Ultragamma

Weaksauce

- Joined

- Jan 28, 2005

- Messages

- 105

I have posted a thread before about me doing a DIY acrylic top for my DDC pump. I know many people already changed to the D5, but i still like my DDC and like to make the best performance out of it and make it look good too. I didn't gain the access to the CNC machine so everything on this is done on a table drill and table grinder with buffing wheels.

I went to many different version to get this right and perform the correct way. I will list the version below. Feel free to left comments, i just want to share my excitement as i complete everything. I was done a few weeks ago but never had the time until i came back from my business trip to malaysia.

Enough talk here are some pictures.

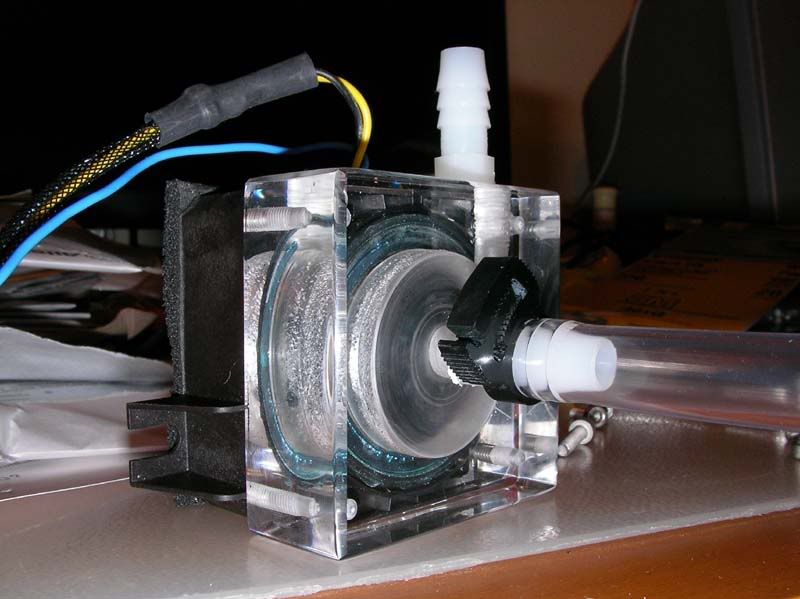

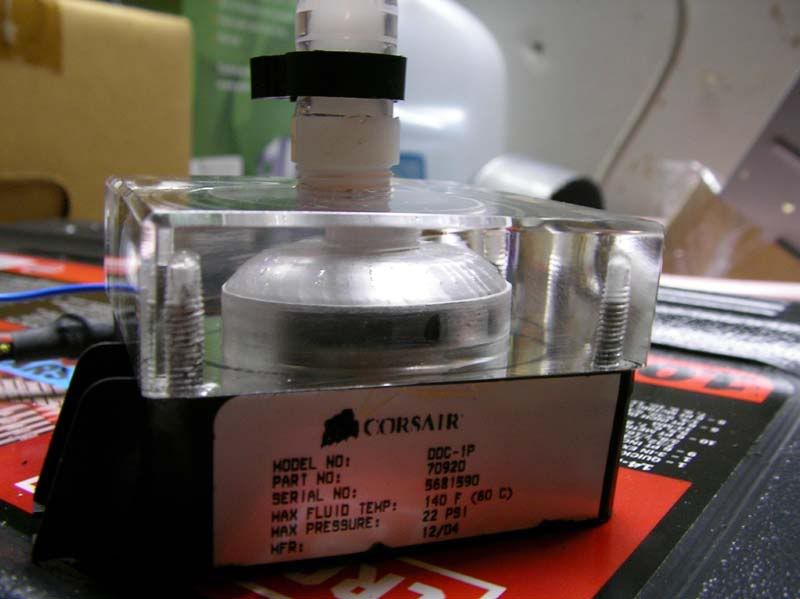

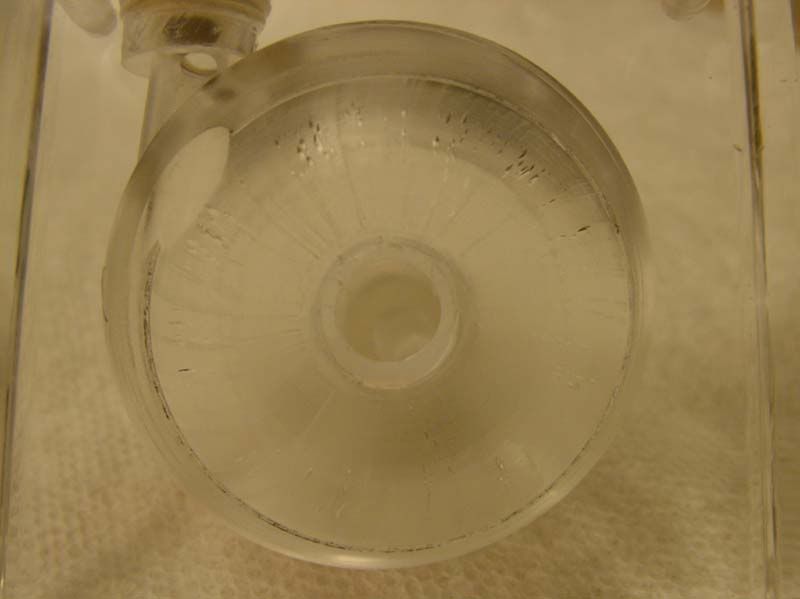

Here is the first version with 1/8 NPT Barbs. Later i found out that future upgrade to 1/2" barbs is nearly impossible for 1/8 NPT so i throw it out. Also the major defect is that the chamber is too deep and square that the output is actually decreased from the original top.

