I will start today by thanking Brian from PrimoChill for providing the lab with our test sample. To say the Typhoon III is one serious example of "outside the box" thinking is almost an understatement. A few lab records were shattered along the way, and one of those was broken by Brian. Normally, I get the first (of many) emails asking when the testing and review will be done within 3 or 4 days of receiving the product (it takes a bit longer to do the type of extensive testing we do after all). Brian's record is never. Not one email. Oddly enough however, I think this made the pressure to get done even worse.

I also want to thank Geno (aka: BoxGods) who designed the Typhoon III for making himself available to answer my plethora of questions. I am obviously fascinated by water cooling and having unlimited access to the designer provided a lot of interesting insight into the process, design goals, and technical details of the Typhoon III.

Full Review

Intro

For those not familiar with PrimoChill, they have been actively designing and selling us water heads products since 2001. They have recently begun to push the envelope with several products including their PrimoFlex PRO LRT tubing, unrivaled in terms of bend radius and selection, as well as a full line of fluids and new polycarbonate compression fittings, which are also included with the Typhoon III.

I first stumbled upon pictures of early prototypes of the Typhoon III (aka: T3) several months ago while planning Laing D5 tests. In my early discussions with BoxGods, he was very focused on the usability of the T3. Almost adamant, he went so far as to build a small acrylic test stand for me that held the T3 in the same location and orientation it would normally be in when installed in a case. What really stood out about the Typhoon III was the different approach BoxGods took. While most are producing a replacement pump top with maybe some inlet/outlet options, the T3 veers off in an entirely different direction. And from those early discussions it was clear the goal of the T3 was to make a pump and reservoir that was very easy for novice users to install, setup, and use...well noobs need love too right?

One of the most touted features of the T3 is the ability to run two independent loops off the same D5 and reservoir. Any hardcore user knows how hopeless that is from a performance perspective, right? One forum poster even claimed he would rather go back to air cooling than run two Y split loops off one pump. In retrospect, I am quite glad I never posted any of the jokes about running parallel loops off the same pump that occurred to me when early images of the T3 began popping up because, while it may have been one of the designer's goals to build an easy to use setup for novices based on the venerable D5, he also stuffed the T3 with enough high flow magic to distill the term "hardcore water cooler's wet dream" down to "priapism".

Back to the point. As you're going to see when you get to all the data tables and charts (especially in the dual loop tests), the T3 is going to make a lot of noise in performance circles. So much so that all those usability features (read noob goodness) are going to get lost in the commotion. With that in mind, I have split this review into two parts. The page you're reading now is all about performance. A second page discussing the usability features built into the T3, like the dual front fill ports, overflow basins, etcetera etcetera--is a must read for the novices. Now shoo, the adults need to talk about important stuff.

Full Review

Dual Loop Capability

As I said earlier, every water head knows that if you take your favorite D5 pump top and add a "Y" fitting a few inches out from the inlet and another from the outlet port you are going to split the flow and pressure which means a big hit to your potential cooling. So how does the T3 not only get away with it, but excel at it?

I will start with the unique pump expansion chamber, cleverly abbreviated PEC, which is directly adjacent to the pump heads 360 degree deep-draw helix--close enough that it actually straddles it really. The PEC is proportioned and placed to take the water fed through the primary pump head outlet and let it "expand" before being fed out the back into either one or both secondary outlets. Although I am no mechanical or hydrodynamics engineer, I am told that in addition to splitting the flow evenly between the two ports (no easy feat, +1 T3) it works as a sort of pressure regulator. In order to increase flow into this expansion chamber the primary outlet is almost double what you find on other pump heads.

So now we have increased the amount of water the D5 can push out with deeper draw and a larger outlet, and even given it a place to go that helps regulate (and maintain some of) the pressure. Again, you don't have to be an engineer to know that if more water is being pushed out then you need to draw more water in through the inlet or you starve the pump and a nosy neighbor calls pump protective services on you. Feeding the inlet is a large "tank" that is, in turn, fed by the inlets on the back of the T3 that you connect your loop or loops to. The problem is that the inlet diameter is precisely matched to the impeller in the D5 and any change in diameter kills performance. An area that has long been considered the biggest limiting factor on gaining any more performance out of the D5. At this point the discussion turns to laminar boundary layers and feed angles and stuff that Vapor and the engineering types wax on about at length. Fortunately for most of you, I barely understand it, so you do not have to read my poor attempt at explaining it. BoxGods tried to explain it in layman's terms for me by saying:

