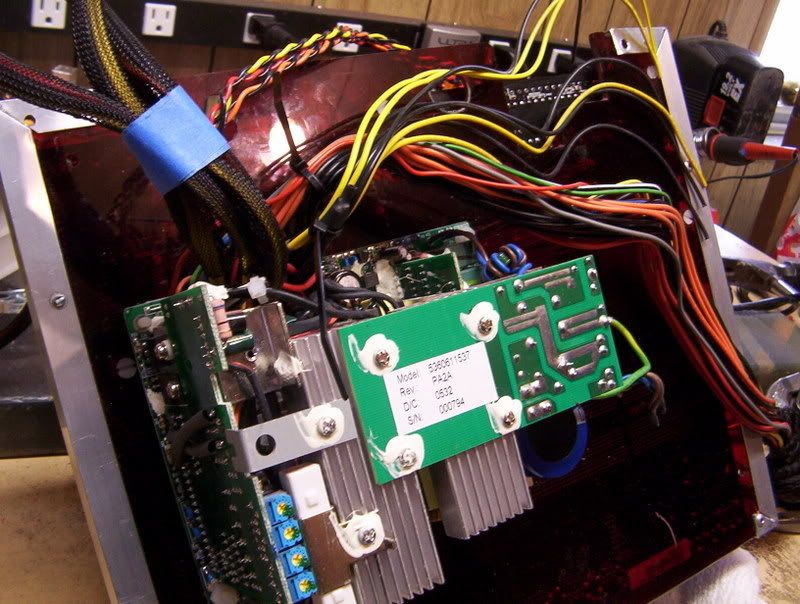

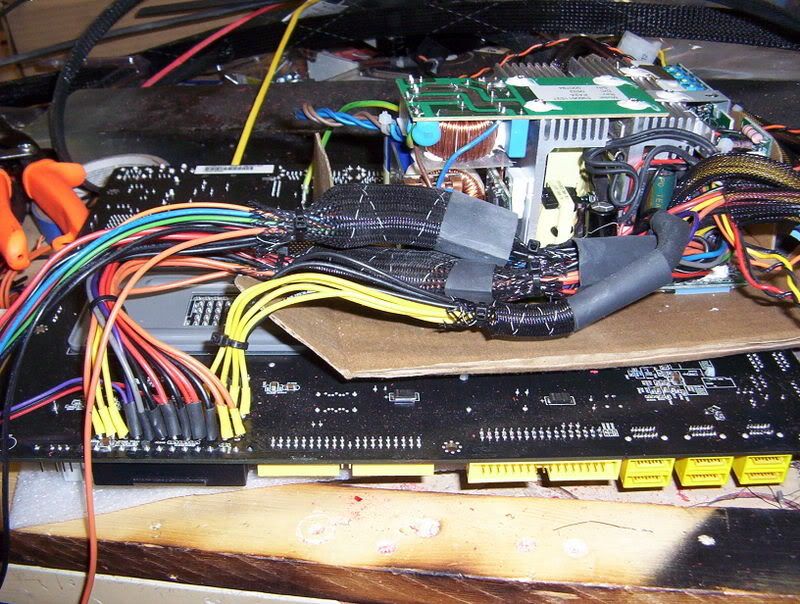

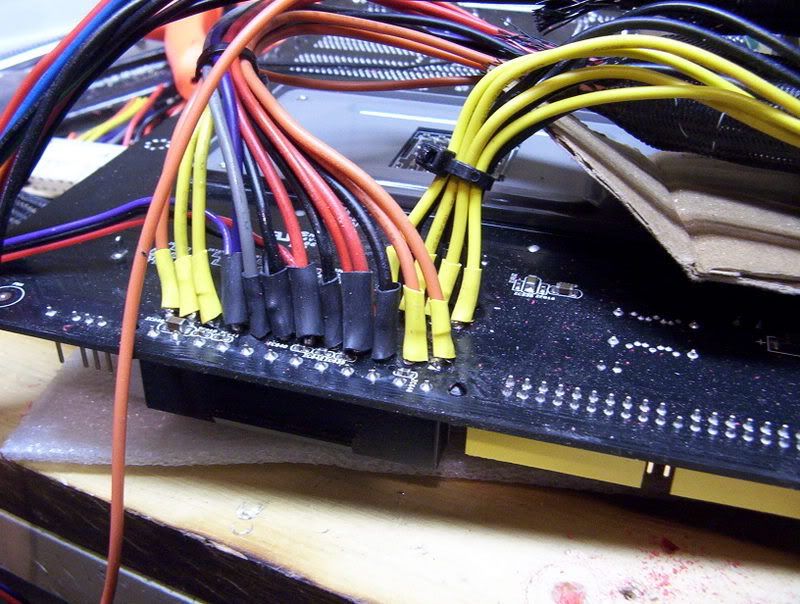