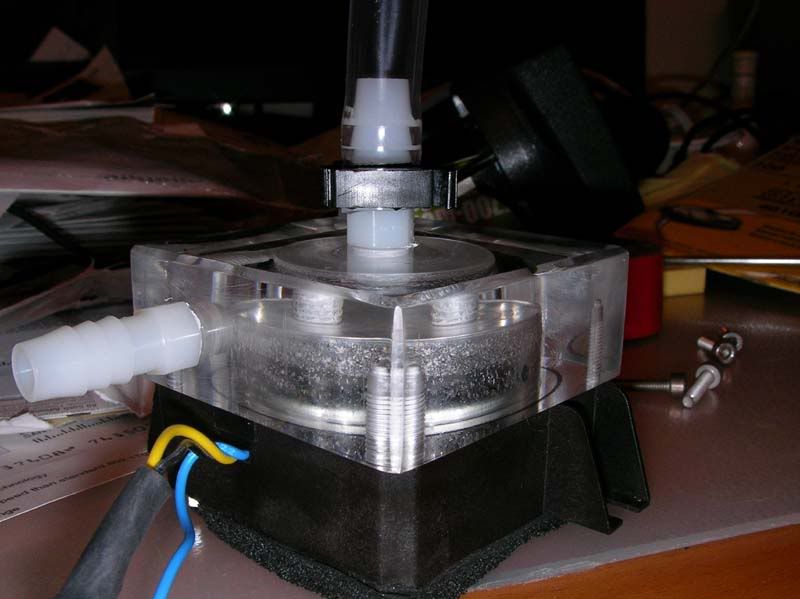

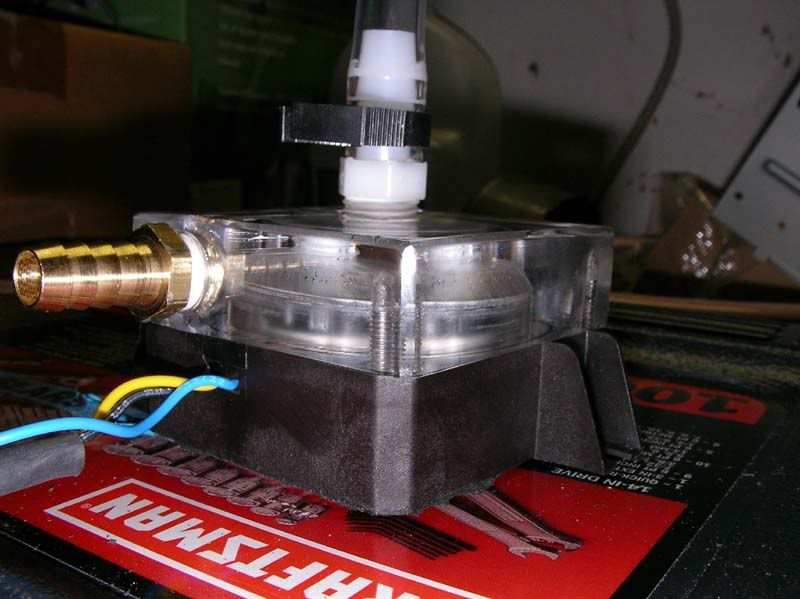

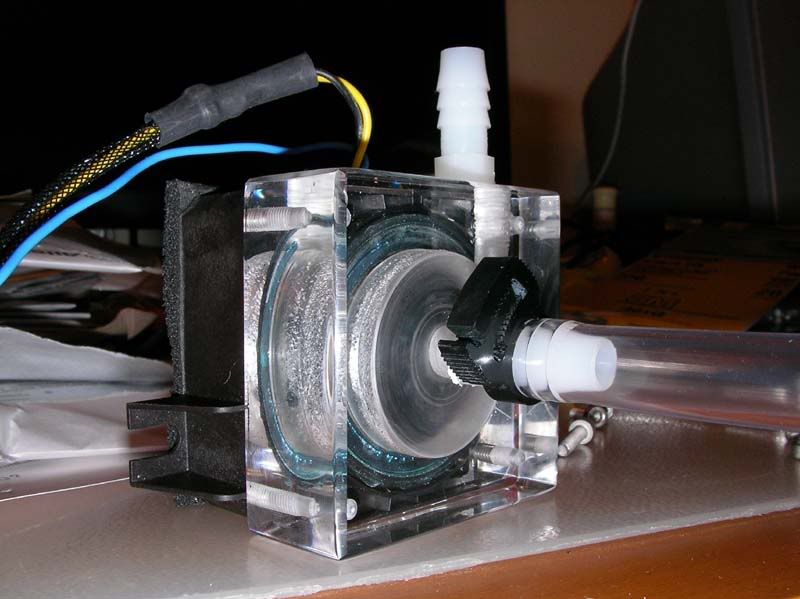

