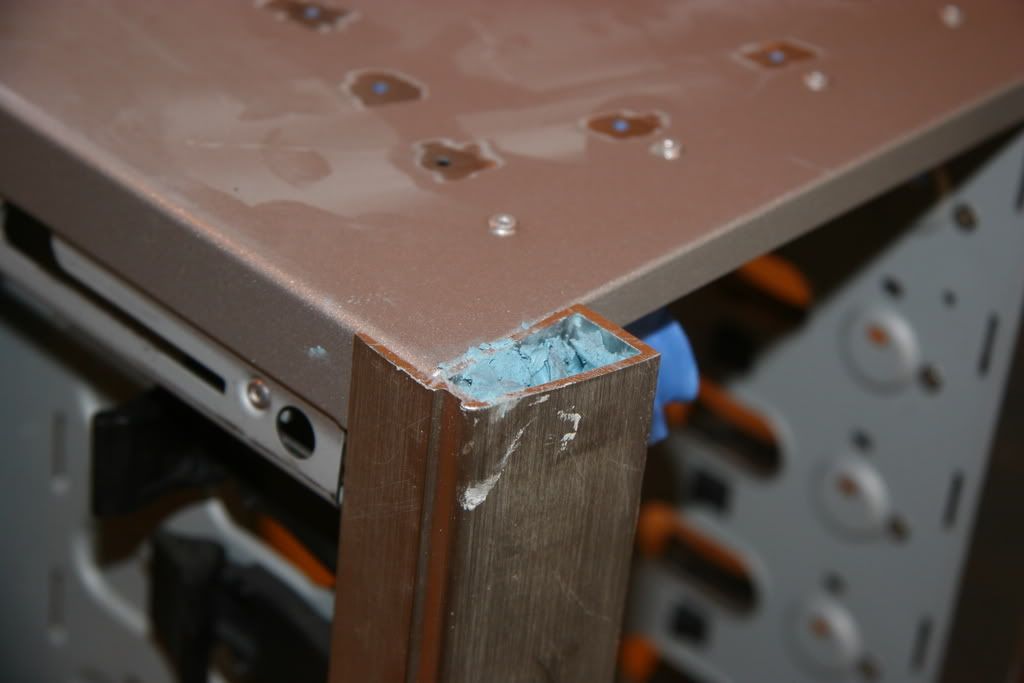

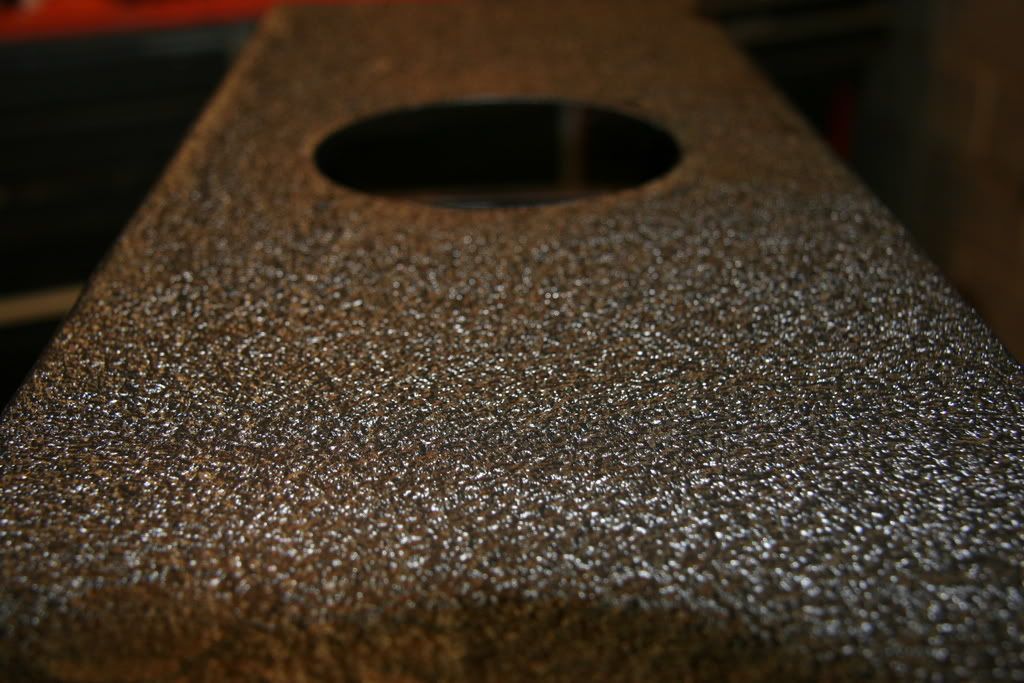

Here's my first case modding attempt. Wish me luck! I'm kinda playing it as I go, but I had a few things in mind, WC for one and the placement of equipment, but I'm sure some things will come to me as I get in the later stages.

It will also be painted.

I'm going to number every picture so it's easy to reference if you have a suggestion or comment.

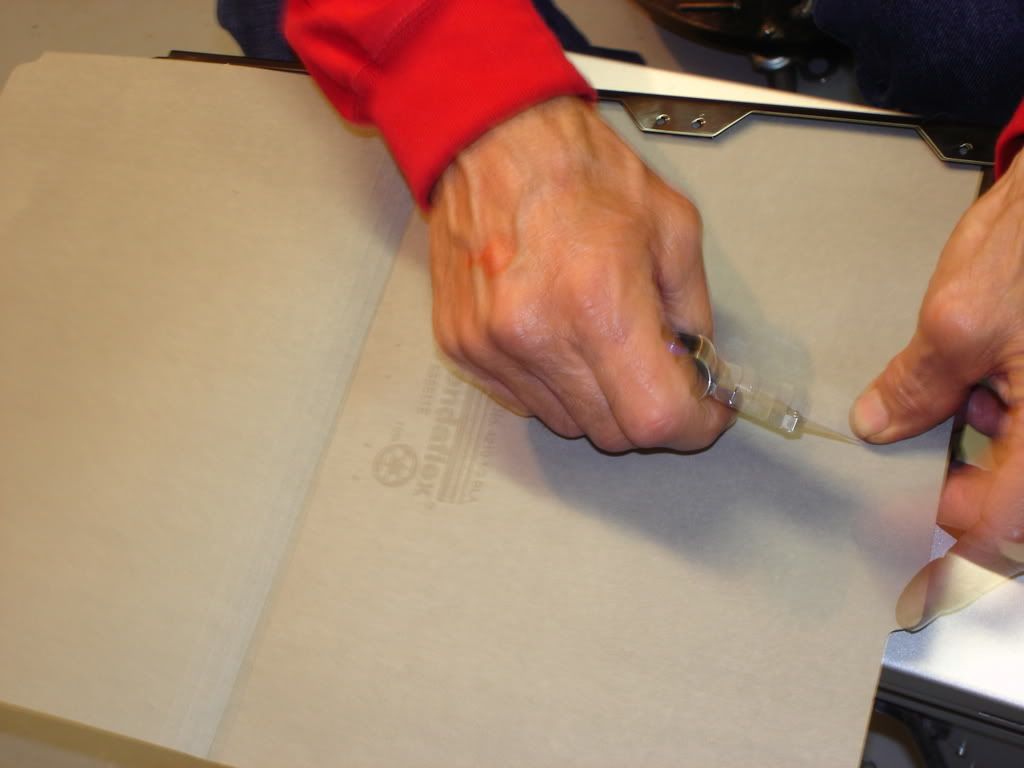

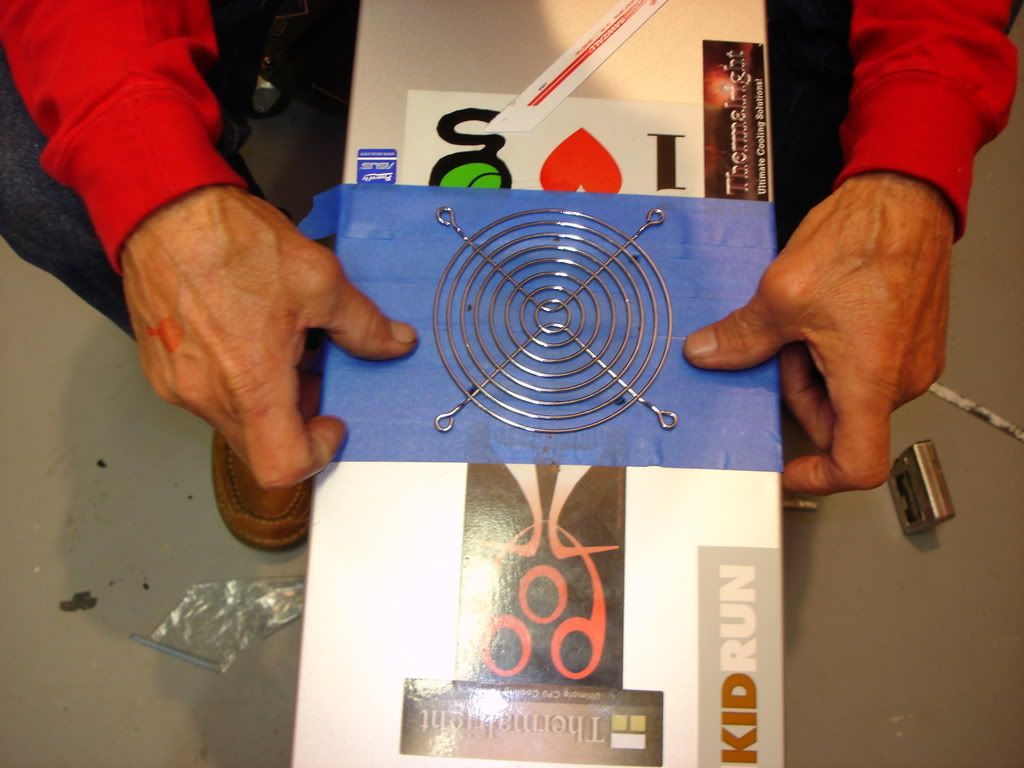

And btw, I don't have 3 arms, my dad is doing some of the work so I can take pictures of the process, but I am doing most of it. I just wanted to get pictures of the actual n00bie techniques I used for this project.

