WarMace

Gawd

- Joined

- Aug 25, 2004

- Messages

- 963

Most worklogs have a set theme, a name that fits in well with the theme, seemingly unlimited budget, and a workshop.

I, have none of those.

What I do have is a tired PC in need of an upgrade, big plans, my ever knowledgeable friends at HardOCP, and the wifes O.K. Mix that together with a little bit of elbow grease, and this may come out looking pretty cool.

The big plan:

A little background.

This is my current PC. Sadly lacking any flair to represent the awesome components inside it for the last 2 1/2 years. Radion x800Pro; Gig of Crucial Ballistix; Amd64; Raptor 74; Asus A8V Deluxe.

This image is not to show you my lousy wiring, its to show the items I hate the most about the CMStacker Case.

Now for the new components.

Sadly, the case is not done (its not even started), and i cannot wait to start tasting the raw power of my new computer. Plus i need to test for DOA stuff. So where does one place $1600 worth of computer guts while waiting for the new case to be completed.....

In a computer case found at the dump of course.

Goodbye 400Mhz, hello 3Ghz!

Cool things you learn every time you rebuild a PC.

Like applying bird-turd' (AS5) is that you want to wipe it around on the heat sink and CPU then gently wipe it off. This fills the pitts. Then you apply a thin line across both cores and let the heat sink spread it with even pressure. I think I added too thick of a bead, Ill redo it when the water cooling stuff is installed.

Comments? Suggestions?

PSU Checks out.

Man these things are bigger in real life!

I feel so ashamed! This will be my inspiration to work fast to complete this mod on time.

Now onto the stuff you've been waiting for, the modding!

First things first is to tear apart the old PC.

All the way apart.

Completely Naked and ready for cutting.

I, have none of those.

What I do have is a tired PC in need of an upgrade, big plans, my ever knowledgeable friends at HardOCP, and the wifes O.K. Mix that together with a little bit of elbow grease, and this may come out looking pretty cool.

The big plan:

- Upgrade my gaming PC to last me another 2 years.

- Finally join the elite overclockers.

- Watercool (the right way this time)

- Fix everything I hate about my case.

- To have all this done in time to show off what might be the baddest looking PC at Noreaster next month.

A little background.

This is my current PC. Sadly lacking any flair to represent the awesome components inside it for the last 2 1/2 years. Radion x800Pro; Gig of Crucial Ballistix; Amd64; Raptor 74; Asus A8V Deluxe.

This image is not to show you my lousy wiring, its to show the items I hate the most about the CMStacker Case.

- The drive bay blanks require a steak knife to remove.

- The tooless drive retention stuff has too much play and needs to go.

- Primer gray is as bad as beige and needs to go.

- My cat left permanent white paw marks on the top when she knocked over a fish bowl and walked across the bare metal top.

- I hate the plastic cap on the top-front.

- I hate the stock front panel thingy with the power button and USB ports.

- The top blow hole blows no air.

- No matter how much someone mods a CMStacker case, it ends up looking just like a modded CMStacker case.

Now for the new components.

- Mobo: EVGA 122-CK-NF68-A1 680i ATX

- CPU: Intel Core 2 Duo E6600 Conroe 2.4GHz

- RAM: CORSAIR Dominator (2 x 1GB) DDR2 1066

- GPU: EVGA 8800GTS 640MB Superclocked

- PSU: Silverstone ST85ZF

Sadly, the case is not done (its not even started), and i cannot wait to start tasting the raw power of my new computer. Plus i need to test for DOA stuff. So where does one place $1600 worth of computer guts while waiting for the new case to be completed.....

In a computer case found at the dump of course.

Goodbye 400Mhz, hello 3Ghz!

Cool things you learn every time you rebuild a PC.

Like applying bird-turd' (AS5) is that you want to wipe it around on the heat sink and CPU then gently wipe it off. This fills the pitts. Then you apply a thin line across both cores and let the heat sink spread it with even pressure. I think I added too thick of a bead, Ill redo it when the water cooling stuff is installed.

Comments? Suggestions?

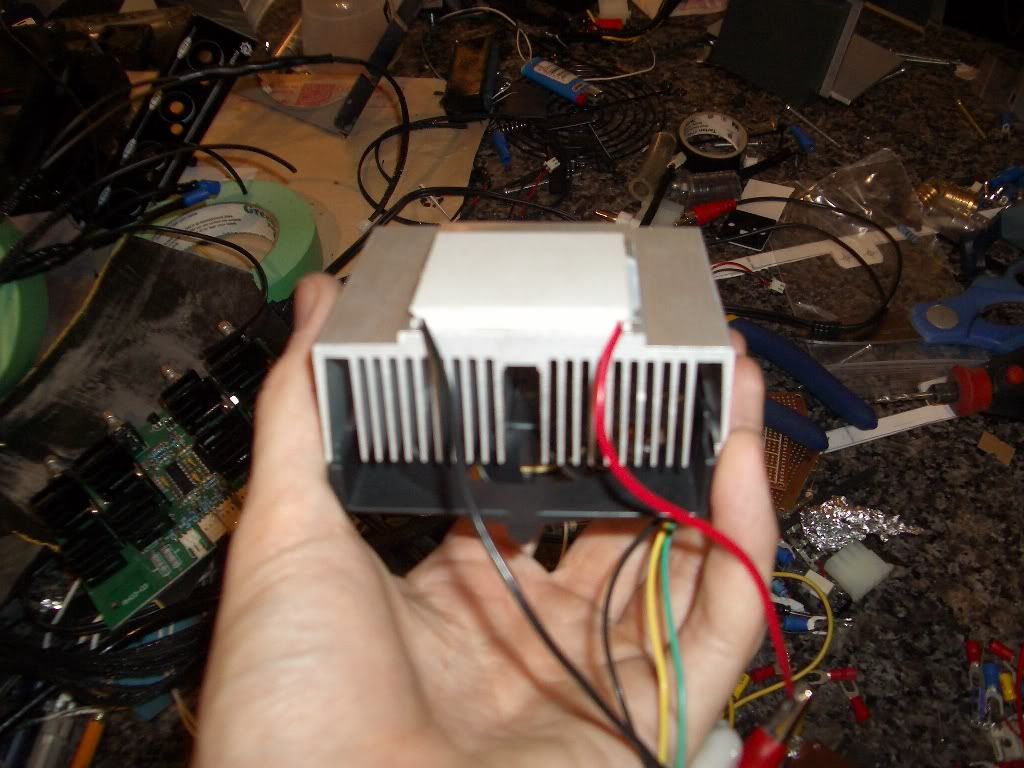

PSU Checks out.

Man these things are bigger in real life!

I feel so ashamed! This will be my inspiration to work fast to complete this mod on time.

Now onto the stuff you've been waiting for, the modding!

First things first is to tear apart the old PC.

All the way apart.

Completely Naked and ready for cutting.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)