Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

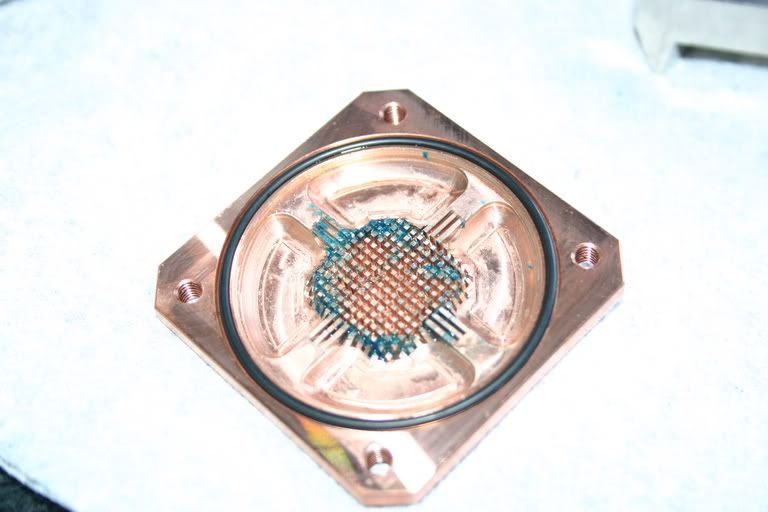

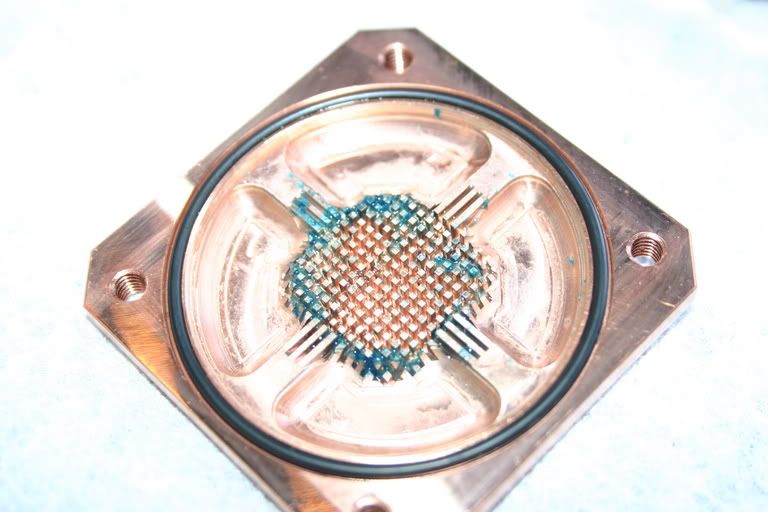

The reason to clean Cuplex Blocks..pics

- Thread starter theseeker

- Start date

DFI Daishi

2[H]4U

- Joined

- Feb 14, 2005

- Messages

- 2,839

nice reef.

DFI Daishi said:nice reef.

Thanks.

yang88she said:wow, I'd usually ask for more pictures of your system, but how about more pictures of your tank set up. That looks absolutely amazing, and looks incredibly expensive

Thanks, check out my album at photobucket.com

Top Nurse said:I'm glad you posted those pic's of the XT. For some strange reason no one ever listens to me when I suggest that they clean out the A-C blocks before you use them.

I did, and I am glad TN! Thanks....

Top Nurse said:I'm glad you posted those pic's of the XT. For some strange reason no one ever listens to me when I suggest that they clean out the A-C blocks before you use them.

Why does one need to clean a new from the factory cpu block??

Or am I missing something here???

plywood99 said:Why does one need to clean a new from the factory cpu block??

Or am I missing something here???

Well that appears to be the million dollar question now doesn't it? Why does Aqua Computer ship a block in such a condition that it needs to be cleaned before it's use at the risk of destroying an expensive piece of electronic hardware? Perhaps Shoggy or anyone from Aqua Computer would like to clear up this little mystery?

I have my suspicions as to why this is occuring, but I would rather hear it straight from the horse's mouth.

It just makes no sense for new blocks to be fouled with gunk, whatever the reason. They may make them pretty and to perform well, but fouled from the factory is just rediculous. Do the directions mention cleaning the block before installation?

Shoggy said:AC is using glycerol for mounting the seal ring. Maybe that stuff is causing the problems with gridlocked nozzles inside the block.

I always clean up everything before I use it.

IMHO the problem is probably not related to the use of glycerol. Reason being is that the while the o-ring may be treated with glycerol it sits in it's own little machined groove unless of course they are slopping the stuff on with a paint brush.

R1ckCa1n had a similar problem in that his XT made a sudden jump in temperature of about 3-4 degrees Celcius over the course of one day! As I had already suggested to him that he clean the XT he also took his apart. On his XT some of the jet nozzles in the accelerator plate had become fouled with the same green colored stuff as I found in mine and as you see above in the pics shot by theseeker. It is my theory that the jet nozzles in R1ckCa1n's XT became fouled after that green gunk in the copper baseplate broke loose after several days of use and migrated through the water loop and became deposited in the accelerator nozzle plate.