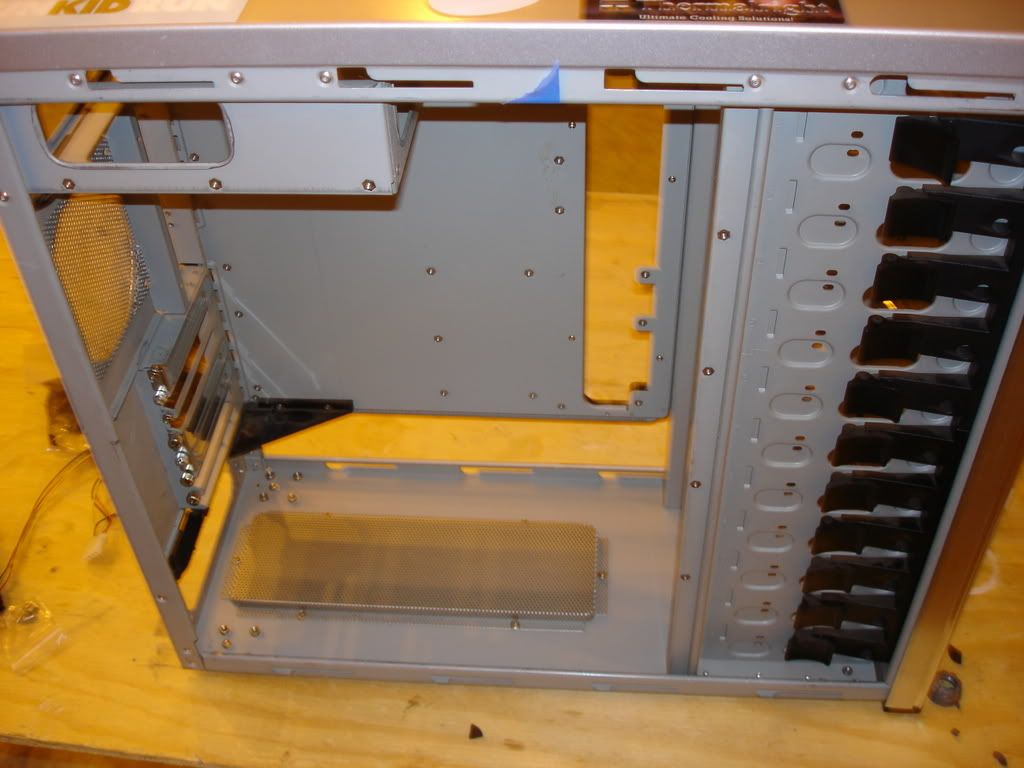

Here's the before and what I'm working with:

#1

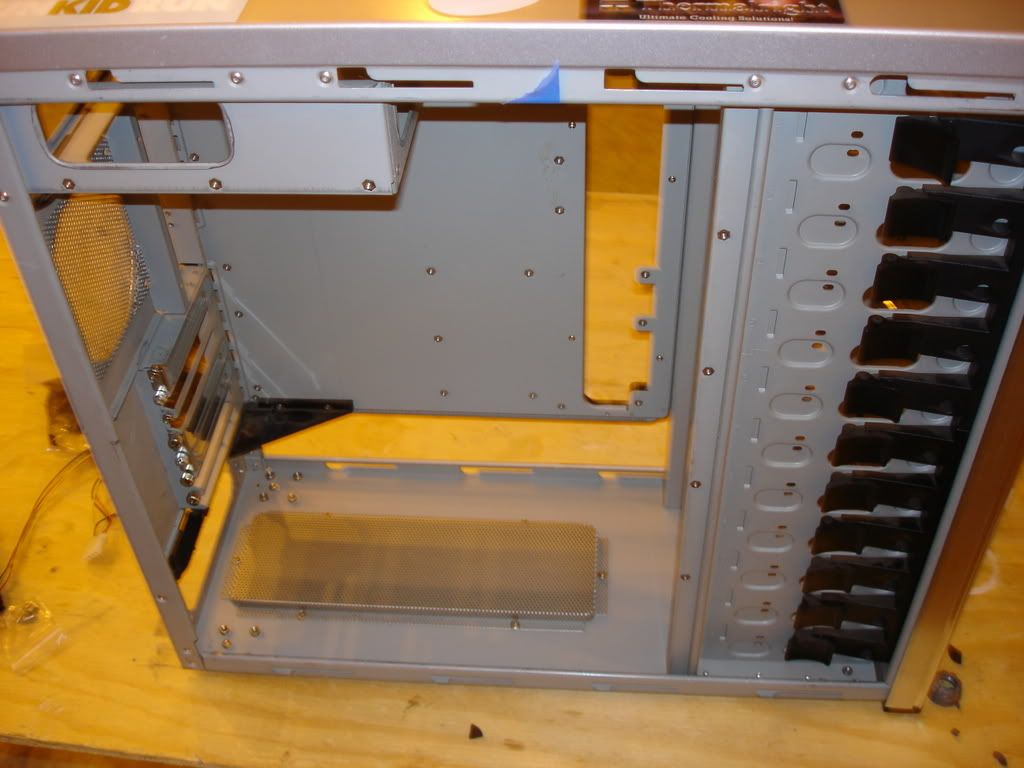

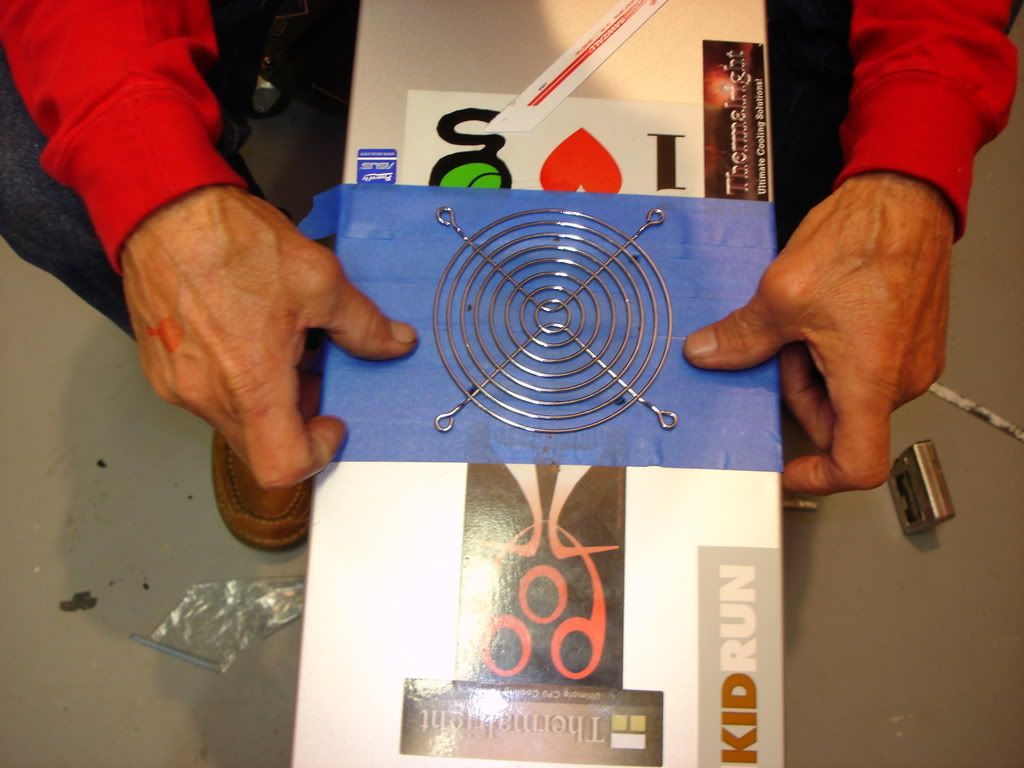

Stripped down:

#2

#3

#4

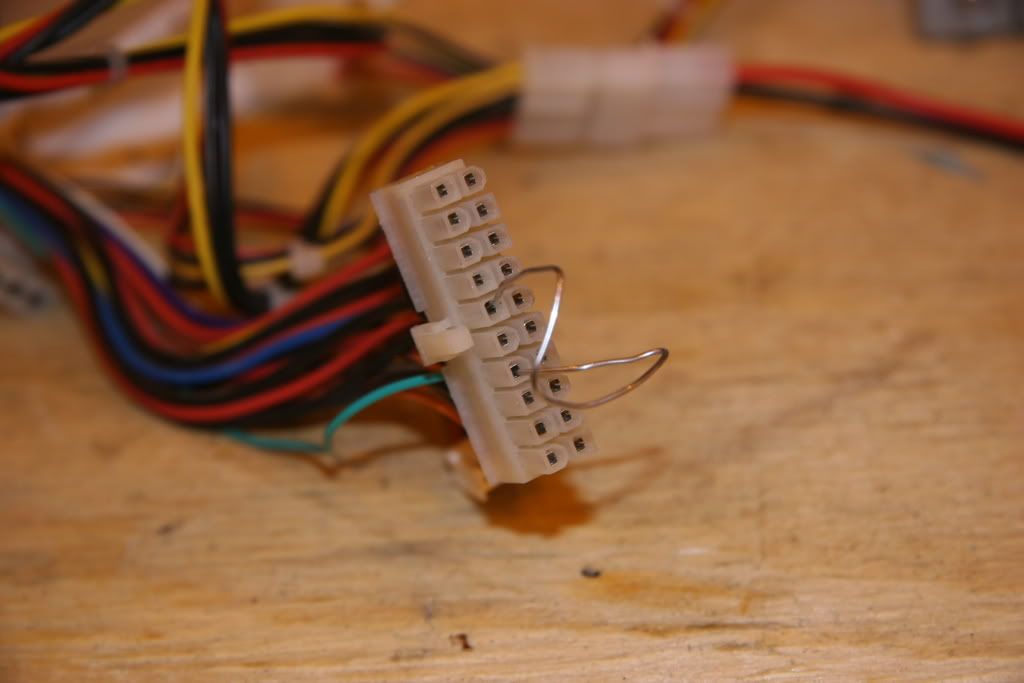

The Gear:

#5

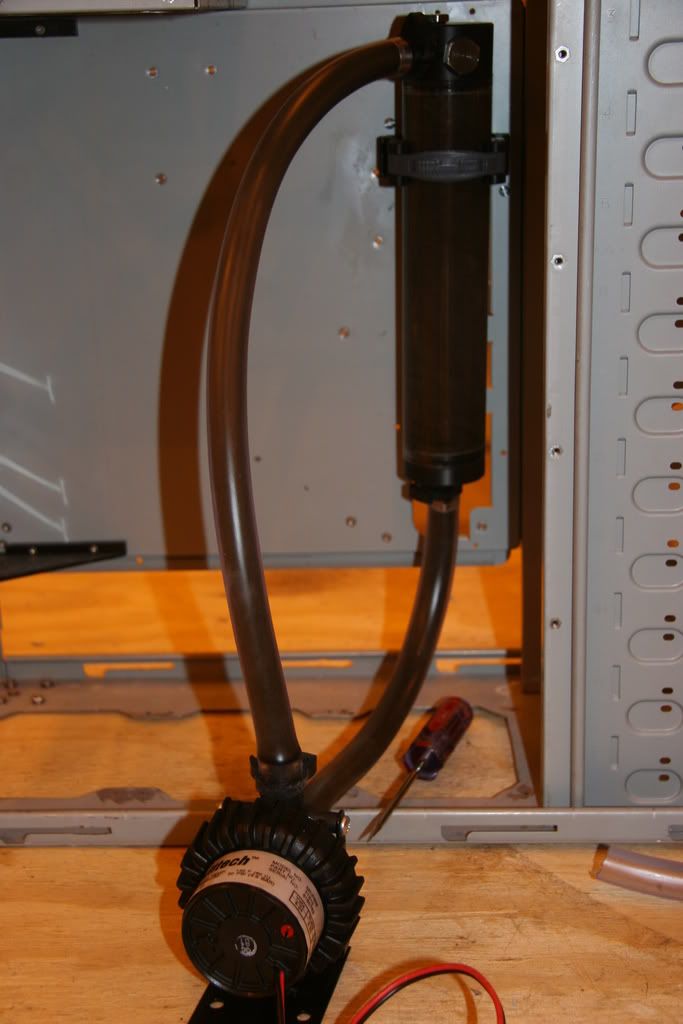

Let's get this show on the road!