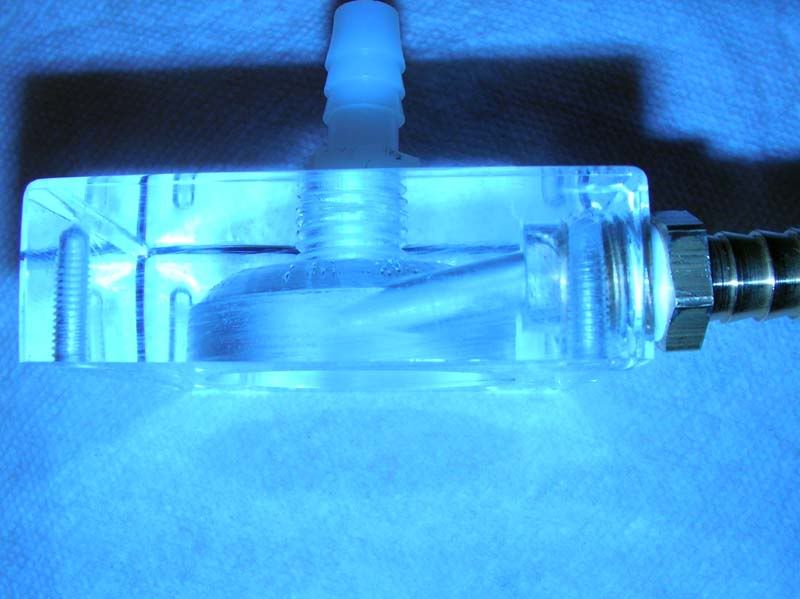

So here are some pictures for the 2nd Version before final buff on the side.