I think the problem is that these Cuplex XT's are machined with a water soluable coolant which is not being taken off during the manufacturing process. I should point out that it is common practice in the machining of components to leave this stuff on as it helps protect the metal while it is stored during the various manufacturing processes. However it is inexcusable to not at some point before assembly to use a degreaser on the components and to clean out any metal chips from the block. BTW, this problem does not seem isolated to the Cuplex XT as I have seen pictures of the Cuplex Pro nozzles with the same kind of problem. My TwinPlex also had the same green stuff on it though not to anywhere the same degree. Certainly it is not the high quality product that we have come to expect from Aqua Computer.

Till Aqua Computer can identify the problem in their quality control process and correct the problem it would be my assumption that the importer, Sharka Corp, will properly clean these blocks and reassemble them prior to shipment so this problem does not affect their customers. BTW, yesterday I dispatched an e-mail concerning this to IT-Trade, Aqua Computer, and Sharka Corp. I have already heard back from Franz at IT-Trade and he is quite concerned about this and will follow up with Aqua Computer tomorrow morning.

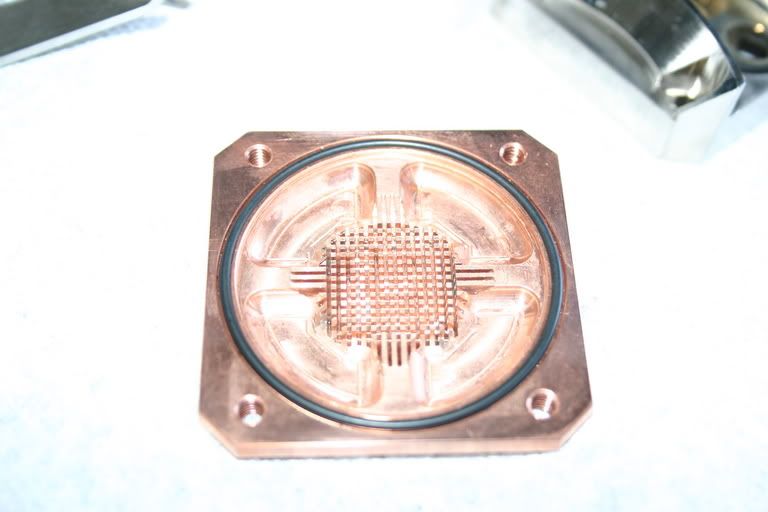

For those who already have Aqua Computer water blocks or they are in shipment you should do this inspection immediately. The easiest way to clean up this problem is to disassemble the block by unscrewing the four (4) mount screws. Then the block comes easily apart and you can separate all the components. I would suggest getting an old toothbrush and some isopropyl alcohol and vigorously scrub the copper base plate and then blow it off with compressed air. The nozzle accelerator plate can be cleaned by soaking it in alcohol and the blowing out with compressed air as well. If you want to be absolutely sure I would suggest using something like a pipe cleaner that you can get at a craft or smoke shop to clean out the nozzles though I didn't try this myself. Aqua Computer does not recommend the use of alcohol on the plexiglas parts, though that is what I used on mine so Caveat Emptor if you decide to do as I do!

A solution to this problem, if the issue is of leaving something on the metal to protect it, is to simply spray the block with a diluted mix of AC Fluid and distilled water. This seems like a no brainer to me as the AC Fluid is designed to prevent corrosion and is native to the Aqua Computer water cooled system. Thus there would be no need to even think about cleaning it up upon delivery.

Igg said:Top Nurse, when i get my XT tomorrow, i will open up and let you know if they're dirty or what

It will be dirty.

Well that is good news! I think perhaps the problem is related to quality control. Somebody is slacking on what they are supposed to be doing.

I just got an e-mail from Stephen Wille who is one of the owners and business managers of Aqua Computer. He apologizes for the problem and will get to the bottom of this and fix it.

I just got an e-mail from Stephen Wille who is one of the owners and business managers of Aqua Computer. He apologizes for the problem and will get to the bottom of this and fix it.

From SNT? Was that part of the large order you were going to place?lemmy said:i'm getting mine today too, i'll post a pitcure if i see any dirt

Igg said:if yours is getting dirty after a couple of days then wouldnt it mean there's gunk in your system building up somewhere then being deposited on the fine grates of the block?

Yes there is that to consider as well because the jet nozzles on the accelerator plate would become the easiest place to accumulate junk in the system.. But I opened mine before ever running a drop of H20 through it.

Swimming_Bird

n00b

- Joined

- Jan 25, 2005

- Messages

- 23

if i were here to tell you i would have said i told you so. copper+alluminum in the same system makes the likelyhood of corrotion is increased greatly.

Swimming_Bird said:if i were here to tell you i would have said i told you so. copper+alluminum in the same system makes the likelyhood of corrotion is increased greatly.

What the hell are you talking about?

Igg said:i think he's talking about the aluminum jet inlet and copper base?

If were talking about the Cuplex XT, there is no aluminum on that block!

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)