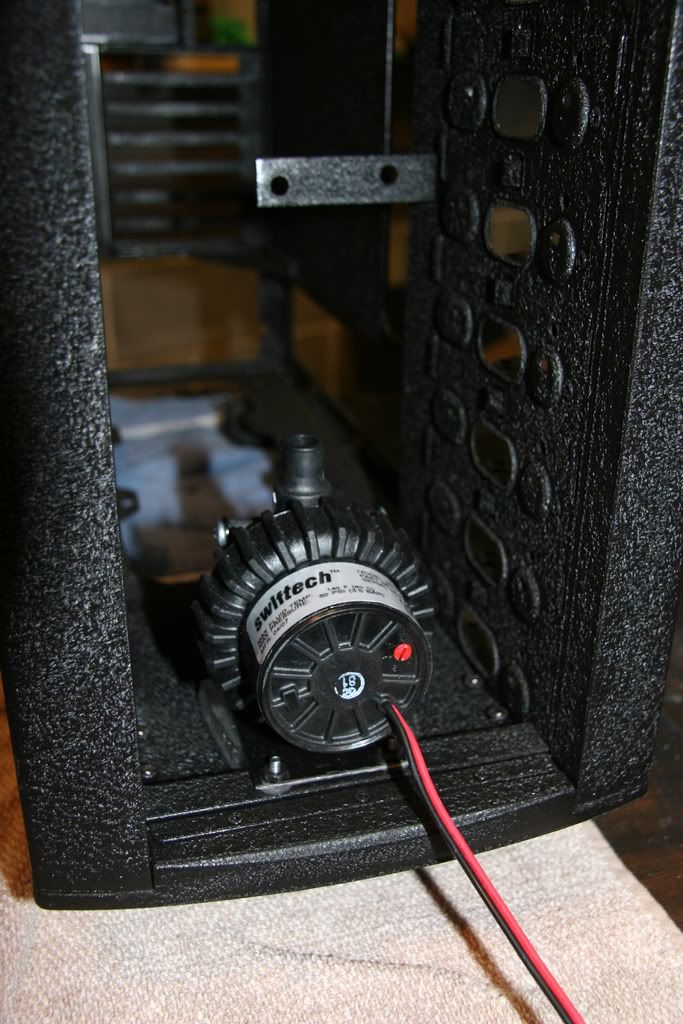

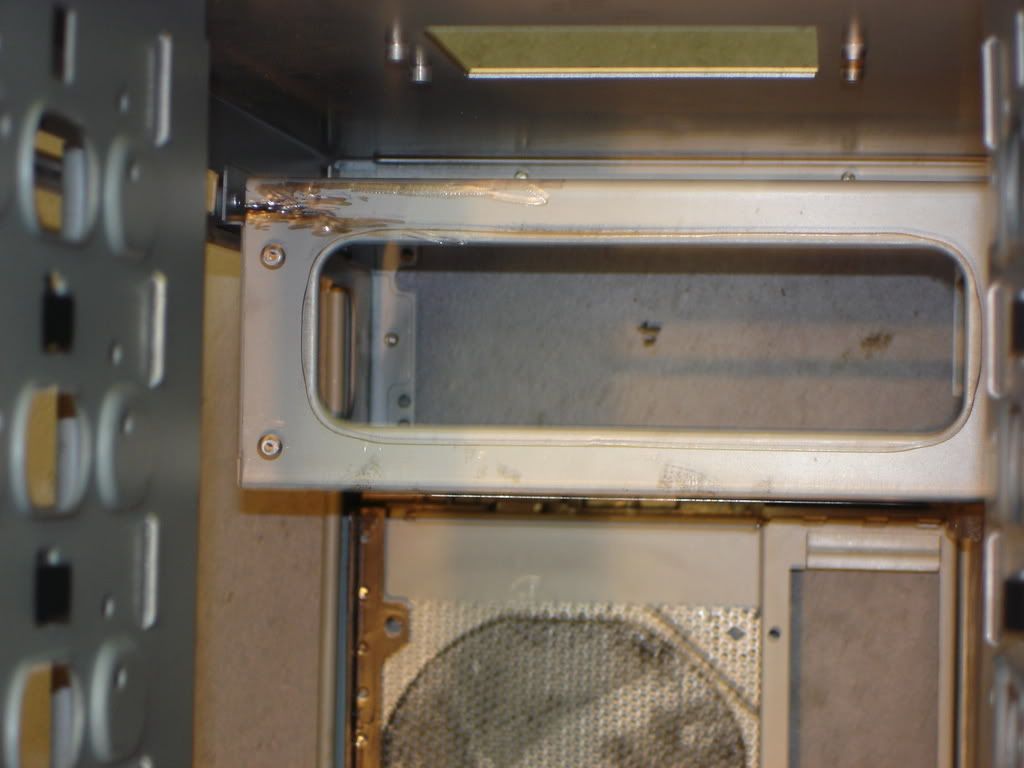

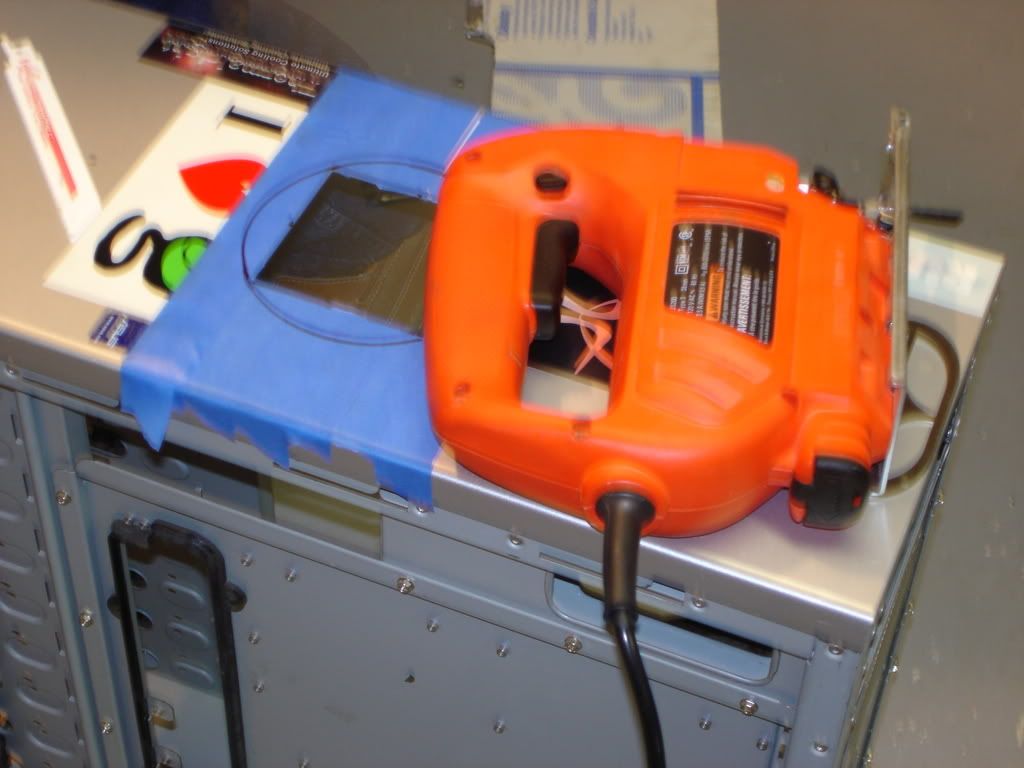

First off, I want to turn my 80mm top exhaust into a 120...

The PSU cage was going to be a problem because the fan will not fit in between the gap. Don't worry about the cut in the top of the cage already, I was experimenting with a dremel bit, lol.

#6

Next...

