ohh man...i have seen your other case before. i was inspired after seeing it. i planned out my wooden case (no where near as good as yours) but i ever had the time...or energy to finish it. from the picture before the microwave you didn;t look that old. but the skills you have makes me think twice about your age

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project: Yuugou

- Thread starter greensabbath

- Start date

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

ipam45 said:ohh man...i have seen your other case before. i was inspired after seeing it. i planned out my wooden case (no where near as good as yours) but i ever had the time...or energy to finish it. from the picture before the microwave you didn;t look that old. but the skills you have makes me think twice about your age

Thanks a lot man, I'm 20 and i still have much to learn about wood working. There are some people who are eons better than i am and i hope to be on their level in the future.

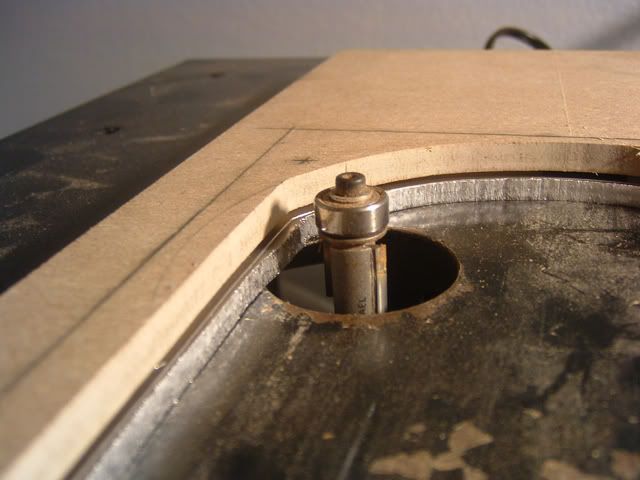

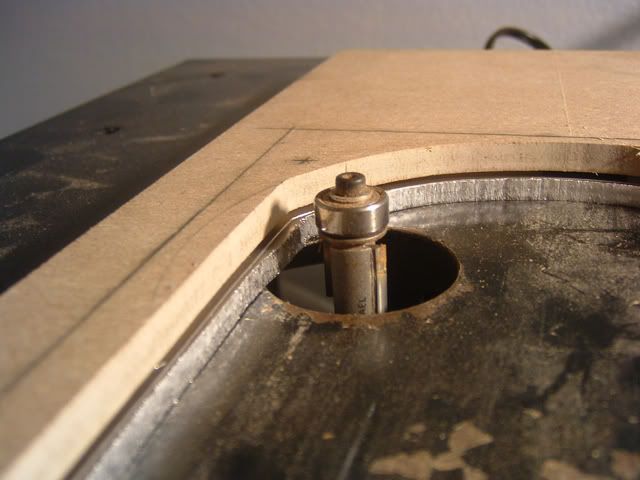

Before I can finish the wood i needed to do one last groove along the top panel of the case. To do this of course, i needed a new router bit.. this guy:

My CMT router bit family:

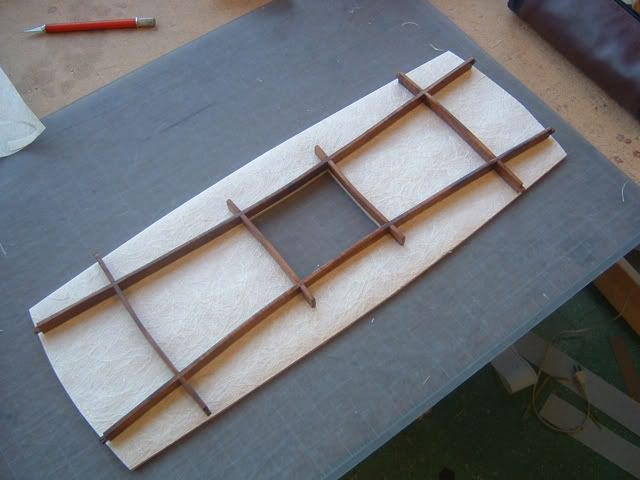

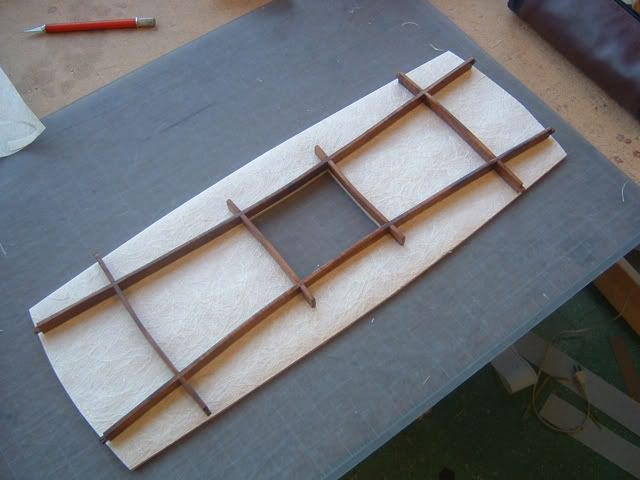

I forgot to take pictures of the progress on the top but i added the inner peices, sanded all of the wood and put one coat of finish on this koa part:

Everything waiting for finishing:

The big koa with a first coat:

Everything with a coat of finish:

A teaser of the finial finished side panel:

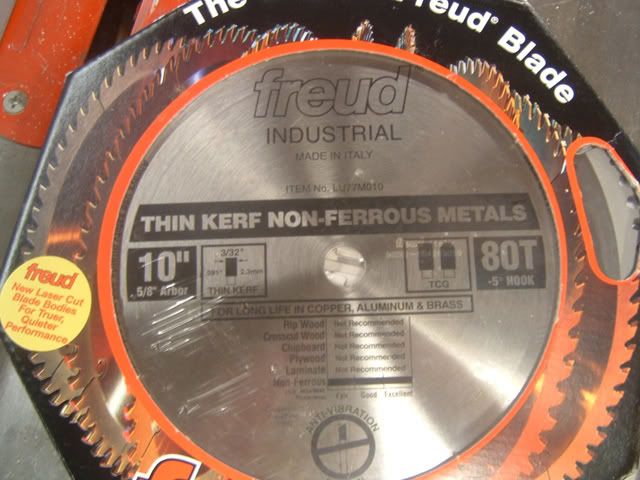

I bought a non-ferrous metal blade so i'll get the alu cut. My acrylic is coming on tuesday so i'm going to get the windows done this week too. I also need to route the grooves bigger for the front and back panel...not sure if i'm doing the koa front yet but we'll see. More to come in a bit, stay tuned.

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

I decided to experiement with the veneer today. First off, my new blade came:

And the players are:

Wood and Alu (this is oak veneer)

And Polyurethane glue:

The first step is to wet down the veneer since this glue likes moisture:

Then I spread the glue:

And then I clamped it between two cauls:

When it came out, it was pretty messy so after a bit of sanding, it looks like this:

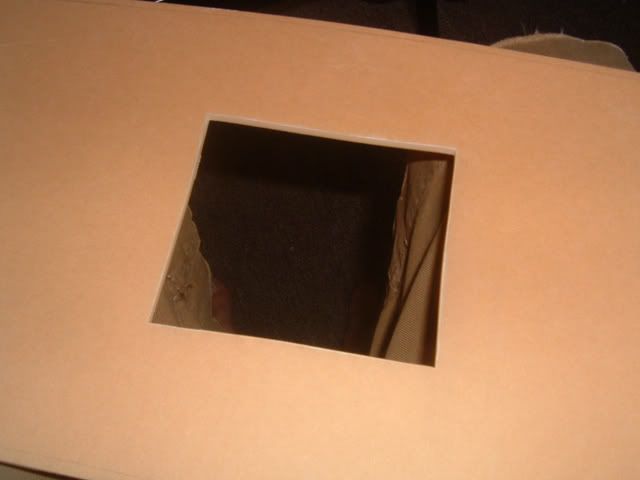

My acrylic also came and i cut one of the windows yesterday, this one happens to be the translucent ivory (with the paper still on)

and a teaser of what the whole thing will look like:

Today i'll finish the other acrylic panels and cut the paper hopefully. This acrylic was really really nice to work with. I got it from delviesplastics.com and i highly recommend them.

Lots of pictures in this update so here goes.

to attach the plexi to the wood, i decided to use this little setup: threaded aluminum spacers and black socket screws

and it went pretty well

I used the same polyurethane glue to glue the spacers in

The finished panel:

I wanted to put everything together to get the measurements for the aluminum that i need to cut before i leave for college again.

Putting it together:

Standing it up:

Putting in the front and back alu panels and setting the top on:

The wood is almost done...just barely..the outside wood i mean. I have to do the alu pretty quick and i'll have that in the next update. This is where everything needs to go:

I already did some work but i got really confused and stopped working. Suddenly i had to figure out where every single thing goes and how it goes together and i jsut got a headache instead. The hardest part to figure out is the lighting...ccfls again? or no lighting on the paper? i dunno. I'll keep working, stay tuned.