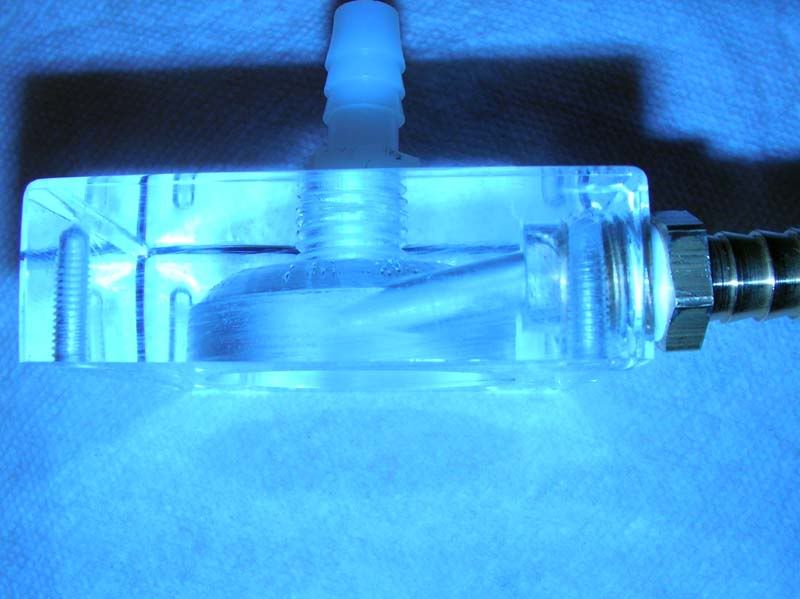

with blue light

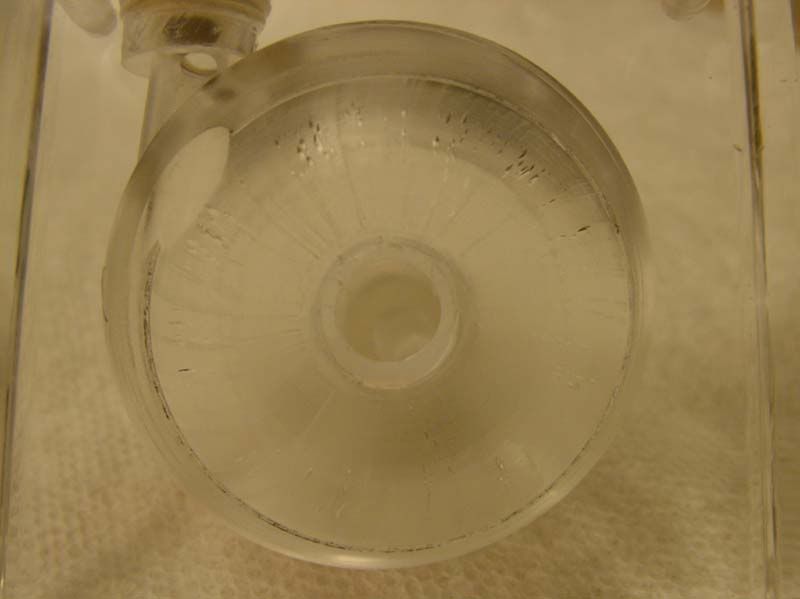

This version is more improve version. It uses 1/4 NPT barbs, so it is possible to use 1/2" barbs for 1/2" or 7/16" tubings in the future.

