officermartinez

[H]ard|Gawd

- Joined

- Jan 21, 2006

- Messages

- 2,012

This is the start of a new project for me. This is my first time, stepping into the world of phase change. So, as a result, I will do my best to keep my Vapochill experience as easy as possible. Understandably, there are several mods that a Vapochill owner can do. For purposes of this project, I intend to keep the Vapochill LightSpeed stock (it's under warranty).

Let me run through to a list of items that I intend to use during my build. This list is not all inclusive as I may or may not list every single screw, bolt, washer, etc. However, with that said, I will do my best to document my work.

1. Vapochill LightSpeed Unit.

2. Lian Li PC-7A.

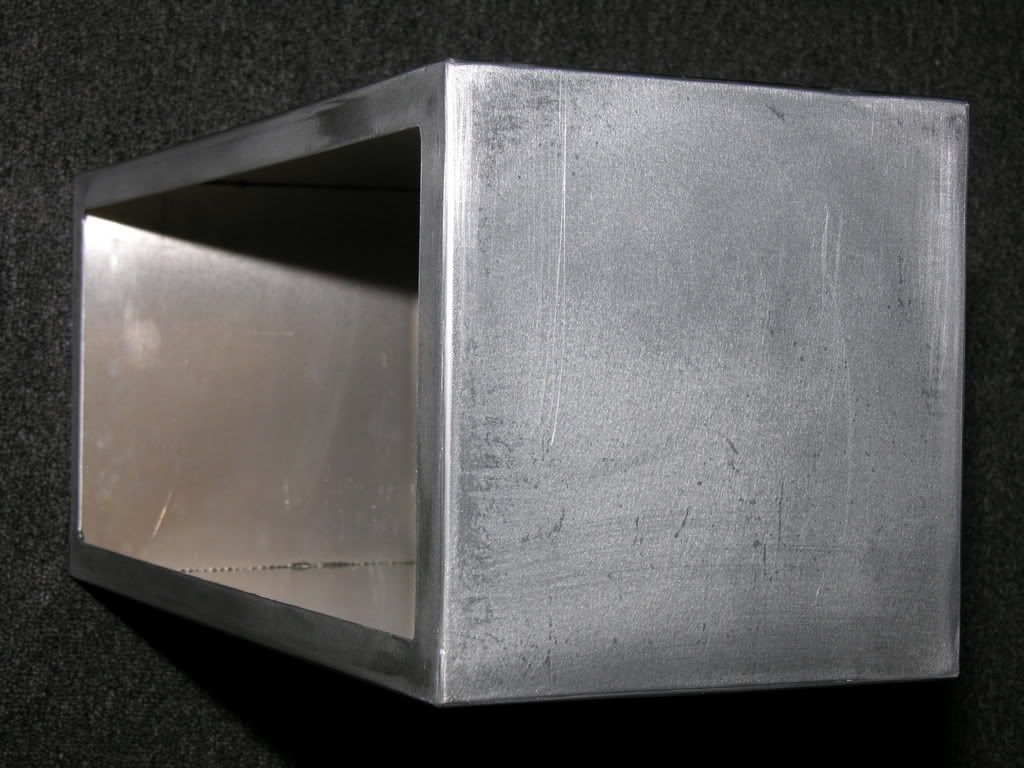

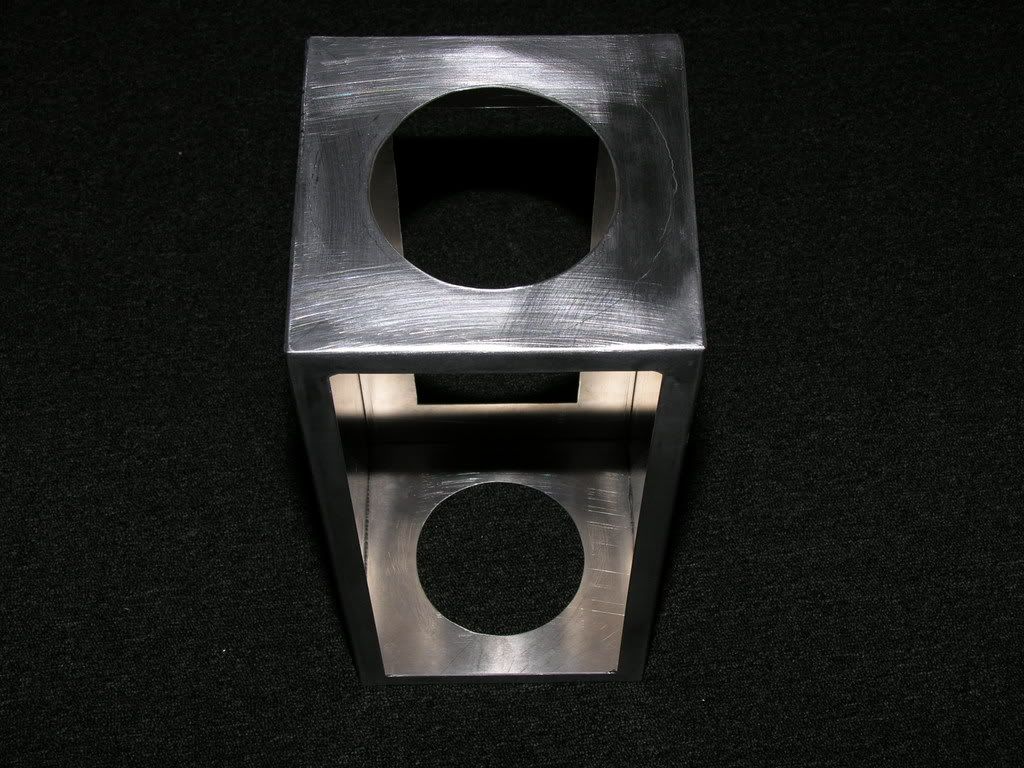

3. A radiator box that was designed from my specs at a local CAD shop.

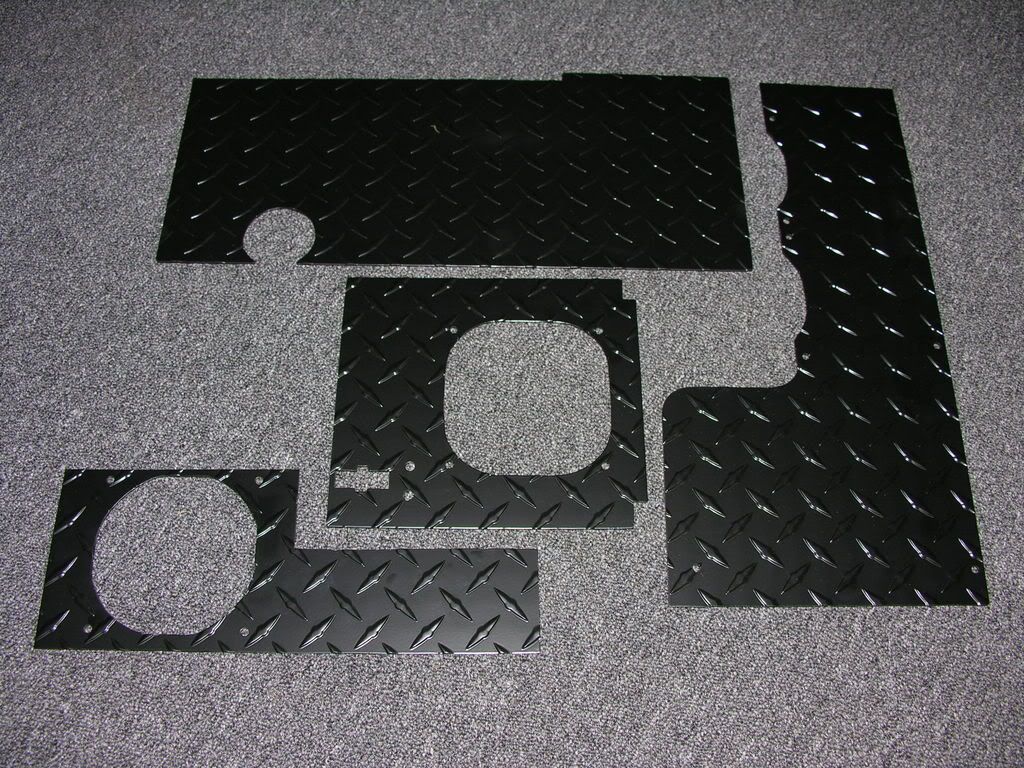

4. Scrap Lian Li aluminum (purchased from Performance-PC's).

5. Diamond Plate aluminum (purchased from my local Home Depot).

6. Various screws, bolts, nuts, washers and trimming.

7. An A.C. Ryan 3x120mm radiator grill.

8. (3) 5" speaker box bass ports.

The components that I have chosen for this installation are listed below:

1. QX6700 quadcore processor

2. XFX 680i LT motherboard

3. (4) gigabytes of Corsair Dominator Ram - DDR2-1066 (8500C5D)

4. (2) eVGA 8800GTS 640mb video cards (in SLi)