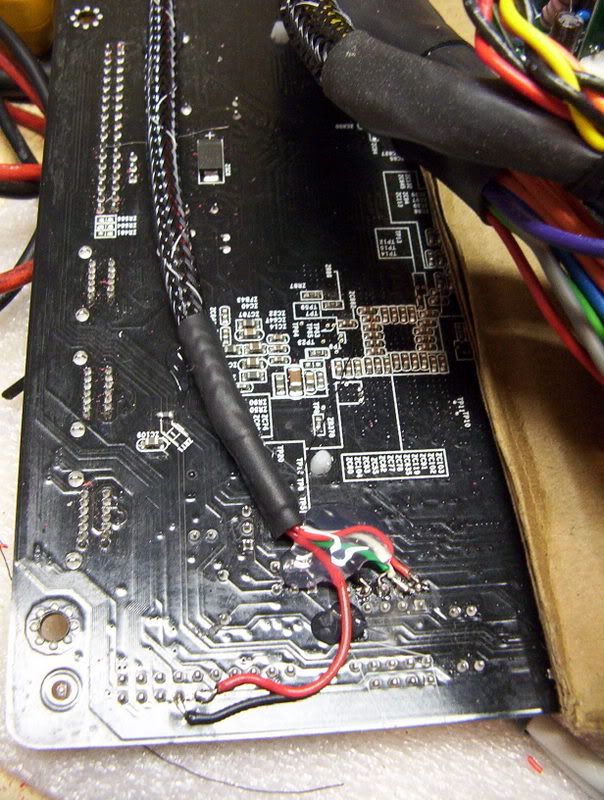

I like to mount the PS under the mobo so it frees up the top and definitely eliminates clutter which aids airflow a bunch.