#7

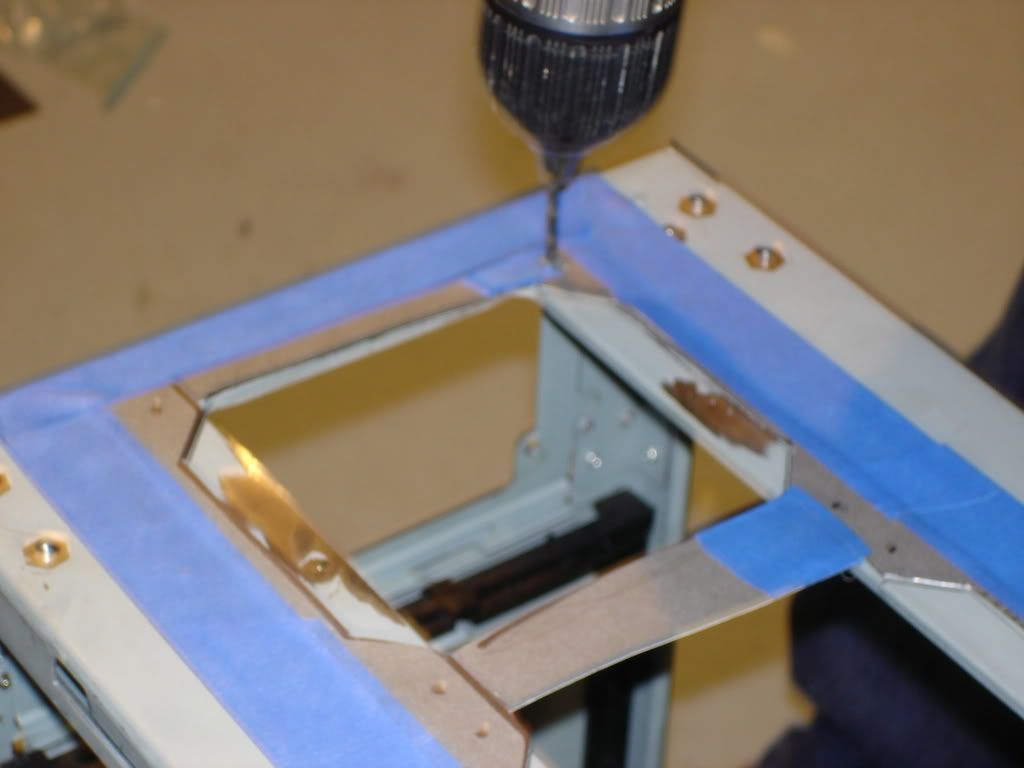

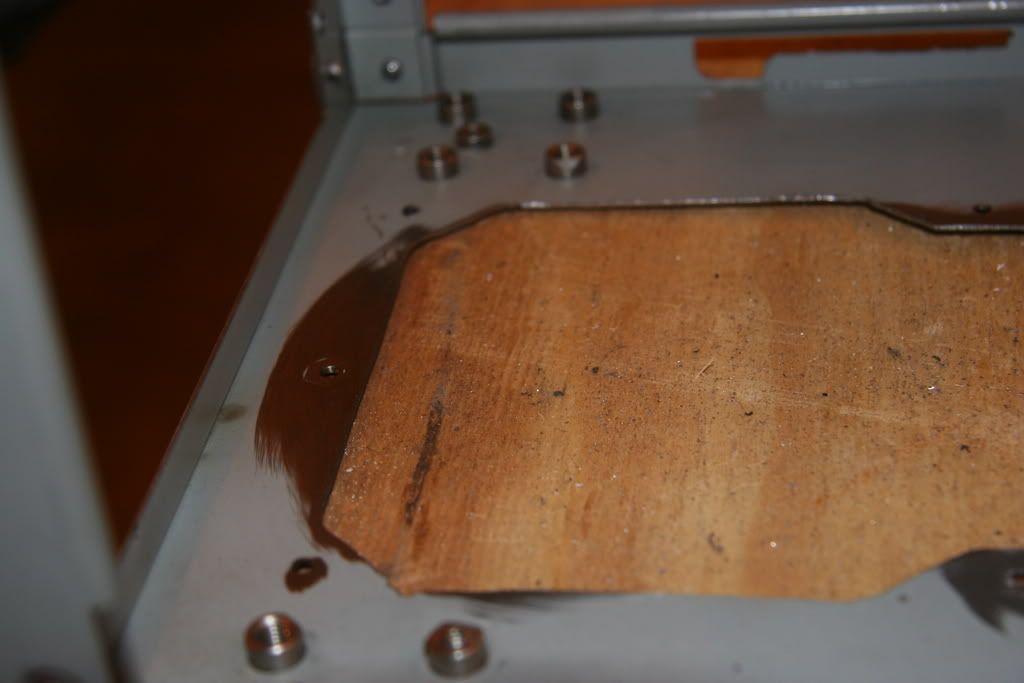

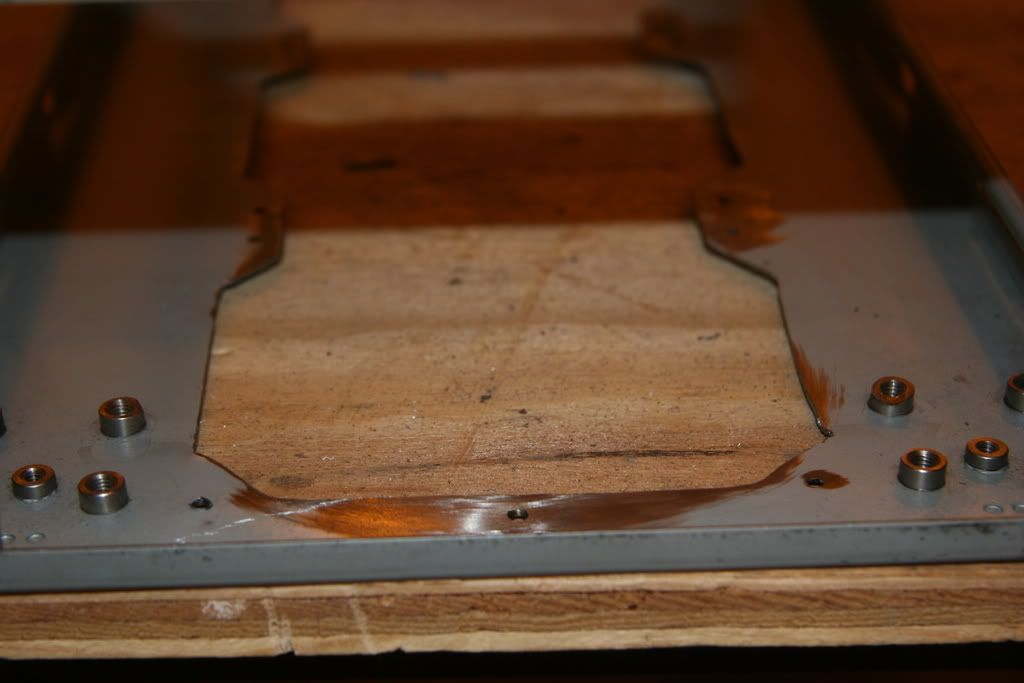

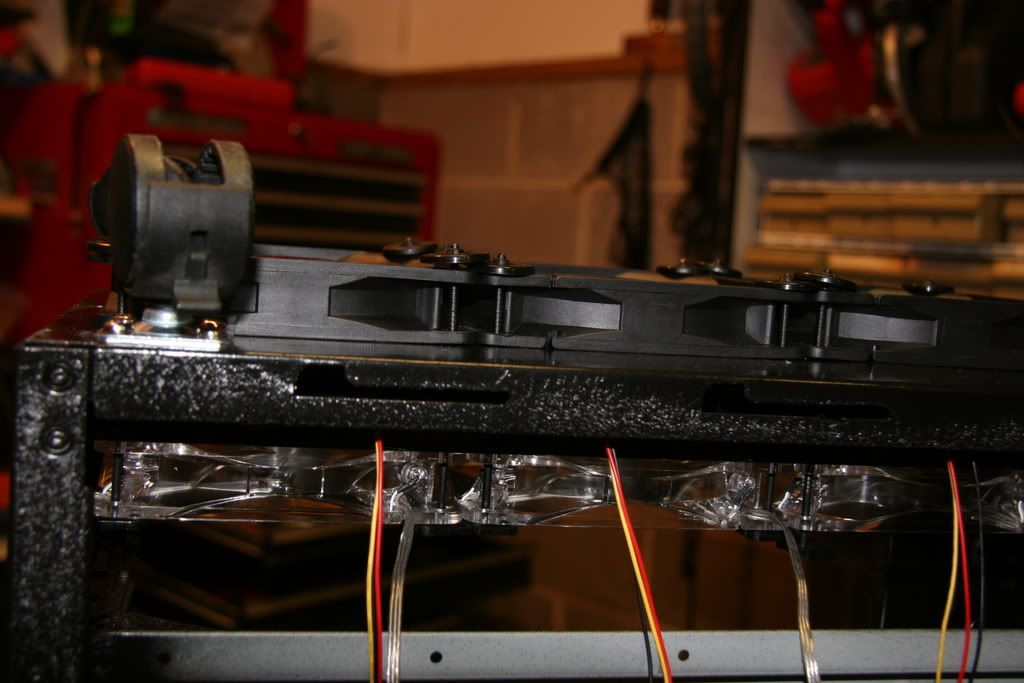

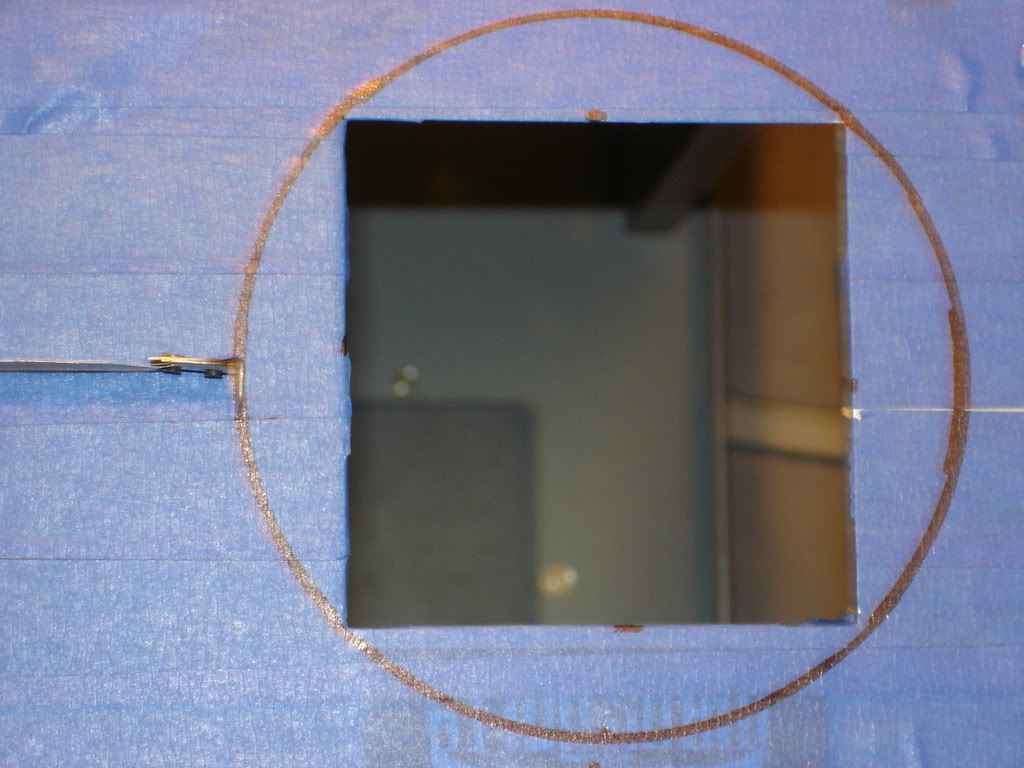

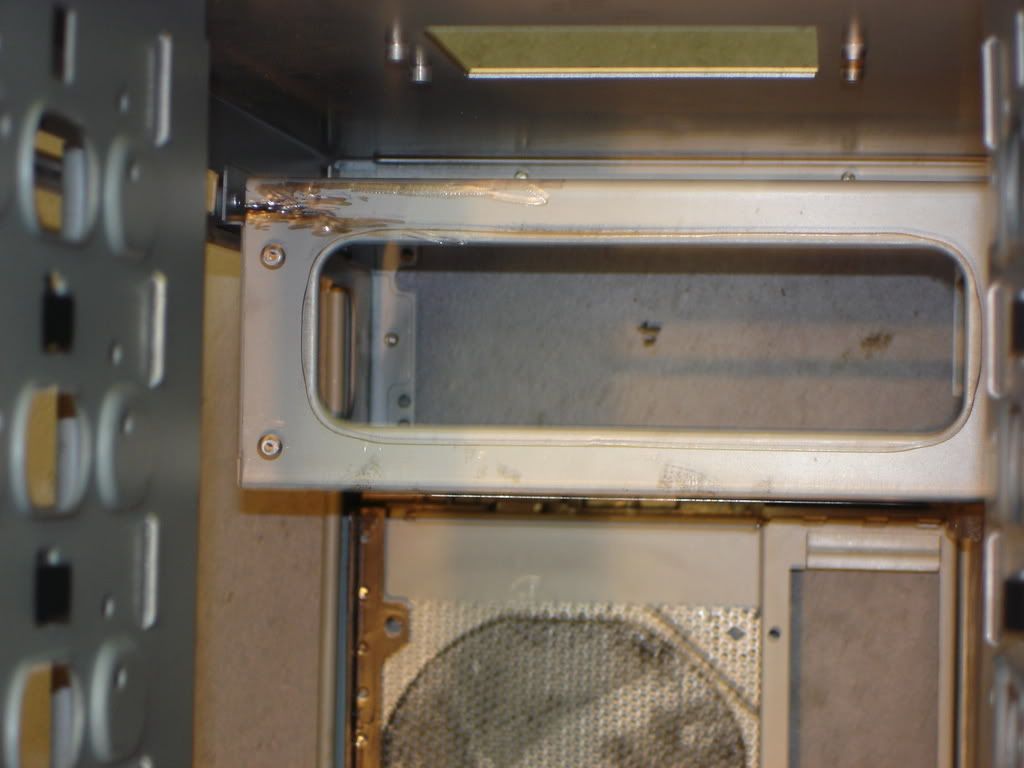

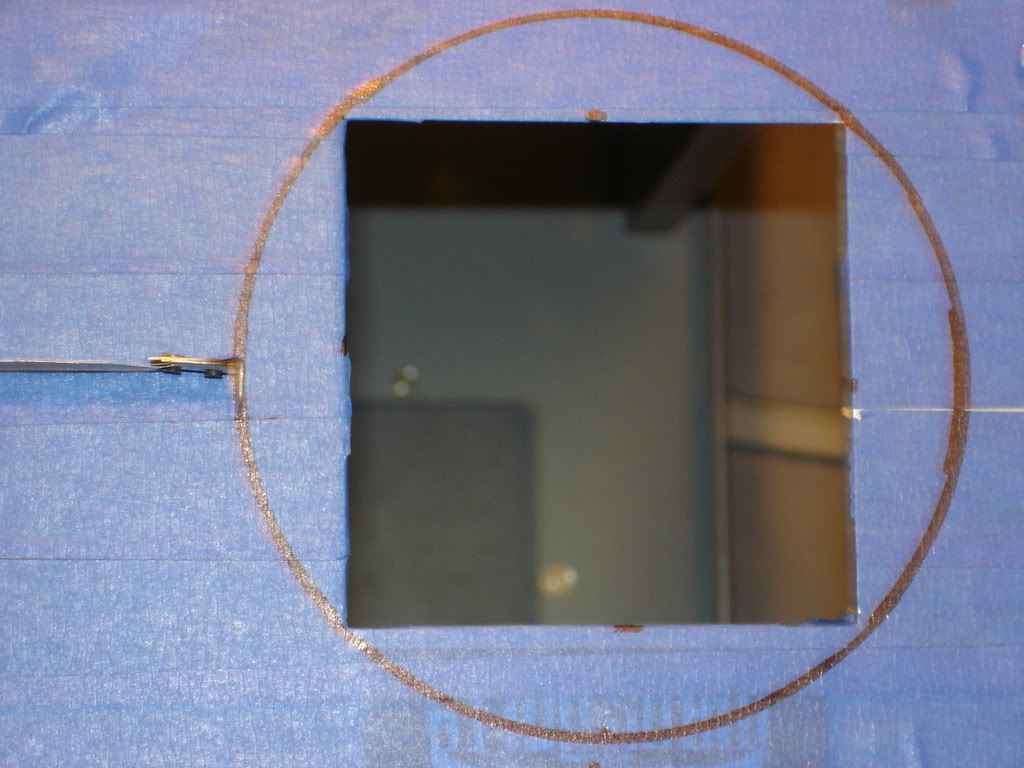

