This subject has come up lately so I thought I would start a new thread on it.

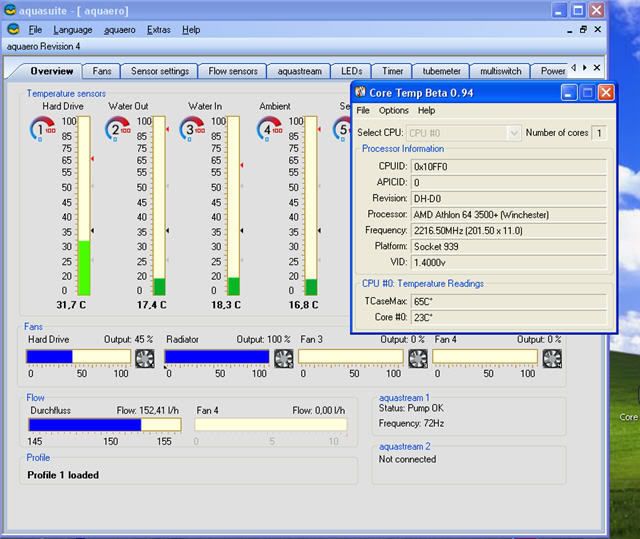

What I am trying to do is to ascertain the accuracy of my temp sensors I use in my Aquaero. I checked the AC website and they don't even list the tolerance of the sensors they sell (not a good sign). So what I want to know is if I measure the temp of the water right next to where the temp sensor is can I be reasonably sure that the temps are being reported correctly. I figured to go buy a Fluke 179 multi-meter because I want a good one (My analog Radio Shack MM died after 30 years service) and it also has a temp probe capability. The sensor I figured to get is the 80PK-22 Alternatively I also though of getting a lab grade mercury immersion thermometer and just sticking it in the reservoir through one of the top holes:

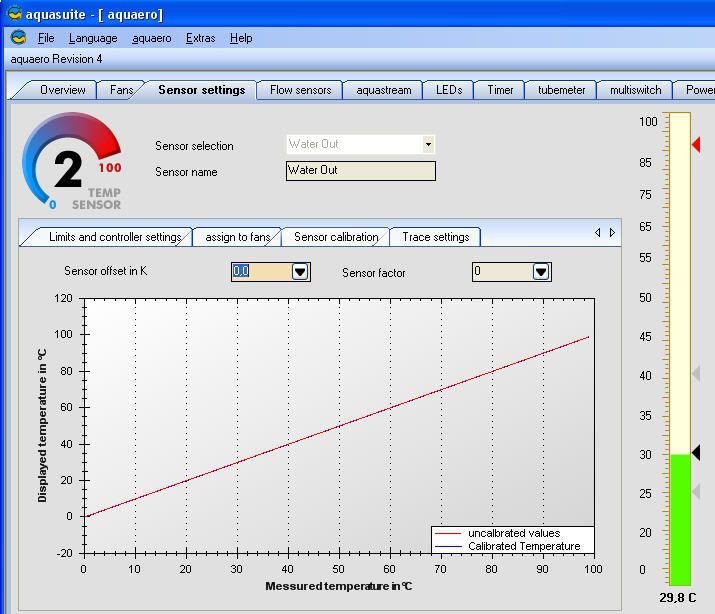

The Aquaero does allow me to make changes to the sensor settings to account for different sensors and I think this is the screen that does it:

So what is the best way to go about this? Is the Fluke overkill?

What I am trying to do is to ascertain the accuracy of my temp sensors I use in my Aquaero. I checked the AC website and they don't even list the tolerance of the sensors they sell (not a good sign). So what I want to know is if I measure the temp of the water right next to where the temp sensor is can I be reasonably sure that the temps are being reported correctly. I figured to go buy a Fluke 179 multi-meter because I want a good one (My analog Radio Shack MM died after 30 years service) and it also has a temp probe capability. The sensor I figured to get is the 80PK-22 Alternatively I also though of getting a lab grade mercury immersion thermometer and just sticking it in the reservoir through one of the top holes:

The Aquaero does allow me to make changes to the sensor settings to account for different sensors and I think this is the screen that does it:

So what is the best way to go about this? Is the Fluke overkill?

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)