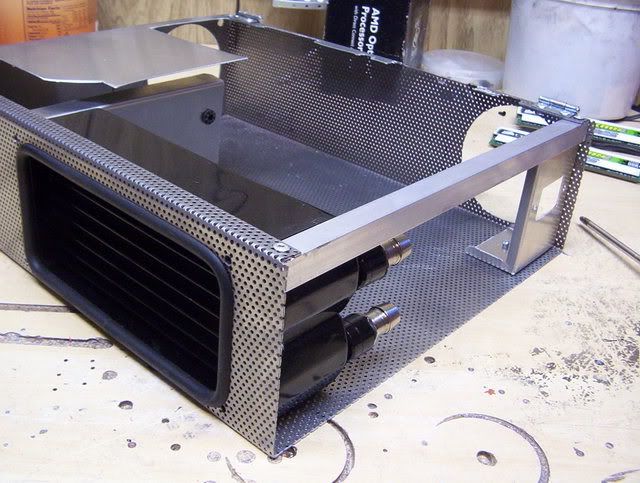

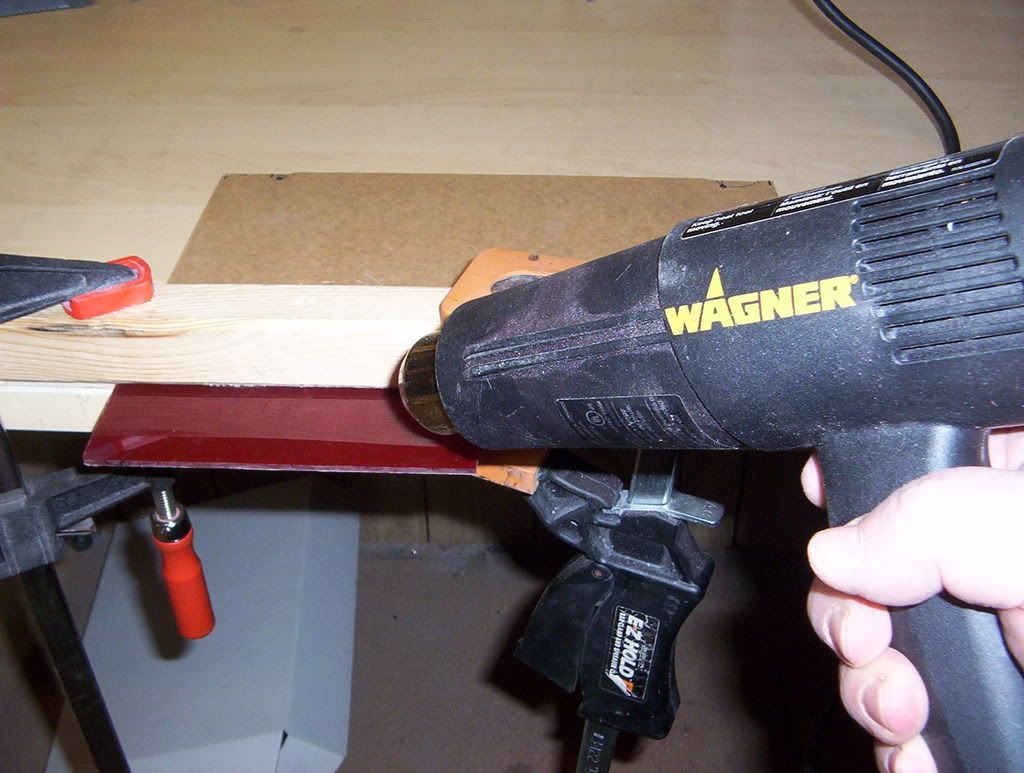

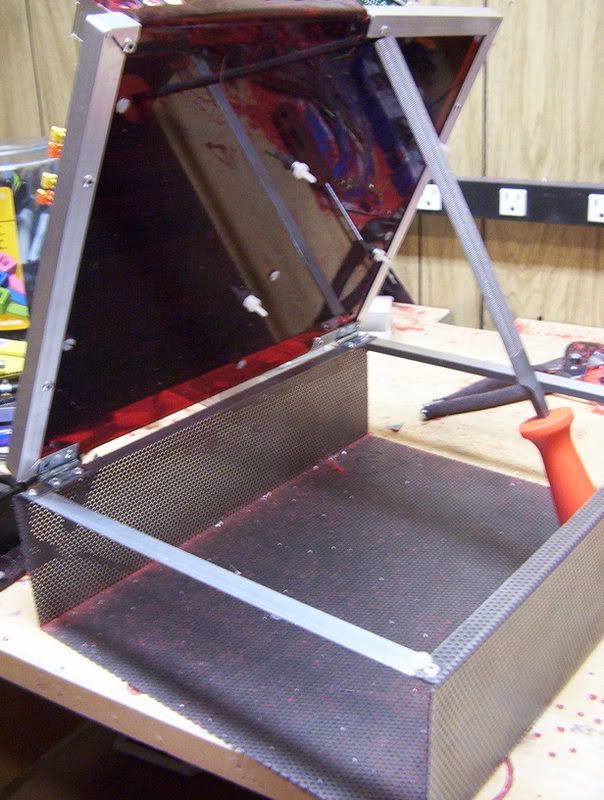

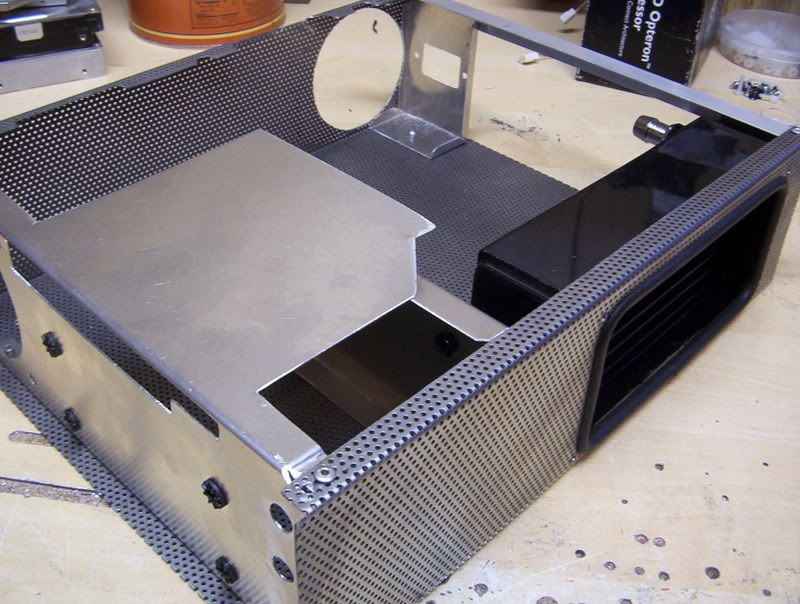

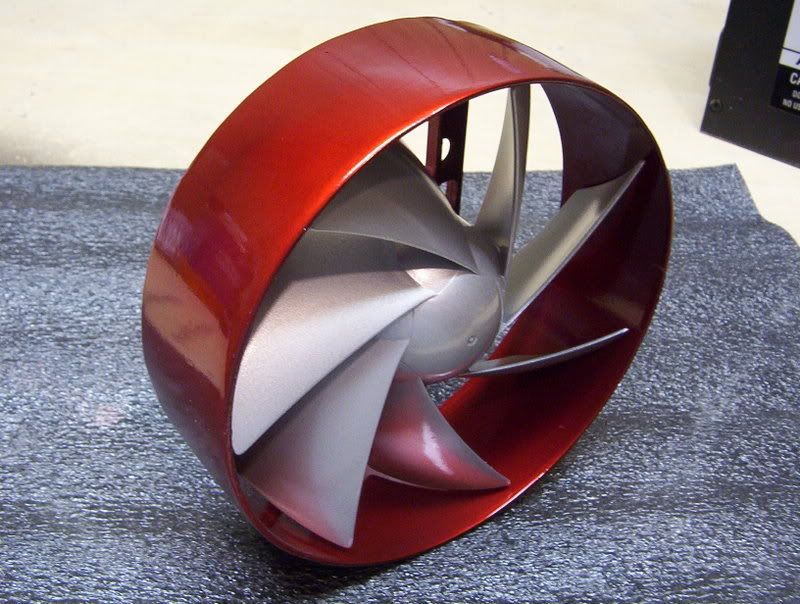

For this version I am going to use perforated steel and Plastic. I built this a month ago for PDXLAN and was putting in 20+ hour days so I couldn't post it on multiple forums. Now its done I thought I would post the picts here because there are some cool ideas.

Basically my thought is to use a full size ATX mobo in a case smaller than a Qpack. I posted the original in the SFF forum but because I dont use a mATX mobo they say I cant be part of their group