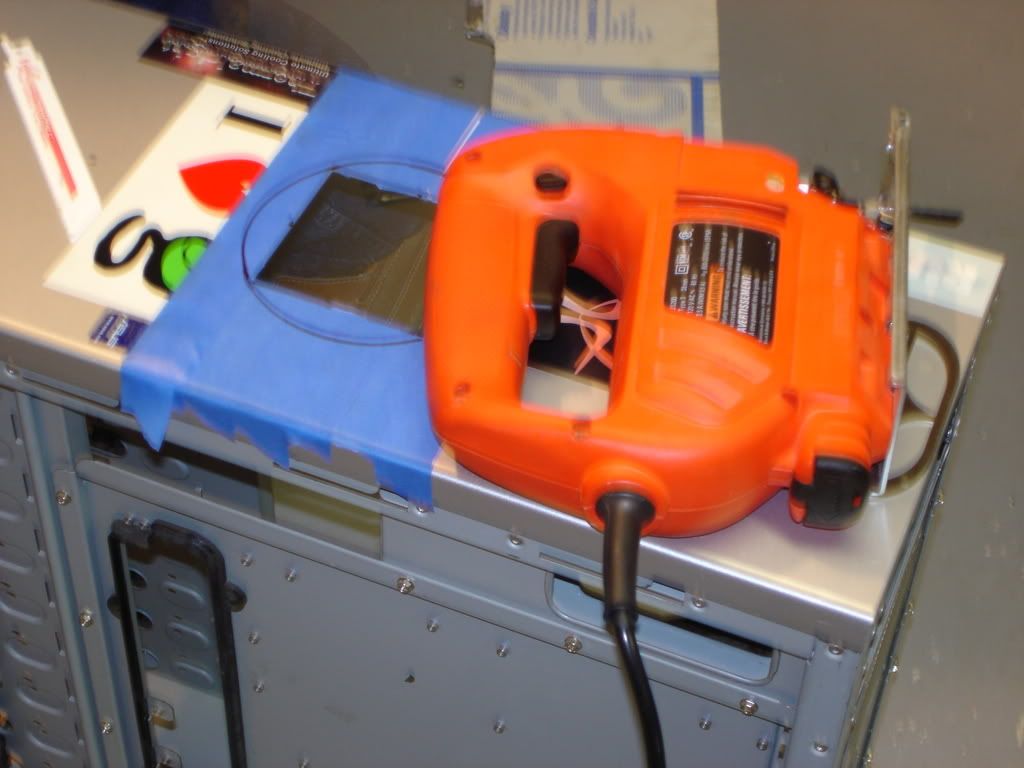

Now the cutting process starts.

#8

Remember to measure! I didn't show that pic but it is measured to the center here!

#9

#10

Sorry about the blurriness, I didn't have my DSLR on me. Future pics won't be so bad!

Future pics won't be so bad!