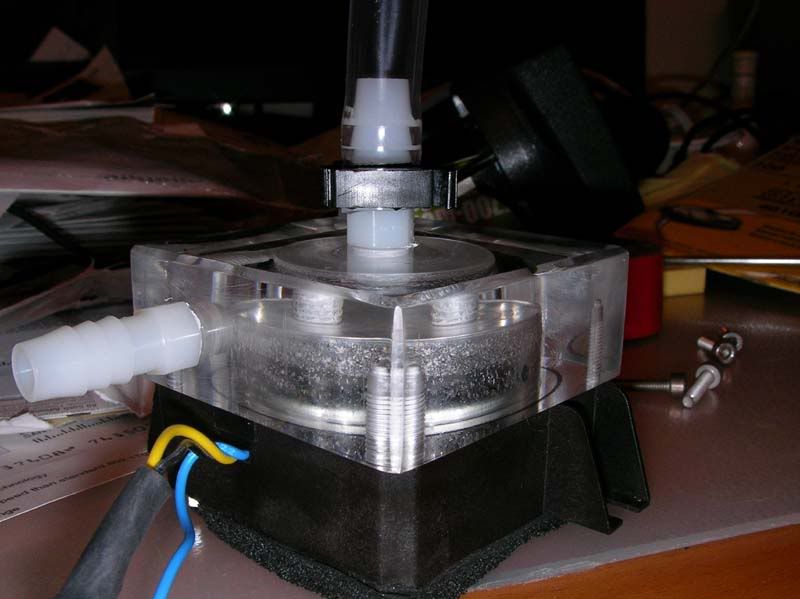

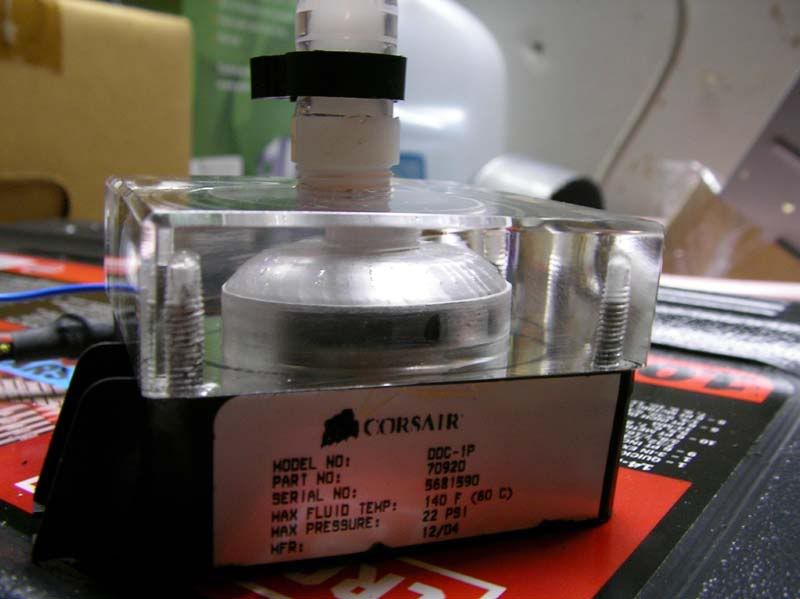

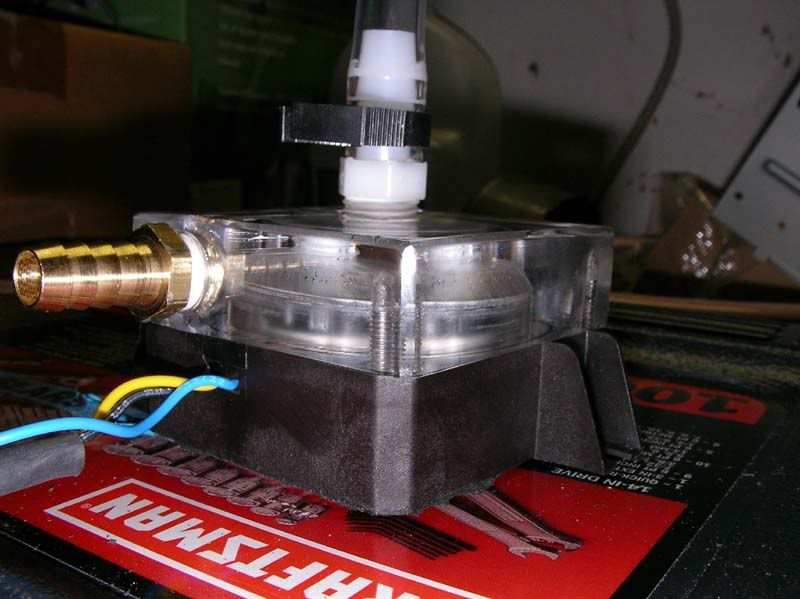

Finally, the finish product.

I had to use bronze fitting because the nylon barbs get cut-up by the sharp threads on the acrylic.

I went to many different version to get this right and perform the correct way. I will list the version below. Feel free to left comments, i just want to share my excitement as i complete everything. I was done a few weeks ago but never had the time until i came back from my business trip to malaysia.

Enough talk here are some pictures.

Here is the first version with 1/8 NPT Barbs. Later i found out that future upgrade to 1/2" barbs is nearly impossible for 1/8 NPT so i throw it out. Also the major defect is that the chamber is too deep and square that the output is actually decreased from the original top.

So here are some pictures for the 2nd Version before final buff on the side.

with blue light

This version is more improve version. It uses 1/4 NPT barbs, so it is possible to use 1/2" barbs for 1/2" or 7/16" tubings in the future.

Finally, the finish product.

I had to use bronze fitting because the nylon barbs get cut-up by the sharp threads on the acrylic.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)