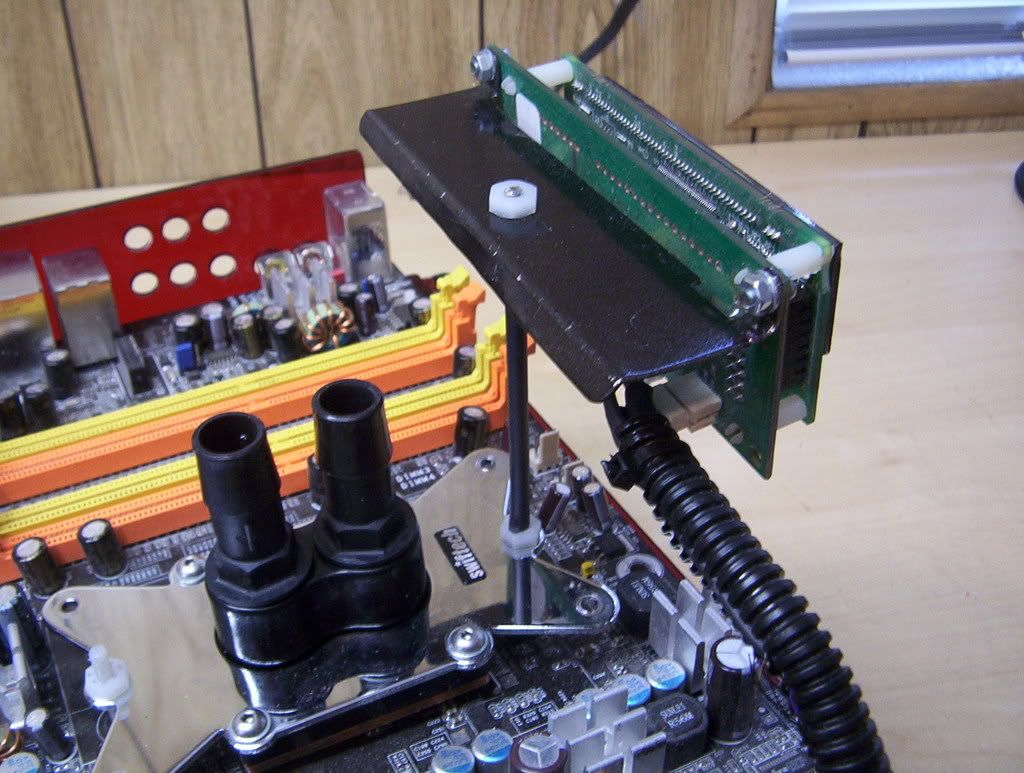

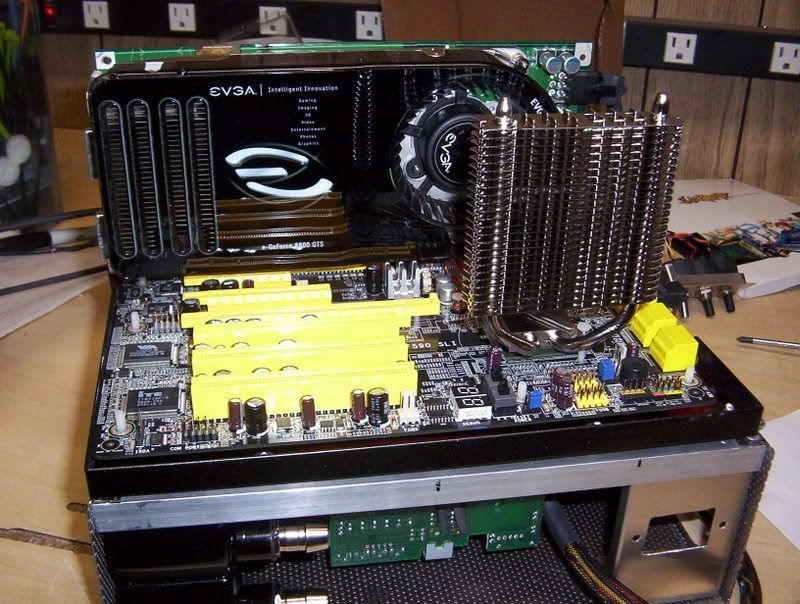

For this version I will be Using a DFI LP 590 mobo, 8800GTS, PC Power&Cooling 510 (thanks

DELL_DUDE_B120 ) and Dangerden/Swiftech water cooling.

Here is a pict of one of my first comps. A Qpack showing just how cluttered the insides are

For those interested in Dimentions this comp is 10 1/2" wide X 12 3/4" deep X 8 3/4" tall (and can house a pair of 8800GTS EASY)

http://www.hardforum.com/showthread.php?t=1123090&highlight=crossflow

I like to mount the PS under the mobo so it frees up the top and definitely eliminates clutter which aids airflow a bunch.

For this version I am going to use perforated steel and Plastic. I built this a month ago for PDXLAN and was putting in 20+ hour days so I couldn't post it on multiple forums. Now its done I thought I would post the picts here because there are some cool ideas.

Basically my thought is to use a full size ATX mobo in a case smaller than a Qpack. I posted the original in the SFF forum but because I dont use a mATX mobo they say I cant be part of their group

For this version I will be Using a DFI LP 590 mobo, 8800GTS, PC Power&Cooling 510 (thanks

DELL_DUDE_B120 ) and Dangerden/Swiftech water cooling.

Here is a pict of one of my first comps. A Qpack showing just how cluttered the insides are

For those interested in Dimentions this comp is 10 1/2" wide X 12 3/4" deep X 8 3/4" tall (and can house a pair of 8800GTS EASY)

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)