"Although water is not compressible in the very limited pressure ranges we are working in, it CAN be redirected and moved in a more efficient manner similar to a venturi. I actually got the idea to try it from an article by Martin (from Martin's Liquid Labs =)) where he suggested (amazingly based just on observation) that although the impeller on the D5 was obviously optimized for maximum efficiency, the inlet feed angle didn't seem to be. In simplified terms this means that although the inlet diameter and the impeller are matched for efficiency, the perpendicular inlet angle dictated by the tubing type fitting is actually pretty bad."

In the SolidWorks images below you can see that although the outlet is still the same size, it has been "humped" into an efficient hydrofoil cross section and the trailing edge is very sharp. In effect, a low pressure venturi that accelerates the water entering the pump so that a larger volume can pass through. It is also fed into the pump's impeller at a much more efficient angle.

All of these tweaks on the inlet, outlet and PEC are balanced to provide the best possible increase in potential flow rate without sacrificing head pressure, and are the true genius behind the Typhoon III. The "Y" fitting method mentioned earlier happens before and after the pump. In the T3, the PEC and reservoir are essentially a part of the pump head, so much so that you can think of the loop split happening inside the pump, which is why you are going to start seeing the term "through the pump" a lot more often from now on in water cooling. Hopefully, with this explanation, you will no longer look at the T3 as just a bay reservoir with a pump attached to it. If you do, you are overlooking a major evolution to our previous LC loops.

In the first frame of this SolidWorks image, the PEC is shown with its cover in white, so you get a better view of the relationship between the PEC and the pump head. In the second image, the white cover is removed for a peek inside, and in the third image a .30" diameter circle, shown in blue, demonstrates the size difference between the primary outlet on the T3 and a standard D5 pump head. You also can get an idea of the "humped" shape of the inlet and its razor sharp leading edge.

The same area from the opposite side shows the positions of the in and out ports relative to each other and the primary inlet and outlet.

Test Methodology

Test methods and specifications have been removed from the product review pages to ease the torture my reviews inflict on your mouse wheel finger. You can find the test process, methods and explanations of how to read the charts and tables using the link below.

- skinnee labs Pump Test Method / PQ Curves

Test Results

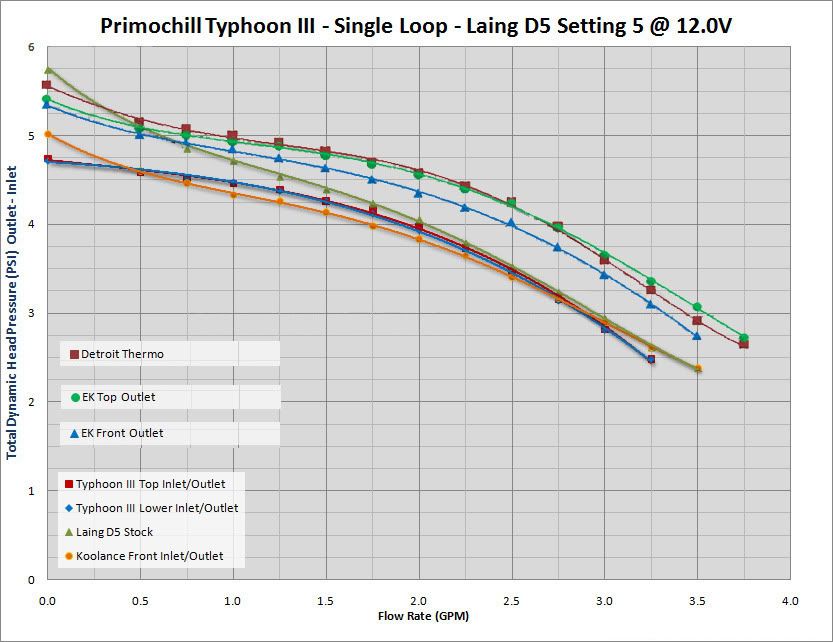

Okay, I have finished holding back the eye candy you crave from our reviews Here are the compiled scatter plots for Typhoon III single loop--tested at Speed Setting 4 (D5 Basic) and Speed Setting 5 (D5 Vario). For the single loop configurations, I have included the stock impeller housing or top along with the comparable Koolance top with Front Inlet/Outlet configuration. A large portion of the testing was focused on the dual loop configuration of the Typhoon III and, to be candid, I don't think my scatter plots truly tell the story of how incredible the Typhoon III is with the dual loop configuration--but more on that after the single loop scatter plots. Below each scatter plot is the test data for each inlet/outlet configuration at the specified speed setting. The Performance Results Intro explains how to read the charts and the explanation of the data if you find yourself scratching your head.