5. Enermax Galaxy 1000w PSU

6. Seagate Barracuda 7200.10 / 500gb HDD

7. Samsung CD/DVD-RW drive (model SH-S182)

8. Pro-Gear XM-4U card reader

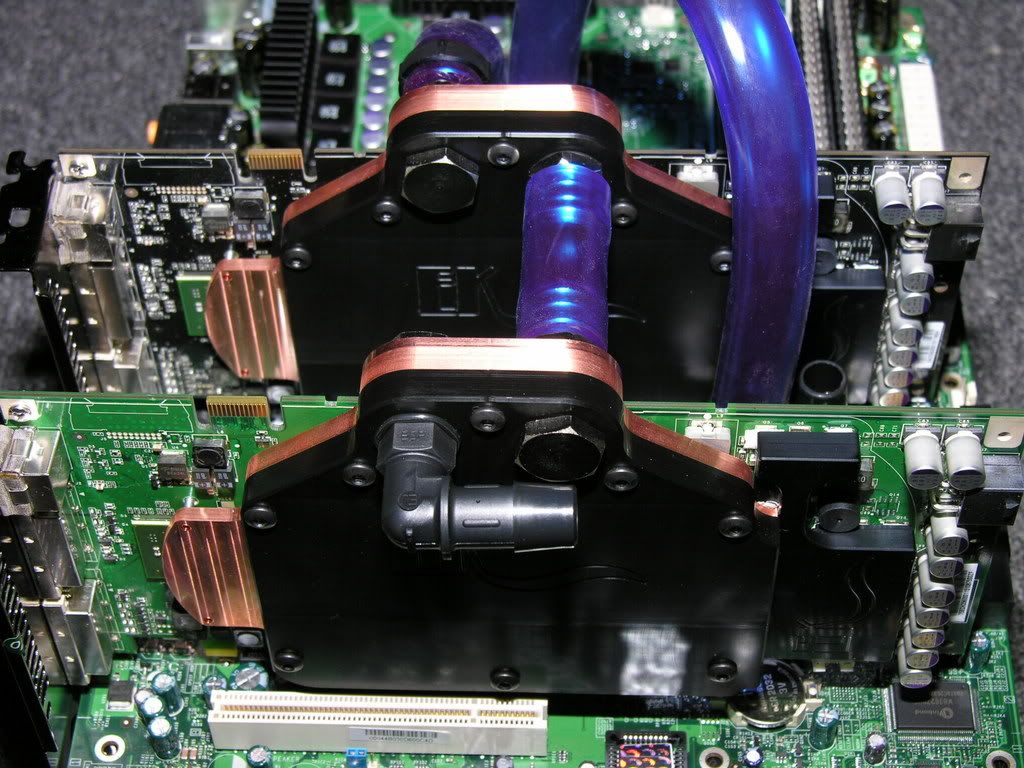

9. Swiftech MCP655 water pump

10. Triple 120mm radiator

11. EK reservoir (model EK-RES-150)

12. Swiftech MCW30 waterblocks x 2 for my NB and SB chipsets

13. EK waterblocks x 2 for my 8800GTS video cards (model EK-FC8800GTS-ACETAL)

14. (7) Aerocool 89cfm 120mm Blue LED fans

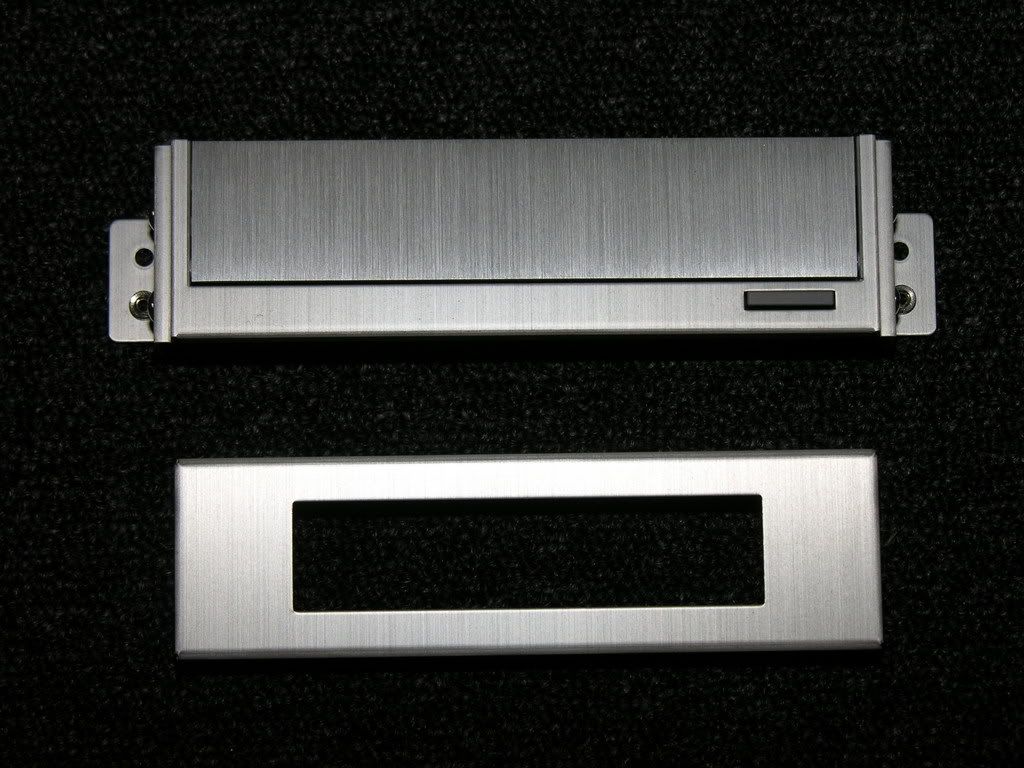

15. Lian Li CD-ROM bezel

16. Lian Li 5 1/4" to 3 1/2" bay converter.

17. Sunbeam (4) switch fan controller

18. Luxurae HDSS Silent Hard Drive Mount

Services that were performed by someone other than me:

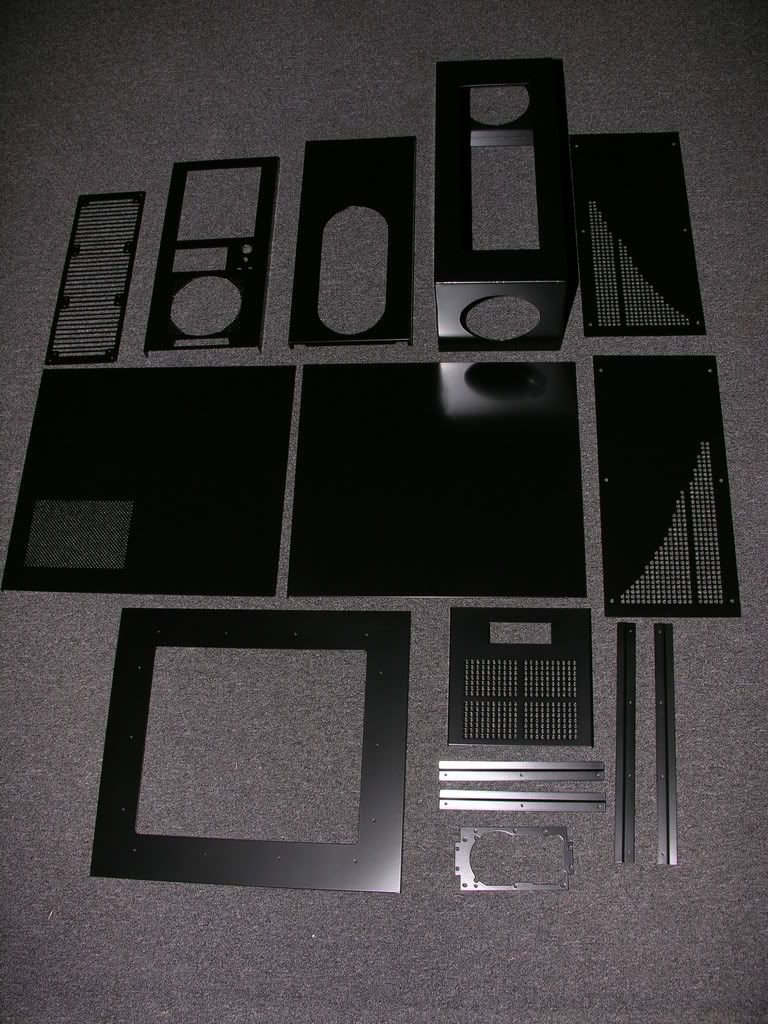

Fabrications LTD in Haltom City, Texas. From a 17 ton press to delicate CAD work, this company really helped me achieve a nice finished product.

Top Koat Powder Coating in Kennedale, Texas. The new owner, Joe, really takes his job seriously. The finished product is always perfect. I use his services ALOT!