#11

#12

#13

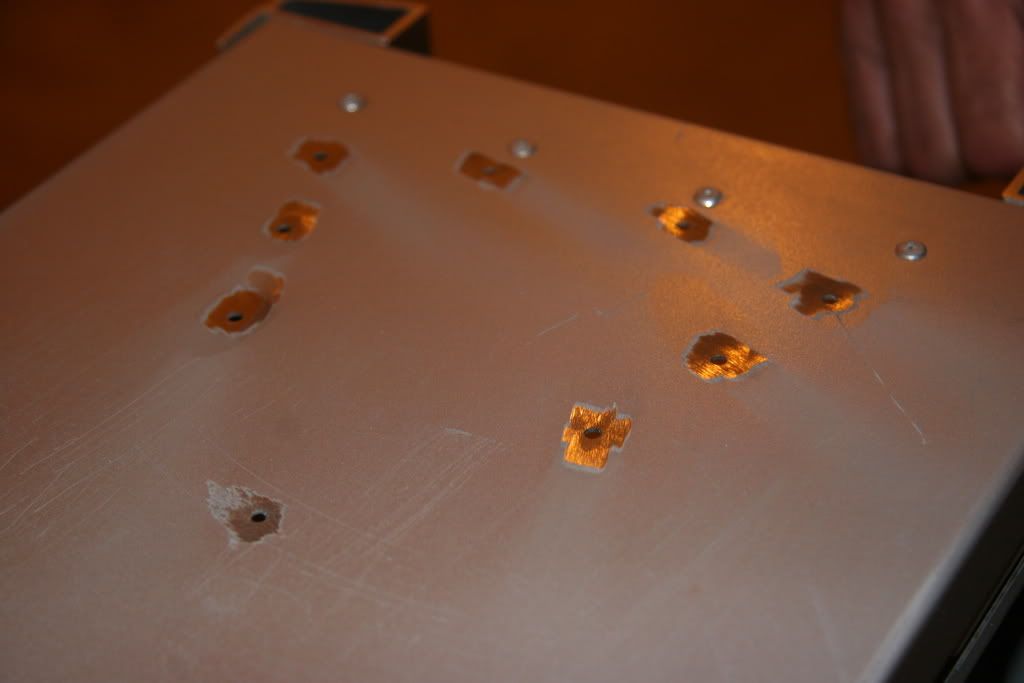

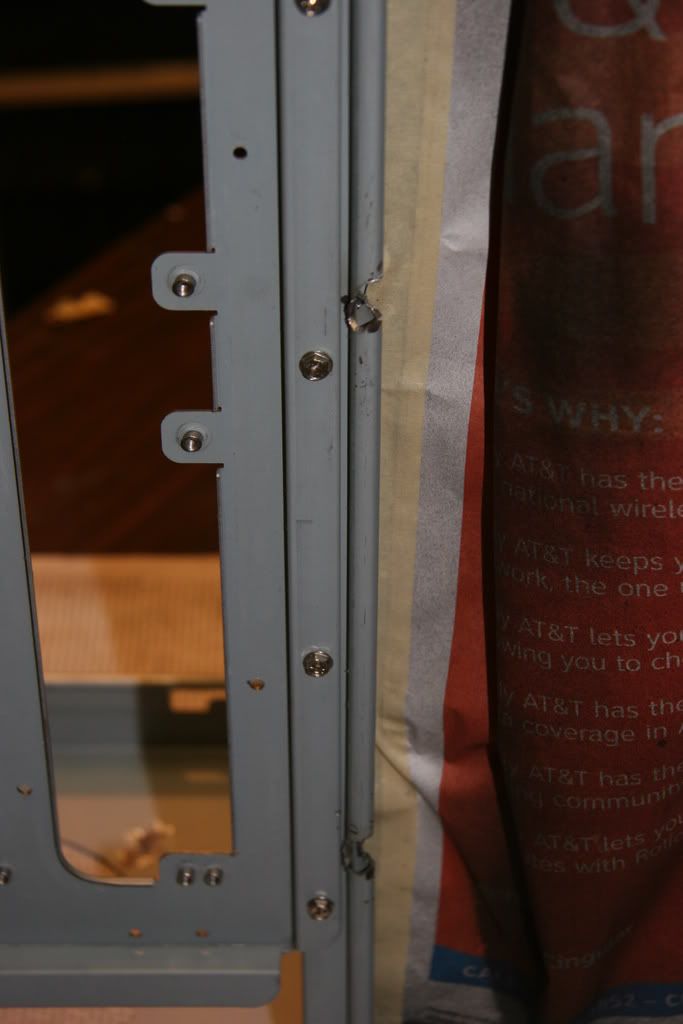

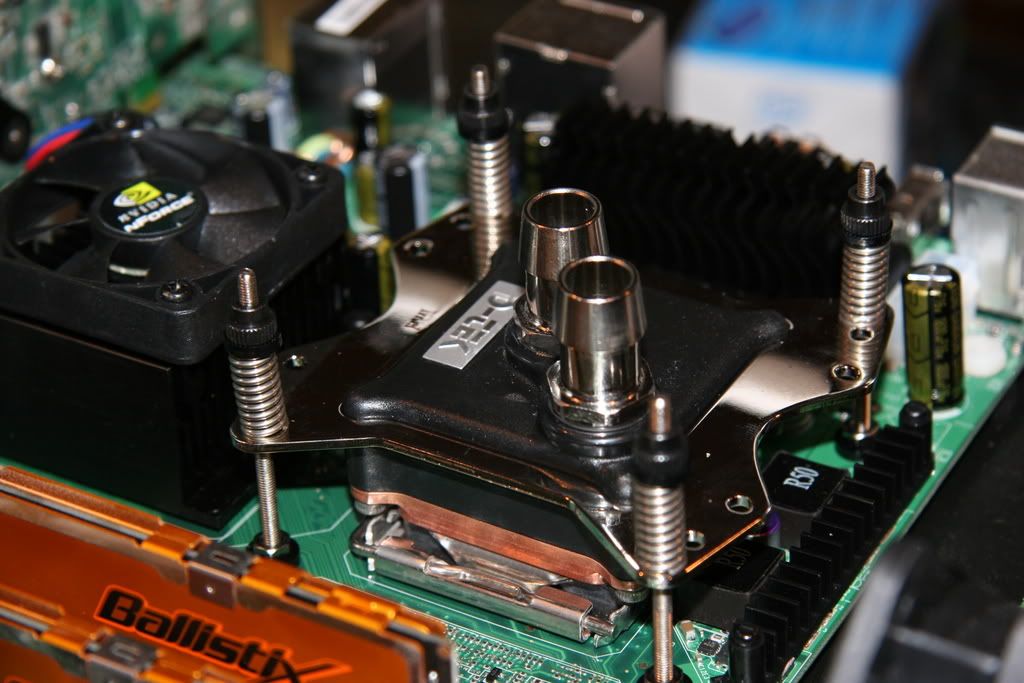

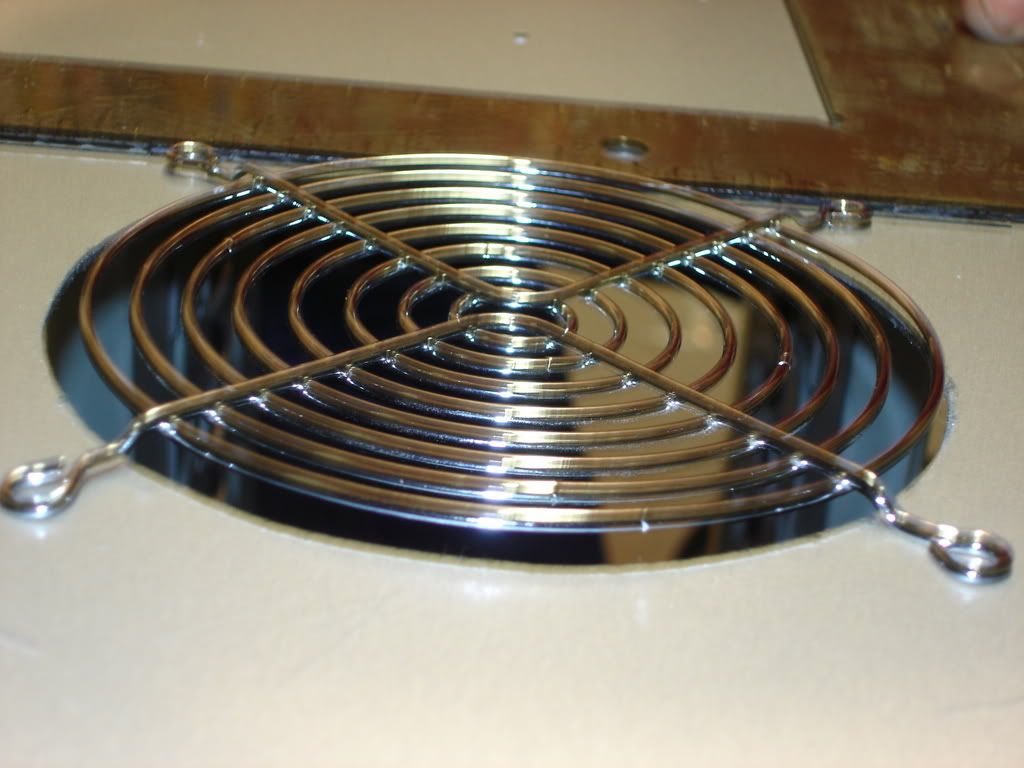

Remember to get squared up!

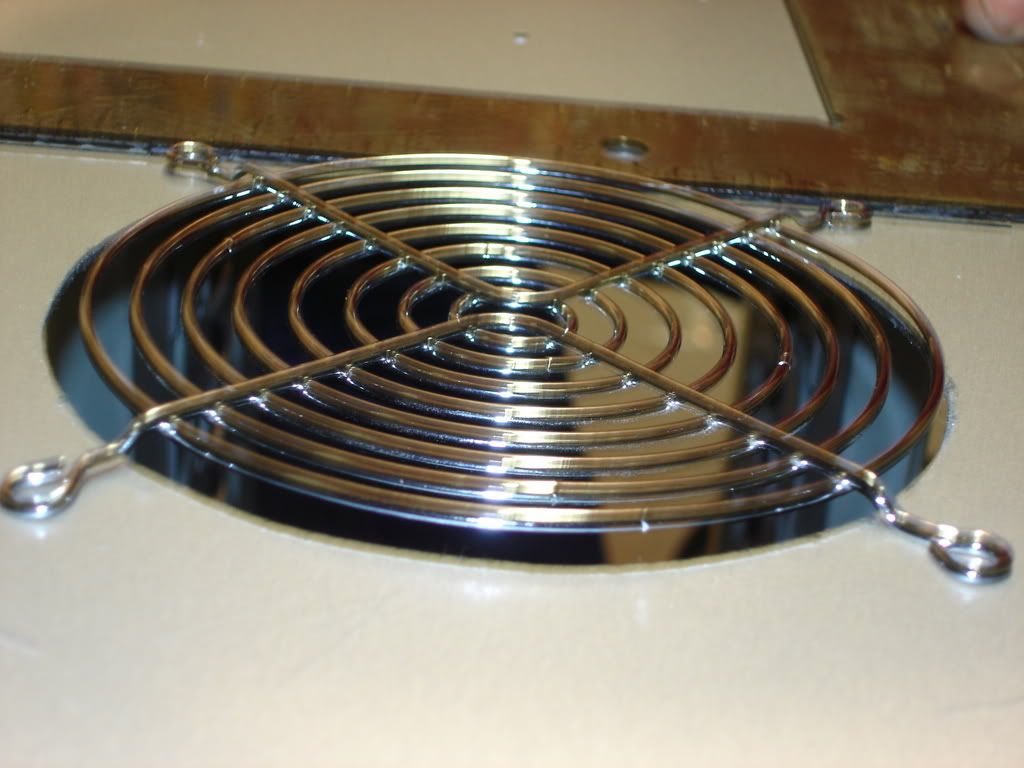

Obviously what we are doing here is getting the hole's centered, we mark them and drill the holes, I didn't think it was necessary to picture that.

