lillimon04

2[H]4U

- Joined

- Oct 24, 2006

- Messages

- 3,770

MOAR!!!!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Yea - im on many forums and am a mod on overclock.net even....

whats another

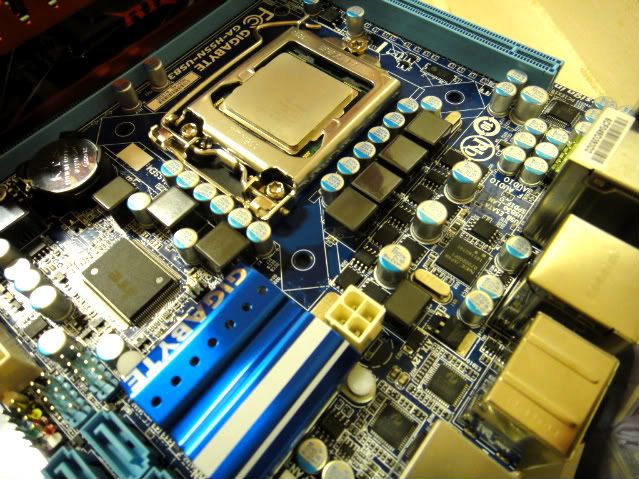

i still have a little work to do on mine - window and need to get some of those enzotech heatsinks onto the mosfets on the underside of my mobo - done the ones on the top.

My problem is that the H50 backplate covers them - so i will have to cut out one side of the backplate - anyone see a problem with that?

I'll keep an eye on this thread too - if your on any other forums i can give yo ua link to my worklog also (ocn, ocau, i4memory, overclockerstech, are my most visited sites)

Also - what sort of overclock you got/expecting out of your cpu

im running the i7 860 so i have a lot more load on my mobo so im not expecting any major overclocking unlike in the past (Q6600 @ 50% 24/7 etc in the past)

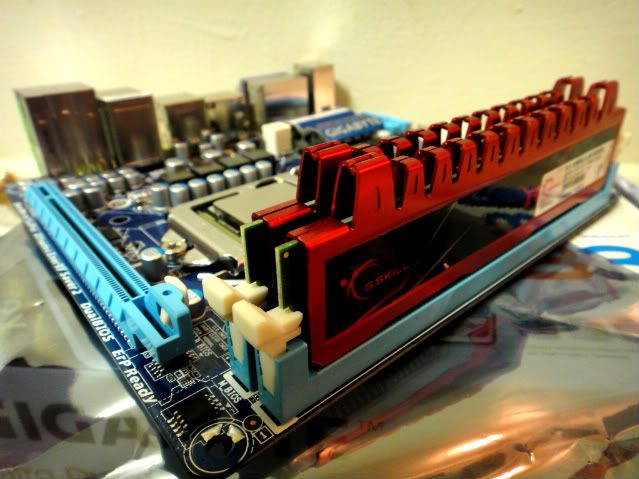

ATM - the only thing thats not running stock is my ram - its at 1333 cas 6 (stock is 2000mhz cas 9 - aka overkill but i got them cheap)

hmm - where you find that figure of 3.4?

my 860 is alot more load than a 750, so i was thinking anything > 3.2ghz would be bonus for mine

3.6ghz would be nice

ive read that thread through a few times in the past....

i believe that the 2 boards have a similar mosfet setup - bu the DFI has digital ones (so slightly better quality)