Next will be Aluminum

And the players are:

Wood and Alu (this is oak veneer)

And Polyurethane glue:

The first step is to wet down the veneer since this glue likes moisture:

Then I spread the glue:

And then I clamped it between two cauls:

When it came out, it was pretty messy so after a bit of sanding, it looks like this:

My acrylic also came and i cut one of the windows yesterday, this one happens to be the translucent ivory (with the paper still on)

and a teaser of what the whole thing will look like:

Today i'll finish the other acrylic panels and cut the paper hopefully. This acrylic was really really nice to work with. I got it from delviesplastics.com and i highly recommend them.

Lots of pictures in this update so here goes.

to attach the plexi to the wood, i decided to use this little setup: threaded aluminum spacers and black socket screws

and it went pretty well

I used the same polyurethane glue to glue the spacers in

The finished panel:

I wanted to put everything together to get the measurements for the aluminum that i need to cut before i leave for college again.

Putting it together:

Standing it up:

Putting in the front and back alu panels and setting the top on:

The wood is almost done...just barely..the outside wood i mean. I have to do the alu pretty quick and i'll have that in the next update. This is where everything needs to go:

I already did some work but i got really confused and stopped working. Suddenly i had to figure out where every single thing goes and how it goes together and i jsut got a headache instead. The hardest part to figure out is the lighting...ccfls again? or no lighting on the paper? i dunno. I'll keep working, stay tuned.

Next will be Aluminum

t_ski

Supreme [H]ardness

- Joined

- Jun 13, 2006

- Messages

- 7,506

Incredible. As an amatuer woodworker I love seeing those more skilled than I do fabulous things with their hands and tools.

I say you stay home from college and finish the rest up so we don't have to keep waiting!

I say you stay home from college and finish the rest up so we don't have to keep waiting!

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

Thanks very much guys, its always nice to see how many computer people are actually woodworkers too.

Everyone seems to post pics of their cats... but i only have dogs, so here ya go.

Jenny:

and Roxy:

Back to business. I've been working on the aluminum. First thing was the big panel:

Then the top:

Most of the aluminum will be held together by screws connected to 3/8 x 1/2inch aluminum peices like the one shown in the picture.

The middle shelf which will hold the tripple fan rad:

Another shot of the interior. Its starting to look like a nice big really really heavy aluminum box.

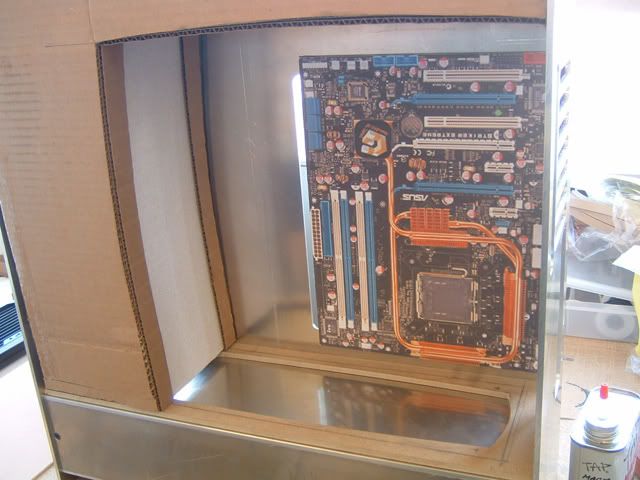

The next step is to figure out the inside. for this i turned to cardboard. My first scheme was this:

I really didn't like it though. The curve of the inside pieces made it seem really fat... no good.

So i tried this:

this seemed much better. I also tried it with a straight vertical piece:

Here are a couple more shots of the second design:

That's it for now and for a while most likely. I have to pack everything up and get ready to take it down to college. Once i get there I have to build a table to put it on while i work on it and get all my crap set up.

The next step is to cut some more aluminum parts for the main frame. Then i get to figure out the rest of the inside and where everything goes and I'll finally get to order some wcing parts. Until then, stay tuned.

Everyone seems to post pics of their cats... but i only have dogs, so here ya go.

Jenny:

and Roxy:

Back to business. I've been working on the aluminum. First thing was the big panel:

Then the top:

Most of the aluminum will be held together by screws connected to 3/8 x 1/2inch aluminum peices like the one shown in the picture.

The middle shelf which will hold the tripple fan rad:

Another shot of the interior. Its starting to look like a nice big really really heavy aluminum box.

The next step is to figure out the inside. for this i turned to cardboard. My first scheme was this:

I really didn't like it though. The curve of the inside pieces made it seem really fat... no good.

So i tried this:

this seemed much better. I also tried it with a straight vertical piece:

Here are a couple more shots of the second design:

That's it for now and for a while most likely. I have to pack everything up and get ready to take it down to college. Once i get there I have to build a table to put it on while i work on it and get all my crap set up.