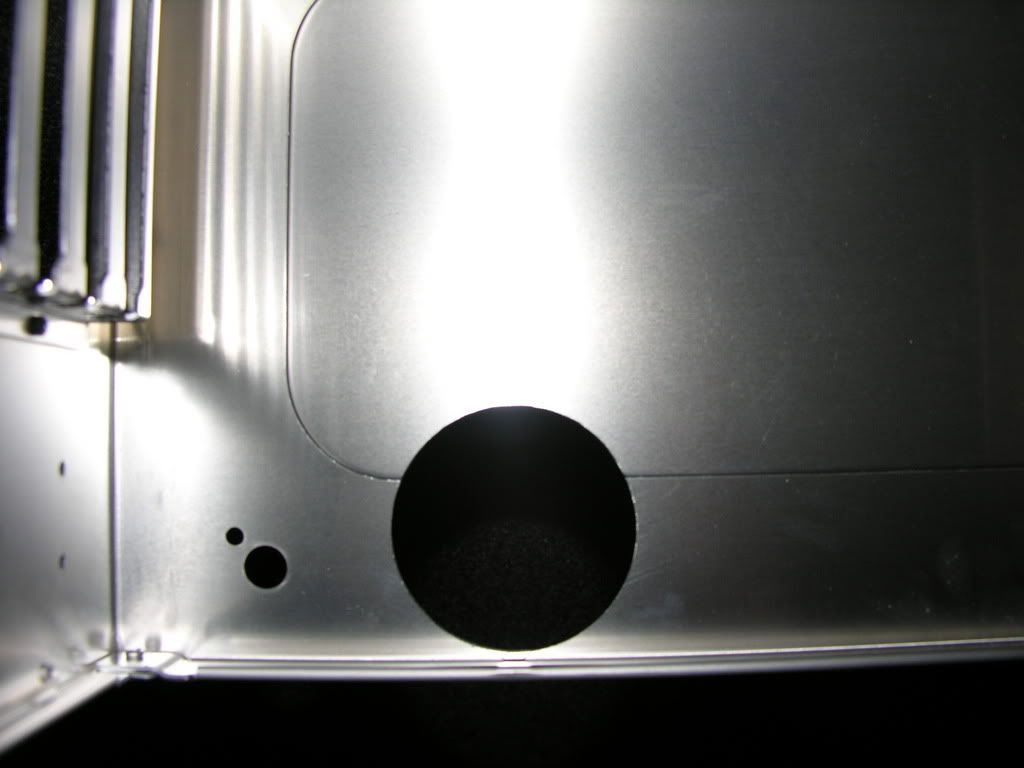

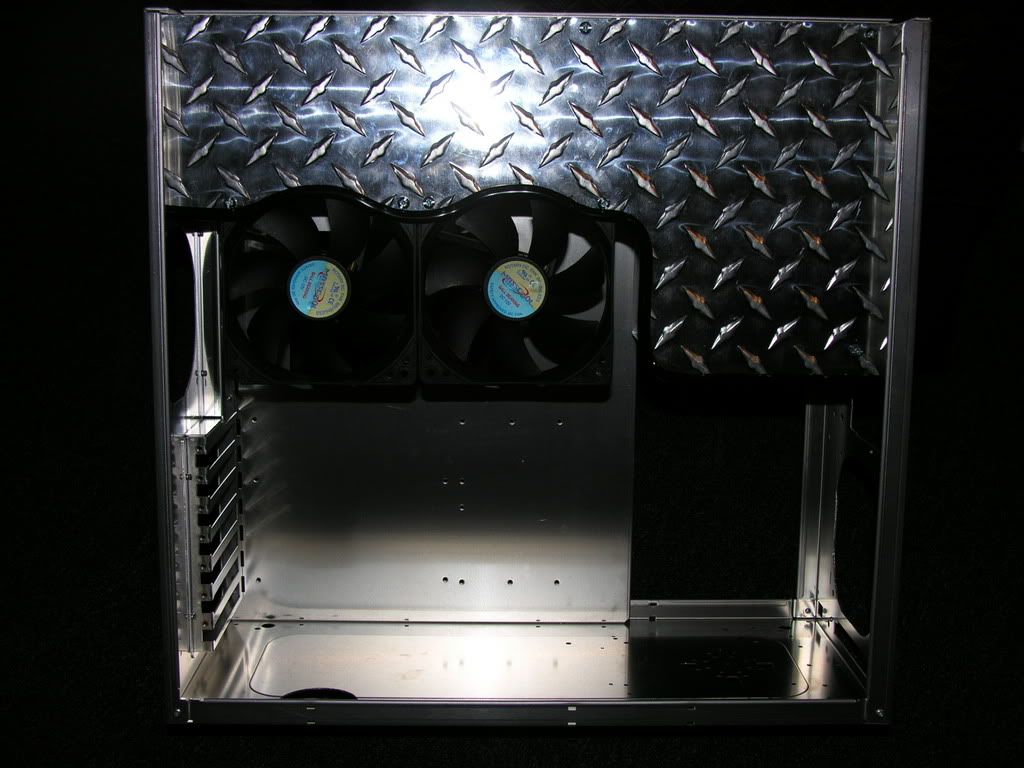

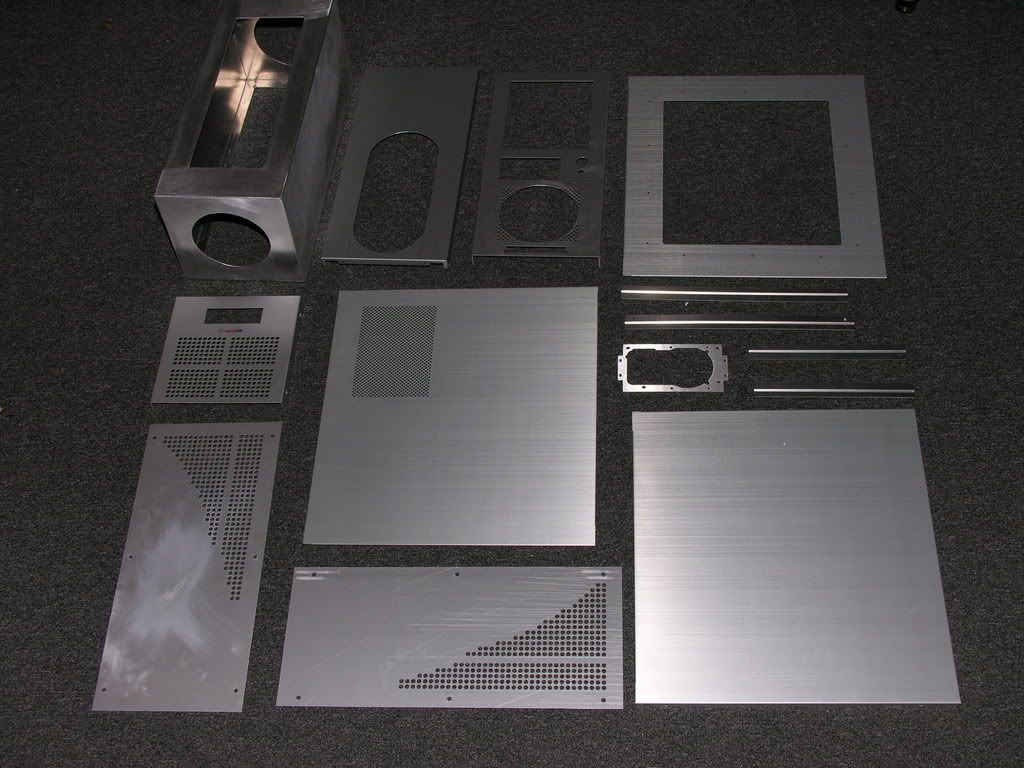

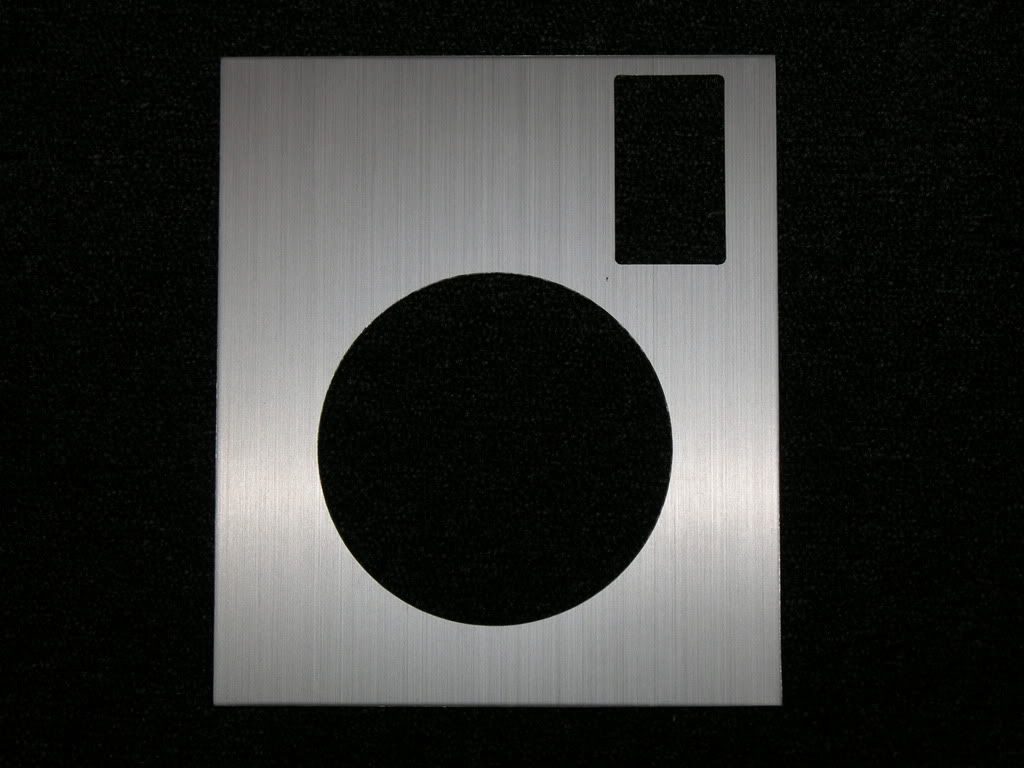

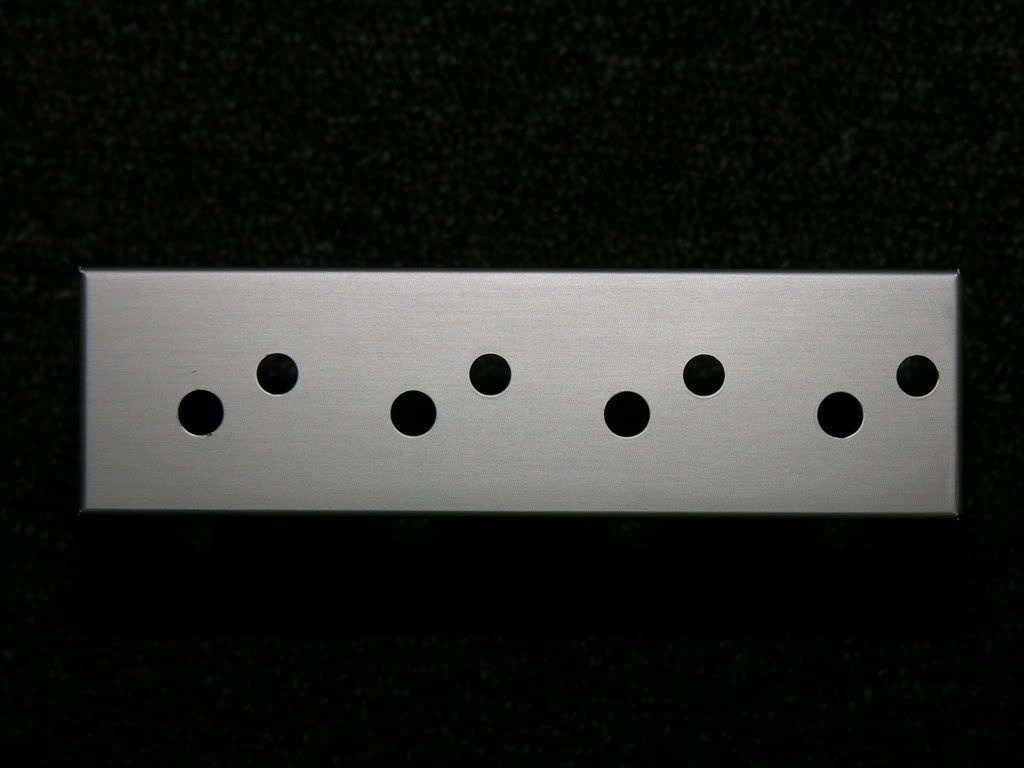

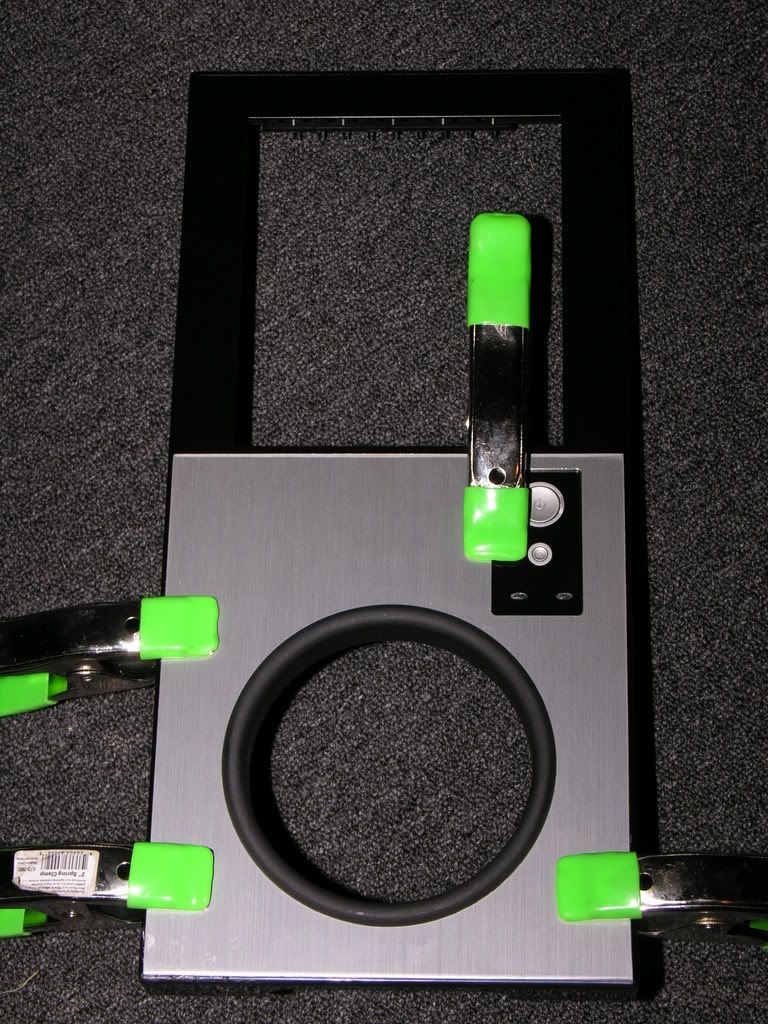

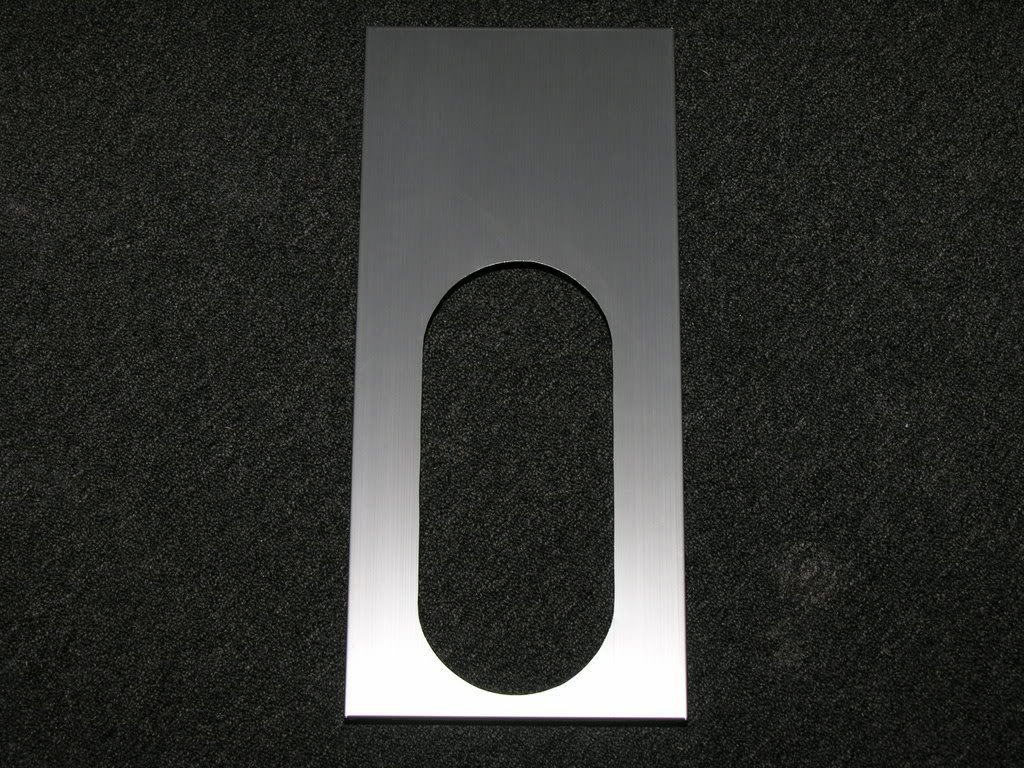