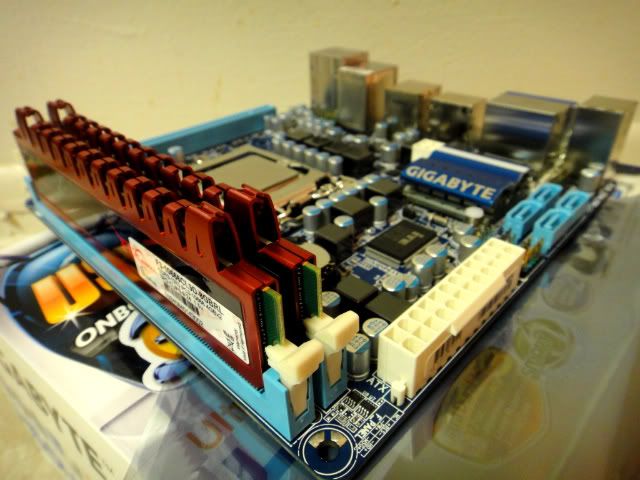

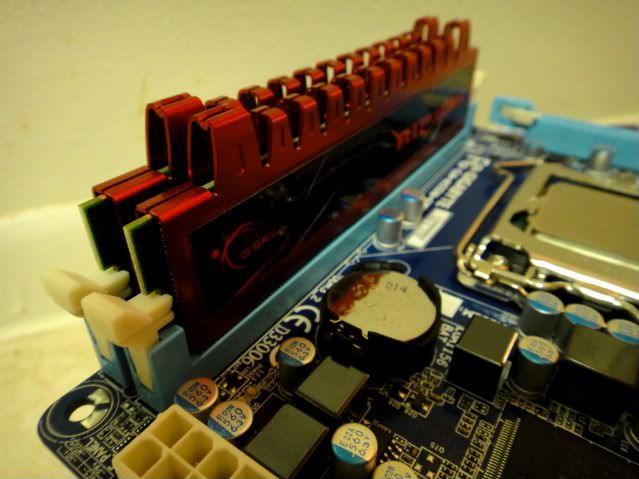

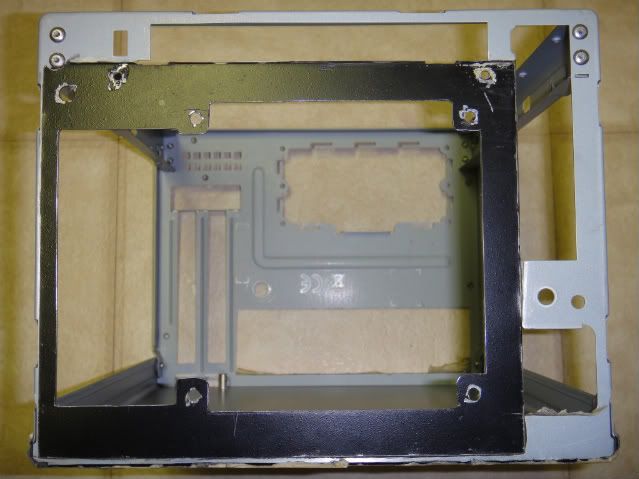

i got some mosfet heatsinks - enzotech MOS-C1's

have installed them onto the top mosfets - but the rear ones will be interesting....

1) they are too tall - need to trim them a bit

2) the H50 backplate half covers them - so will have to hack it up - that should be fine somewhat still yea?

3) the HD5850 is having all sorts of issues - so i think i'll rma it also.

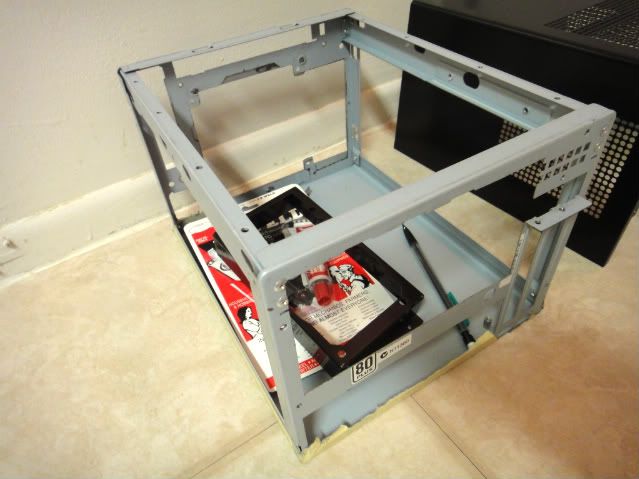

Also - i was thinking of using my dead HD4870s fan for some motherboard cooling - to get some air circulating under the mobo - but to do this i will need to trim the fined part of the fan to make it fit under the fan on the H50 - if i cut them all to the same size - the weight distribution should still be fine nad thus shouldnt affect the fan should it?

still waiting on the fan controller also.

bending them should prove to be hard also....

you have a pic of yours mounted?

the backplate looks to be just a thing to screw into - vs like the metal backplate of my TRUE which provides a bracing point for the TRUE's weight.