The next step is to cut some more aluminum parts for the main frame. Then i get to figure out the rest of the inside and where everything goes and I'll finally get to order some wcing parts. Until then, stay tuned.

boostdemon

Limp Gawd

- Joined

- Nov 12, 2004

- Messages

- 147

absolutely amazing woodworking skills... i cant wait to see the end results!

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

Thank you very much guys. I finally have another update and it should be a big one.

I've been working quite a bit on this project recently and its finnally coming along quite nicely. I've been doing mostly aluminum but also some plexi/paper too and lots of designing, so here goes:

As usual, i have a new workspace... in my bedroom:

I have to give a special thanks to Dutchcedar for helping me out with the aluminum. He gave me some much needed advice on which tap to use and what to do. He also showed me the way of Mcmaster-Carr. Here is some stuff i got from them:

That tap cost me 15 bucks but Dutchcedar compared it to a Fine Dozuki saw so i had to get it. Here it is at work:

I assume most of you know how to drill holes so i didn't get too many pictures of the drilling, just pictures of what the parts look like after they're done.

First was attaching two 3/8inch by 1/2in bars to the main side panel:

Test fitting the middle floor panel:

Next step was to attach the front and back panels:

Oh, btw, all of the screws are 8-32 flat head socket screws and they look like this when countersunk:

The back:

With both panels:

Does the wood fit over the alu still? Yes it does :rock:

Then came more supports for the middle floor panel. This also helps support the bottom panel:

With them both installed and countersunk:

Then the top:

This is what i'm working on now:

My tripple core radiator and 70 bucks worth of fans come tomorrow so i can get the shroud started then.

I also did some plexi/paper stuff with the top panel:

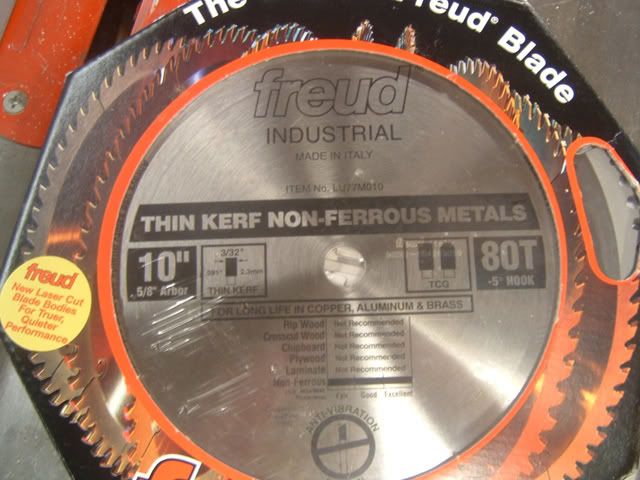

First i cut out the plexi... It fits, woo.

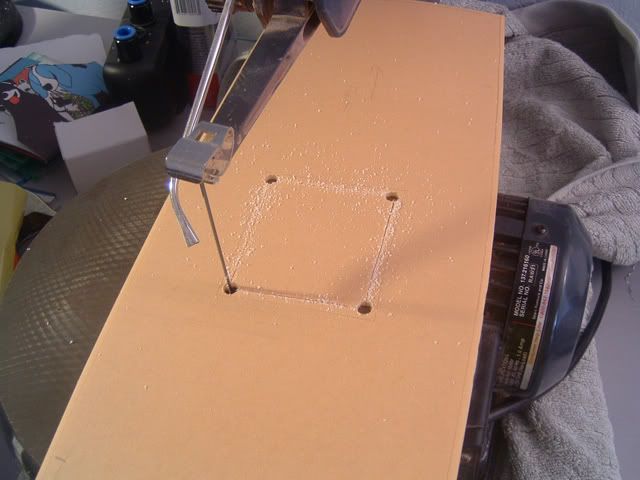

This is the same plexi that is a joy to work with that i got from delviesplastics. I'm not sponsored by them, i'm just really happy i don't have to work with crap plastic that melts.

then i needed a hole for a top exhaust fan:

After sanding:

I still can't decide weather i'm using a 120mm or 92mm fan here. the 92mm is about the size of the whole but the 120mm is huge. this is with a 120mm fan:

And with paper:

I need to glue the paper on in order to fit properly but i still have more work to do on the top before i can do that but here is a sneak peak of what it will look like.

Thats it for now. I'm spec-ing out my hardware though and for my psu, i'm probly going for a Silverstone strider 750w, any thoughts on this?

Before i left, i got a few goodies:

I got more fans than actually, they're just not in the picture.

When i went to put everything together though, that darn fans didn't fit since apparently they're a little bigger than normal fans. No worries though, i bought that aluminum blade a while back and i intend to utilize it.