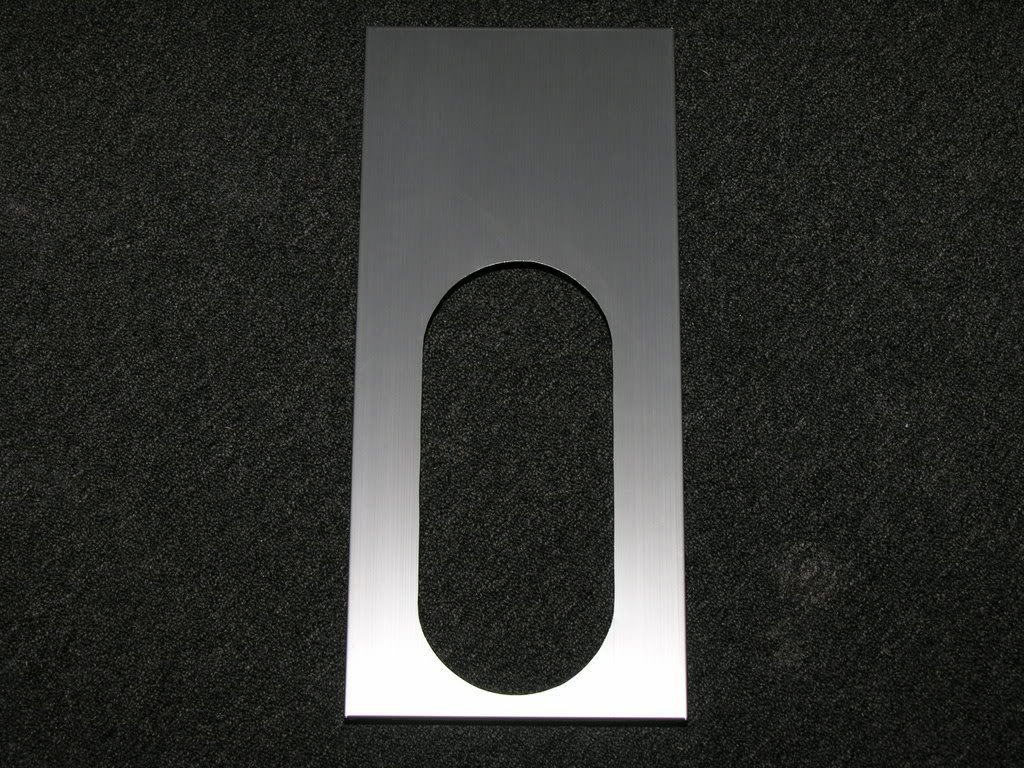

Let's start. I purchased a Lian Li PC-7A. It is completely silver (aluminum). It makes for a very nice mid-sized case. At the time of purchase, I thought to myself that a nice see though window would compliment the interior of my build. So, for a little more than $25 dollars, I bought the optional see through side panel. Nice and pretty. Since I knew from the very beginning, I would need to purchase the Lian Li CDROM bezel (for that clean look), a 5 1/4" bay HDD mount and a bay converter for my card reader. In less than a week, my supplies came in. After inspecting things over, within 30 minutes of my parts arriving, I was already measuring, removing everything out of the case, taping things off, drilling out rivets and prepping for my first cut with my jigsaw.