#14

#15

More to come, I have most of the radiator done, but I'm really tired of image codes and want a little bit of feedback before I start posting more.

Thanks!

It will also be painted.

I'm going to number every picture so it's easy to reference if you have a suggestion or comment.

And btw, I don't have 3 arms, my dad is doing some of the work so I can take pictures of the process, but I am doing most of it. I just wanted to get pictures of the actual n00bie techniques I used for this project.

Here's the before and what I'm working with:

#1

Stripped down:

#2

#3

#4

The Gear:

#5

Let's get this show on the road!

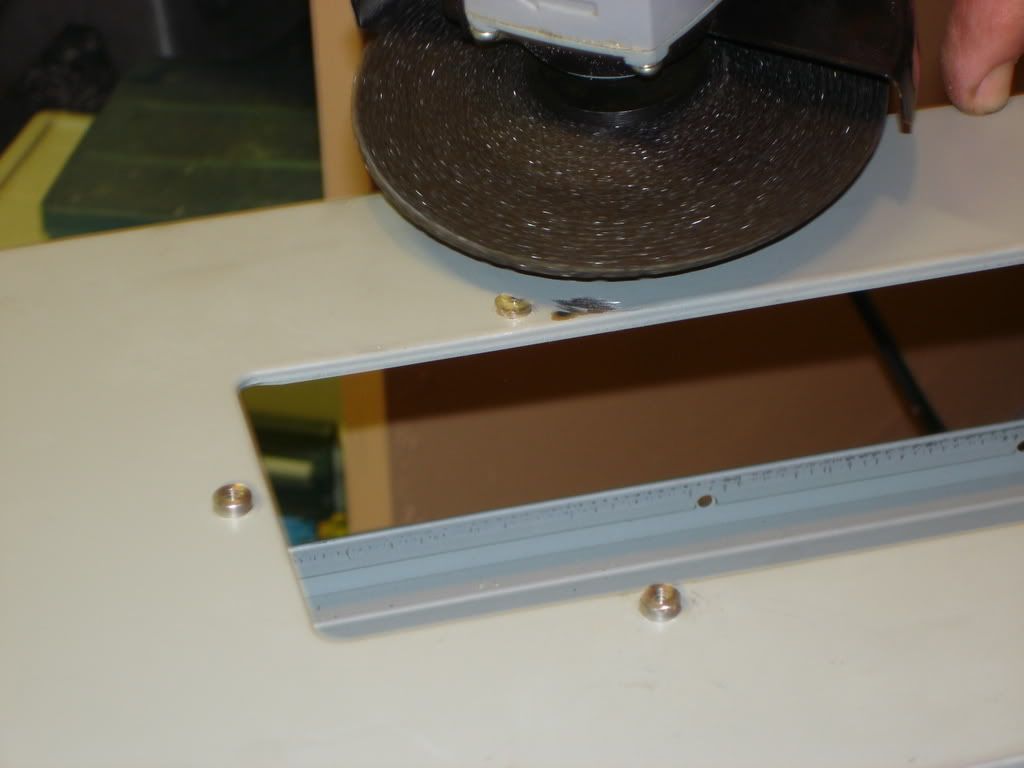

First off, I want to turn my 80mm top exhaust into a 120...

The PSU cage was going to be a problem because the fan will not fit in between the gap. Don't worry about the cut in the top of the cage already, I was experimenting with a dremel bit, lol.

#6

Next...

#7

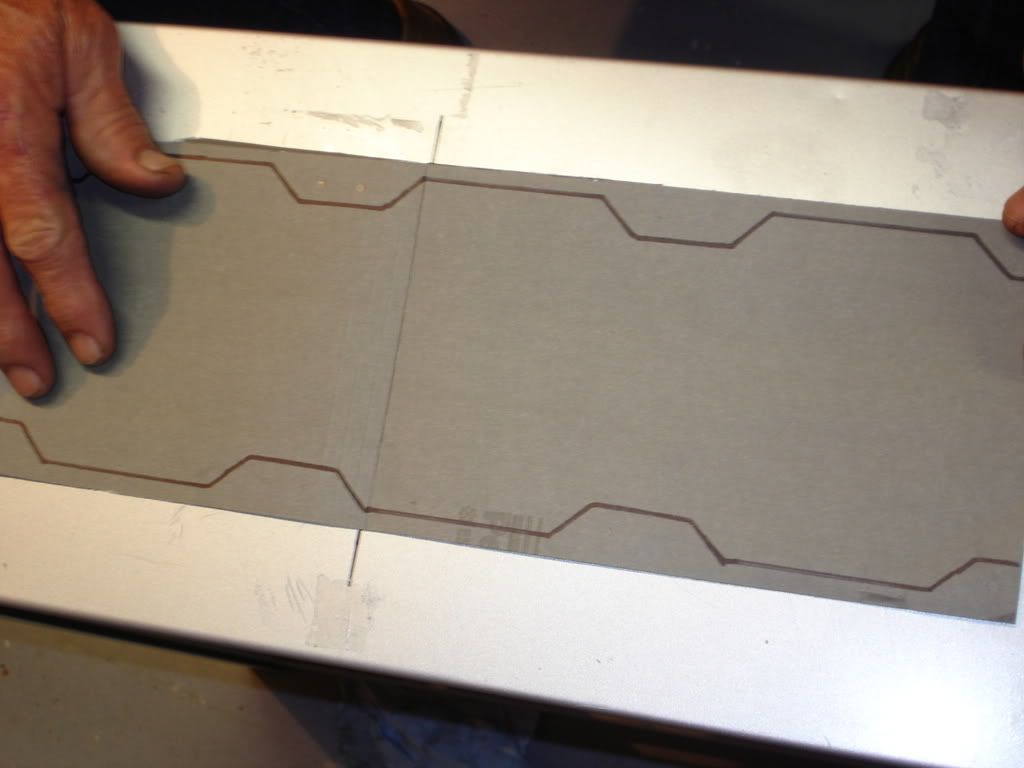

Now the cutting process starts.

#8

Remember to measure! I didn't show that pic but it is measured to the center here!

#9

#10

Sorry about the blurriness, I didn't have my DSLR on me.

#11

#12

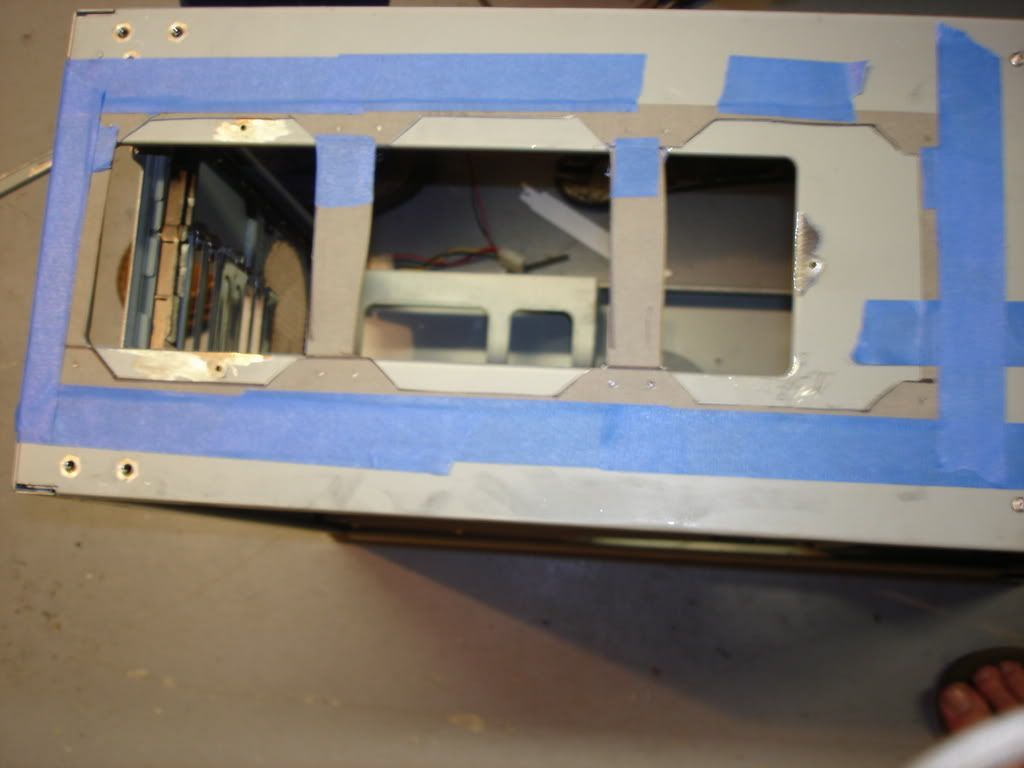

#13

Remember to get squared up!

Obviously what we are doing here is getting the hole's centered, we mark them and drill the holes, I didn't think it was necessary to picture that.

#14

#15

More to come, I have most of the radiator done, but I'm really tired of image codes and want a little bit of feedback before I start posting more.

Thanks!

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)