The fans getting ready for surgery:

It cuts pretty nice for 25mm aluminum:

They fit!:

I already think it needs to be more curved. The curves around the white part will have a plexi ring lit with white leds for the top and bottom panels. The middle panel will be lit with a white ccfl. Everything will be black aluminum with the motherboard try being koa veneer. Enjoy.

Thanks a lot in advance guys. I'm working on the front still and i'm thinking of an anodized black brushed finished for all the alu including the front but the front also needs an extra something to break up the blackness. Let me know what you guys think of all of this.

I've been working quite a bit on this project recently and its finnally coming along quite nicely. I've been doing mostly aluminum but also some plexi/paper too and lots of designing, so here goes:

As usual, i have a new workspace... in my bedroom:

I have to give a special thanks to Dutchcedar for helping me out with the aluminum. He gave me some much needed advice on which tap to use and what to do. He also showed me the way of Mcmaster-Carr. Here is some stuff i got from them:

That tap cost me 15 bucks but Dutchcedar compared it to a Fine Dozuki saw so i had to get it. Here it is at work:

I assume most of you know how to drill holes so i didn't get too many pictures of the drilling, just pictures of what the parts look like after they're done.

First was attaching two 3/8inch by 1/2in bars to the main side panel:

Test fitting the middle floor panel:

Next step was to attach the front and back panels:

Oh, btw, all of the screws are 8-32 flat head socket screws and they look like this when countersunk:

The back:

With both panels:

Does the wood fit over the alu still? Yes it does :rock:

Then came more supports for the middle floor panel. This also helps support the bottom panel:

With them both installed and countersunk:

Then the top:

This is what i'm working on now:

My tripple core radiator and 70 bucks worth of fans come tomorrow so i can get the shroud started then.

I also did some plexi/paper stuff with the top panel:

First i cut out the plexi... It fits, woo.

This is the same plexi that is a joy to work with that i got from delviesplastics. I'm not sponsored by them, i'm just really happy i don't have to work with crap plastic that melts.

then i needed a hole for a top exhaust fan:

After sanding:

I still can't decide weather i'm using a 120mm or 92mm fan here. the 92mm is about the size of the whole but the 120mm is huge. this is with a 120mm fan:

And with paper:

I need to glue the paper on in order to fit properly but i still have more work to do on the top before i can do that but here is a sneak peak of what it will look like.

Thats it for now. I'm spec-ing out my hardware though and for my psu, i'm probly going for a Silverstone strider 750w, any thoughts on this?

Before i left, i got a few goodies:

I got more fans than actually, they're just not in the picture.

When i went to put everything together though, that darn fans didn't fit since apparently they're a little bigger than normal fans. No worries though, i bought that aluminum blade a while back and i intend to utilize it.

The fans getting ready for surgery:

It cuts pretty nice for 25mm aluminum:

They fit!:

I already think it needs to be more curved. The curves around the white part will have a plexi ring lit with white leds for the top and bottom panels. The middle panel will be lit with a white ccfl. Everything will be black aluminum with the motherboard try being koa veneer. Enjoy.

Thanks a lot in advance guys. I'm working on the front still and i'm thinking of an anodized black brushed finished for all the alu including the front but the front also needs an extra something to break up the blackness. Let me know what you guys think of all of this.

t_ski

Supreme [H]ardness

- Joined

- Jun 13, 2006

- Messages

- 7,506

Once again, it's just incredible. The only question I can ask at this point is, where are you planned on putting the optical drive? Or is it not part of the plan?

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

t_ski said:Once again, it's just incredible. The only question I can ask at this point is, where are you planned on putting the optical drive? Or is it not part of the plan?

Thank you very much. For the optical drive, i'm using a slim slot loader that'll go close to the top of the front plate like normal once i figure out how to mount it. I'm using a slot loader so all i have to do is mill a little line. It should be sweet.

digital_exhaust

[H]ard|DCer of the Month - May 2008

- Joined

- Aug 14, 2006

- Messages

- 6,903

Absolutely unbelievable.

I don't know what else to say.

I don't know what else to say.

Jarod888

2[H]4U

- Joined

- Dec 19, 2005

- Messages

- 2,943

What a beautiful case! I have one of those saws, the Dozuki, I used it this summer; I tried my hand at making dovetails, but I ran out of patience and used kregg screws. If I had more time I think I would like to make a wooden case, but I just don't have the time. Anyways, what great looking case!!

jackofalltrades

2[H]4U

- Joined

- Feb 7, 2006

- Messages

- 3,740

true craftsman!

D

Deleted member 50702

Guest

Truely amazing work so far, it's not often I'm taken to awe by a case.

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

Thank you very much every one for your comments. They defiantely help in keeping this project moving and I appreciate them very much. As far as work goes, i'm home for winter break and this case is priority #1 until it is finished. I should have an update shortly.