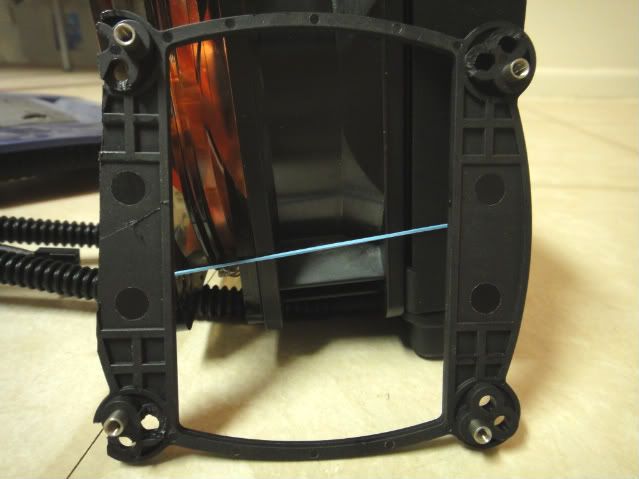

my H50 is set as exhaust - goes:

Front < H50 Rad < 120*25mm shroud < 120*38mm fan

this setup works - but its still la little loud as the 24pin fan goes right across the fans intake - infact the clip on the 24pin connector is touching the fan.

i was going to use the 4870's fan as its a squirrelcage fan, such that it wont take up much room and most of its output will go under the mobo.

i would need to shorten the fins a little as they will spin partially under the fan on the H50 - the central hub of the fan is fine as it wont be under the h50s fan.

mines set to exhaust...

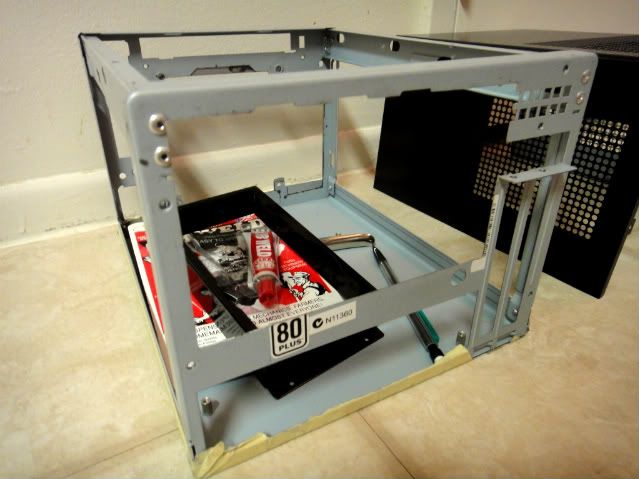

Using a Scythe Ultra Kaze 2k rpm + the 120*25mm shroud.

pretty sure the noise is coming form the air moving over the cable thats across the front of the fan (the 24pin)

My other fan options (that i have here):

Scythe Slipstream 110cfm version (120*25mm)

Older Nocta fan (2 series old or so i think) 120*25mm

Pair of Sunon 120*38mm fans (not using them - both are 130cfm +)

Coolermaster fans that come stock with RC690 (aka cm690)

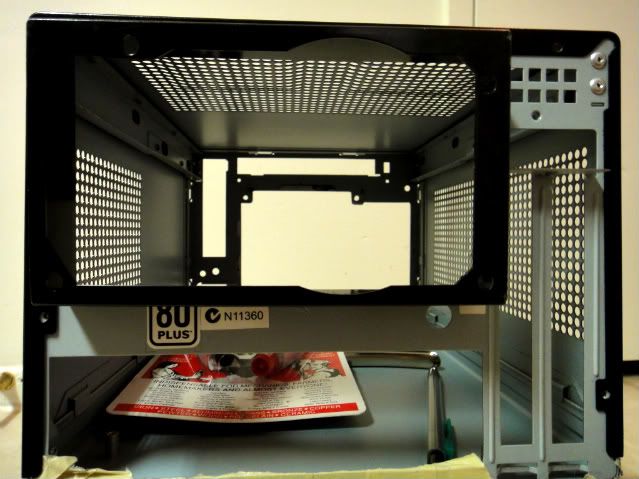

Lain li fans (stock ones i got with the Lian Li v2010b i have here)

Some generic (but *ok*) Blue LED 120*25mm fans

unplugging the front fan makes my system almost dead silent (except the HD5850s fan when playing games)

I might look at changing the fan (again) then

can you link where you found that PSU extender ?