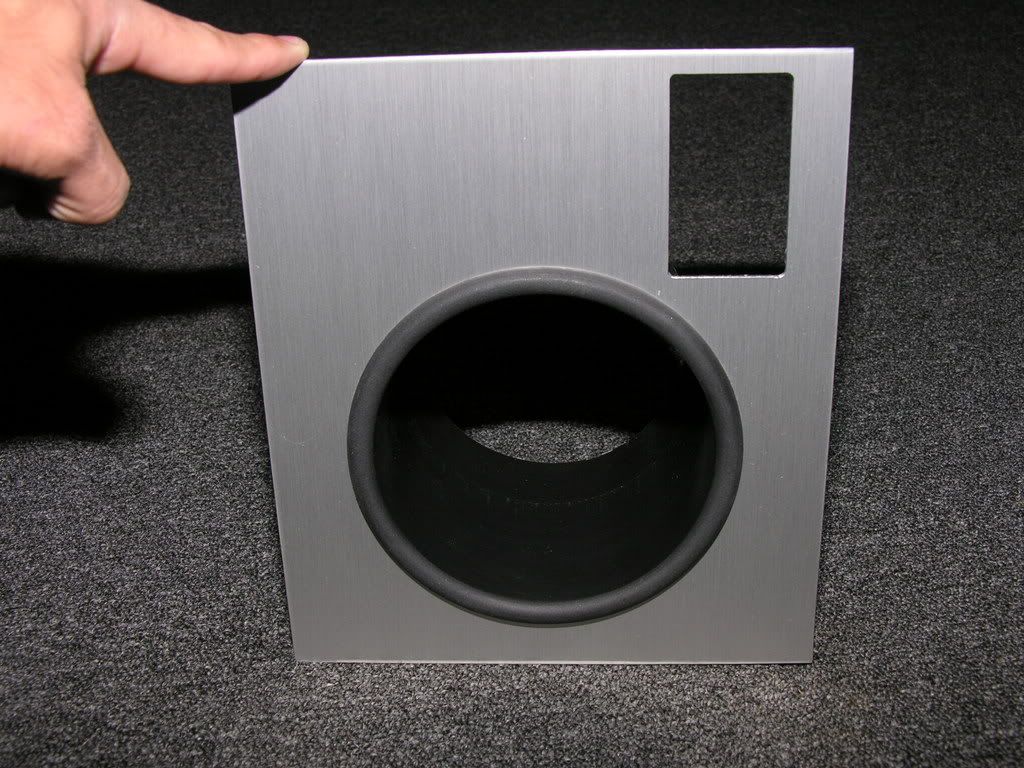

First, I drilled out the rivets which allowed me to remove the top portion of my Lian Li case. Once the rivets were removed, I measured my cuts twice, taped off the top of the case, and began cutting.

I then removed the 3M tape and after a little file work, here is the finished product:

Let me run through to a list of items that I intend to use during my build. This list is not all inclusive as I may or may not list every single screw, bolt, washer, etc. However, with that said, I will do my best to document my work.

1. Vapochill LightSpeed Unit.

2. Lian Li PC-7A.

3. A radiator box that was designed from my specs at a local CAD shop.

4. Scrap Lian Li aluminum (purchased from Performance-PC's).

5. Diamond Plate aluminum (purchased from my local Home Depot).

6. Various screws, bolts, nuts, washers and trimming.

7. An A.C. Ryan 3x120mm radiator grill.

8. (3) 5" speaker box bass ports.

The components that I have chosen for this installation are listed below:

1. QX6700 quadcore processor

2. XFX 680i LT motherboard

3. (4) gigabytes of Corsair Dominator Ram - DDR2-1066 (8500C5D)

4. (2) eVGA 8800GTS 640mb video cards (in SLi)

5. Enermax Galaxy 1000w PSU

6. Seagate Barracuda 7200.10 / 500gb HDD

7. Samsung CD/DVD-RW drive (model SH-S182)

8. Pro-Gear XM-4U card reader

9. Swiftech MCP655 water pump

10. Triple 120mm radiator

11. EK reservoir (model EK-RES-150)

12. Swiftech MCW30 waterblocks x 2 for my NB and SB chipsets

13. EK waterblocks x 2 for my 8800GTS video cards (model EK-FC8800GTS-ACETAL)

14. (7) Aerocool 89cfm 120mm Blue LED fans

15. Lian Li CD-ROM bezel

16. Lian Li 5 1/4" to 3 1/2" bay converter.

17. Sunbeam (4) switch fan controller

18. Luxurae HDSS Silent Hard Drive Mount

Services that were performed by someone other than me:

Fabrications LTD in Haltom City, Texas. From a 17 ton press to delicate CAD work, this company really helped me achieve a nice finished product.

Top Koat Powder Coating in Kennedale, Texas. The new owner, Joe, really takes his job seriously. The finished product is always perfect. I use his services ALOT!

Let's start. I purchased a Lian Li PC-7A. It is completely silver (aluminum). It makes for a very nice mid-sized case. At the time of purchase, I thought to myself that a nice see though window would compliment the interior of my build. So, for a little more than $25 dollars, I bought the optional see through side panel. Nice and pretty. Since I knew from the very beginning, I would need to purchase the Lian Li CDROM bezel (for that clean look), a 5 1/4" bay HDD mount and a bay converter for my card reader. In less than a week, my supplies came in. After inspecting things over, within 30 minutes of my parts arriving, I was already measuring, removing everything out of the case, taping things off, drilling out rivets and prepping for my first cut with my jigsaw.

First, I drilled out the rivets which allowed me to remove the top portion of my Lian Li case. Once the rivets were removed, I measured my cuts twice, taped off the top of the case, and began cutting.

I then removed the 3M tape and after a little file work, here is the finished product:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)