Who is Nick Falzone?

I am

Who is Nick Falzone?

I am

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

fenton06 said:oh...how in the HELL do you pronounce the name of your project, and where did you get the name?

The name is pronounced "you-go" and how i got it was first I figured out what I wanted it to mean. I wanted something that stood for the fusion of two things, in this case that meant technology and tradition. My roommate is Japanese so I asked him what the word for "fusion of two things" in Japanese and Yuugou is what he told me.

tylerdustin2008

[H]ard|Gawd

- Joined

- May 6, 2006

- Messages

- 1,834

DAMN it is looking GREAT. I need a couple of tools so i can so some more extensive modding.

DarkenReaper57

2[H]4U

- Joined

- Oct 2, 2003

- Messages

- 2,173

You, sir, have excellent wood-working skills. I only wish I could build something that nice. I can't wait to see it done!

A very inspiring project, your Japanese details in this design are really superb. I live in Japan and see beautiful work on a daily basis, but this is really something new. Whatever you do... don't hurry to finish! No matter how much we plead. Too much effort invested so far to rush it now. I do hope that this box will be relatively quiet to match it's tranquil appearance, but all those fans look noisy. Have you tried them out yet?

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

Thank you very much guys. The fans can be really noisy. I used 4 of them (1 120mm and 3 92mm) on my last case, Sangaku and they can be loud but when you turn them down like I will be doing, they aren't loud at all. The thing I like about these fans is even when they are loud, its not a high pitched whizz but a nice lower pitched sound. Either way, the case will definitely be nice and quiet like it should be.

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

I worked like crazy this weekend on random stuff, some of which was computer case stuff. I made a list of things i had to get done on the case before i go home for winter break and it turned out to be huge so i decided to get one of the most dreaded things out of the way... the back panel.

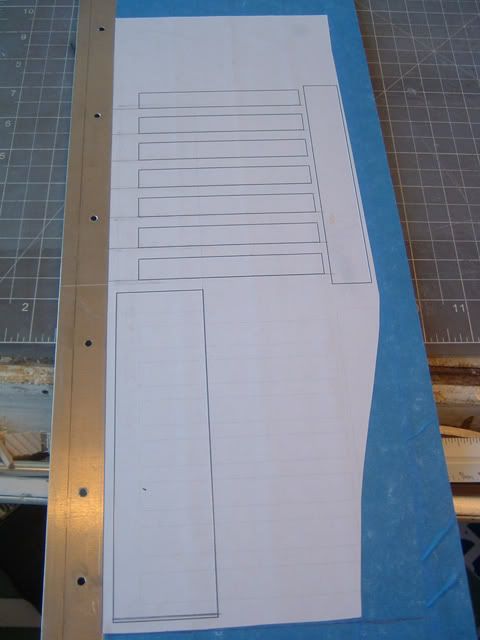

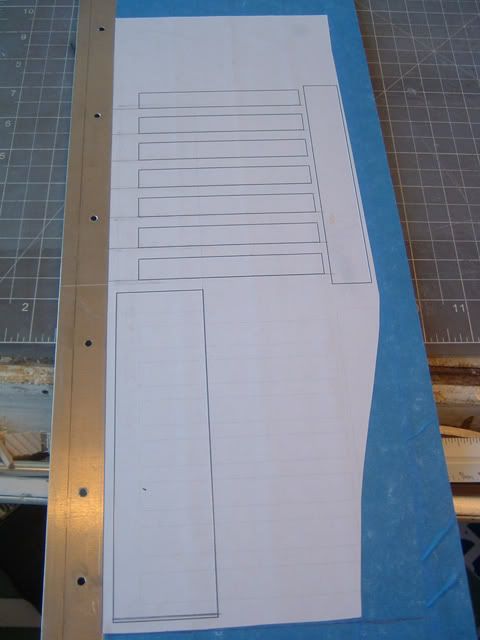

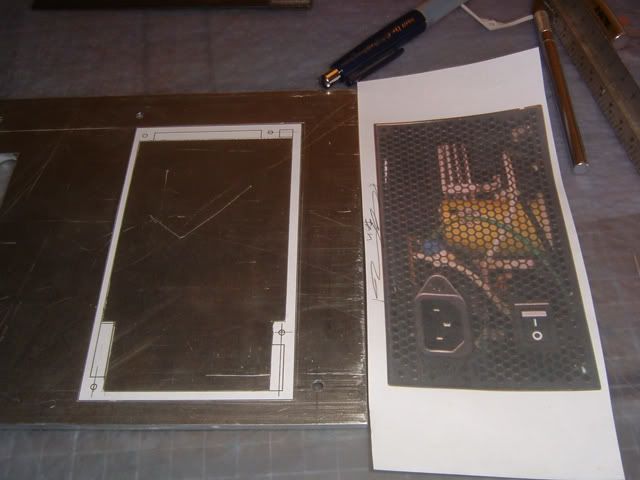

I took a while to draw out the design in Adobe Illustrator. I used an old mobo tray as a template and once i had it perfect, I printed it out full scale and temporarily glued it to the alu:

I traced the lines with an exacto knife and ended up with this:

And then it was time to mill... for about 3 hours...