Setting 5 Top Inlet/Outlet - Setting 5 Lower Inlet/Outlet

Setting 4 Top Inlet/Outlet - Setting 4 Lower Inlet/Outlet

The single loop charts are nothing new if you have read pump reviews before, as I said, it is easy to get caught up in the performance of the dual loops configuration, but as you can see above, the T3 is competant in the single loop department too. Nothing to write home about, but no slouch either, comparable to the Koolance top or sticking with stock. Though I look at a single loop as someone just waiting to upgrade and go for dual loops. Running two loops off a single pump was taboo on the hard core, more serious cooling forums. Well, the Typhoon III changes the game up bringing the capability of running dual loops without kissing your loop (both of them) performance good-bye.

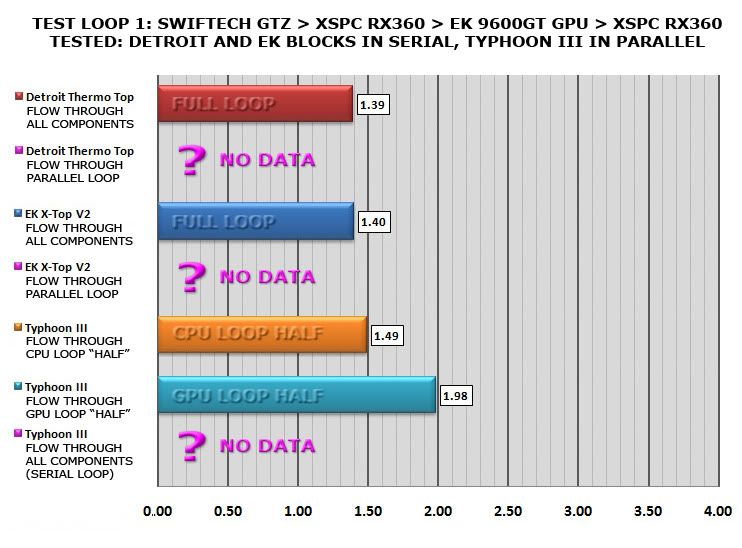

As you are reading this next chart, be sure to keep in mind that these are only the pressure measurements on one of the running loops, the other loop is adjusted to a specific flow rate and maintaining its own head pressure. I could not come up with a good way to display this concept visually, so I have to rely on my non-engineer speak. Separating out one long serial loop into two loops, you reduce the amount of restriction that serial loop has to overcome. Reducing restriction means a higher flow rate which actually boosts the efficiency of the pump back up the performance curve.

Vapor and I were trying to get a remixed version of Martin's Flow Estimator ready for this review so you could play with the numbers between single loop and dual loops on the Typhoon III yourself, but we're still working the kinks out even though Vapor has worked the equations every way from Sunday. What he came up with and the explanation are posted at XtremeSystems. We hope to have the Flow Estimator (currently named Loopilator) ready for release soon, and will post on the main page when it is available.

As I mentioned previously, thanks to the PEC and its pressure regulating function, the top and bottom ports are so closely matched for output that you can choose whichever one fits your loop layout needs the best--chalk another one up to the PEC.

Okay, okay, enough of my blabbering...on to the dual loop PQ Curves.

Top Inlet/Outlet, 2nd Loop @ 0.5GPM - Lower Inlet/Outlet, 2nd Loop @ 0.5GPM - Top Inlet/Outlet, 2nd Loop @ 1.0GPM - Lower Inlet/Outlet, 2nd Loop @ 1.0GPM

Top Inlet/Outlet, 2nd Loop @ 1.5GPM - Lower Inlet/Outlet, 2nd Loop @ 1.5GPM - Top Inlet/Outlet, 2nd Loop @ 2.0GPM - Lower Inlet/Outlet, 2nd Loop @ 2.0GPM

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)