I'm using a half inch bit for this (pretty much the only sharp bit in the shop).

I had a helper for this part so I wasn't taking the pictures. The person in these is me.

Starting to cut:

Screw safety glasses:

Gotta have lube though:

My helper Carl:

It got easier the more slots we did:

Almost done...er not really:

Important compressed air:

One hole left:

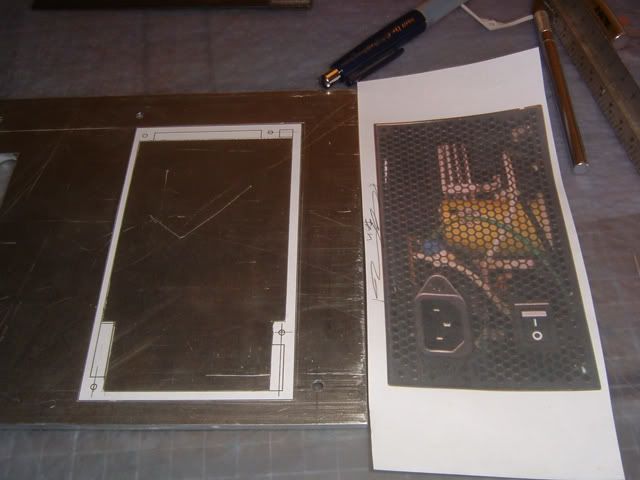

And wala. Its really starting to look like something now and the good news is, the more Aluminum i mill out of this thing, the lighter its going to get

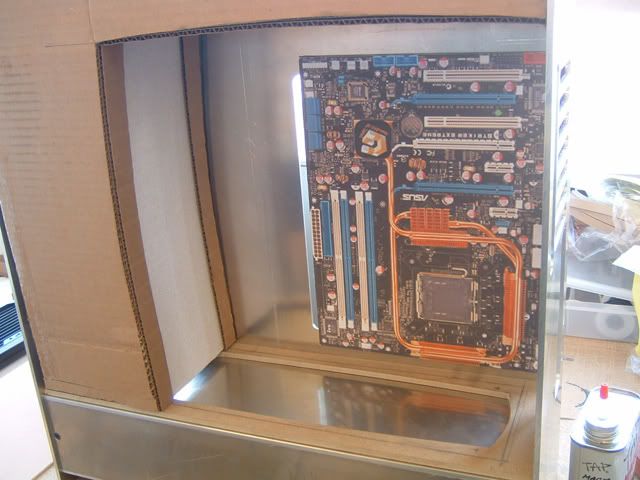

And with my cardboard Asus striker extreme motherboard installed:

The cuts turned out pretty clean but they're going to need a fair bit of sanding still. On the bright side, i still have tons more milling to do. Tomorrow, i plan on milling the slot for the motherboard cables and maybe the hole for the pump in the main side panel. I also have to make the fan holes and start cutting the curves in the aluminum for the interior panels. Until then, stay tuned.

Nick

I took a while to draw out the design in Adobe Illustrator. I used an old mobo tray as a template and once i had it perfect, I printed it out full scale and temporarily glued it to the alu:

I traced the lines with an exacto knife and ended up with this:

And then it was time to mill... for about 3 hours...

I'm using a half inch bit for this (pretty much the only sharp bit in the shop).

I had a helper for this part so I wasn't taking the pictures. The person in these is me.

Starting to cut:

Screw safety glasses:

Gotta have lube though:

My helper Carl:

It got easier the more slots we did:

Almost done...er not really:

Important compressed air:

One hole left:

And wala. Its really starting to look like something now and the good news is, the more Aluminum i mill out of this thing, the lighter its going to get

And with my cardboard Asus striker extreme motherboard installed:

The cuts turned out pretty clean but they're going to need a fair bit of sanding still. On the bright side, i still have tons more milling to do. Tomorrow, i plan on milling the slot for the motherboard cables and maybe the hole for the pump in the main side panel. I also have to make the fan holes and start cutting the curves in the aluminum for the interior panels. Until then, stay tuned.

Nick

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

I've been working like crazy on this and I have done enough work for about 3 updates but I want to get everything organized so for this update, I have some more milling that I did.

First, i needed a big hole for the pump to go through. This was so the fans can connect to the back of the pump and because the pump didn't fit

Next is a hole for the mobo wires. This is so there are no wires in the front to block all the prettiness:

And then a hole for the psu.

Laying it out:

And its done:

Taking a break with the update, I thought you guys might like to see my latest architecture project. For this, we had to create a huge white model of a house. After waiting for most of the quarter to start, this thing came out:

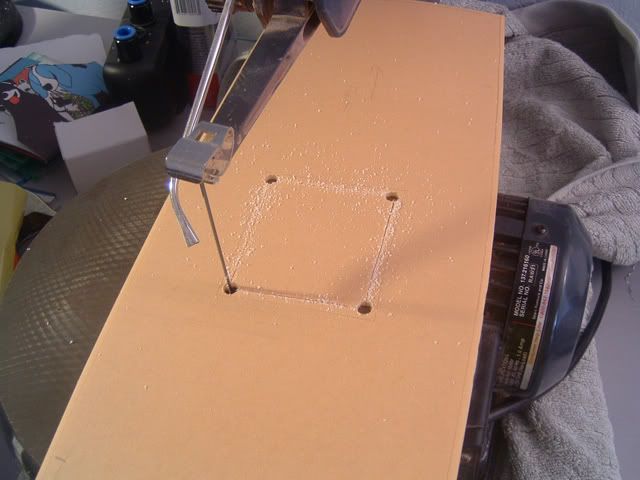

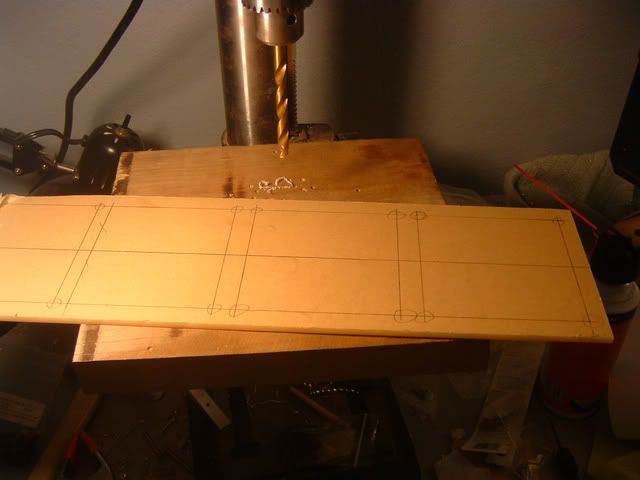

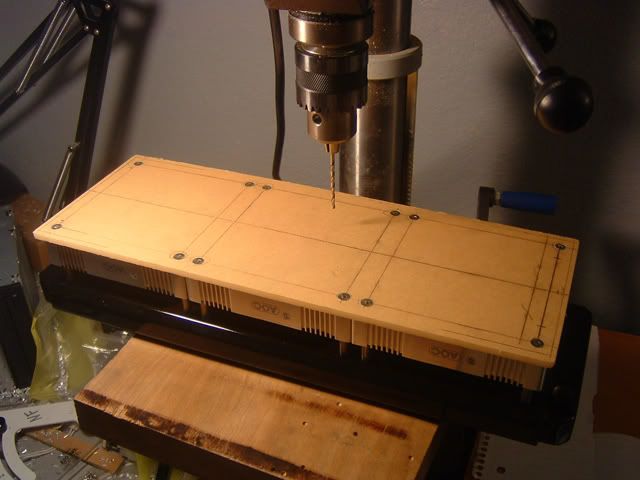

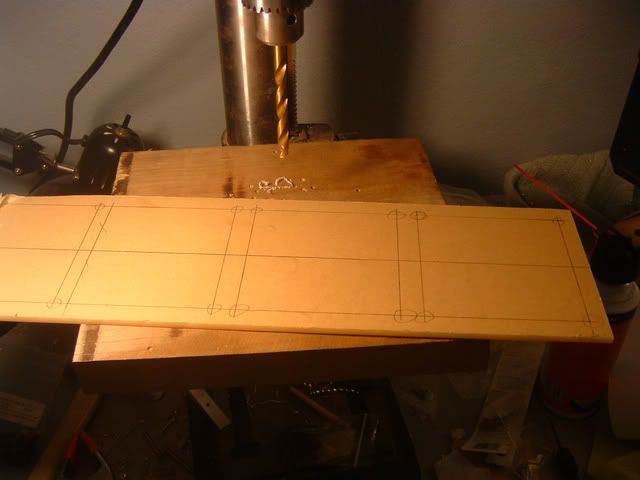

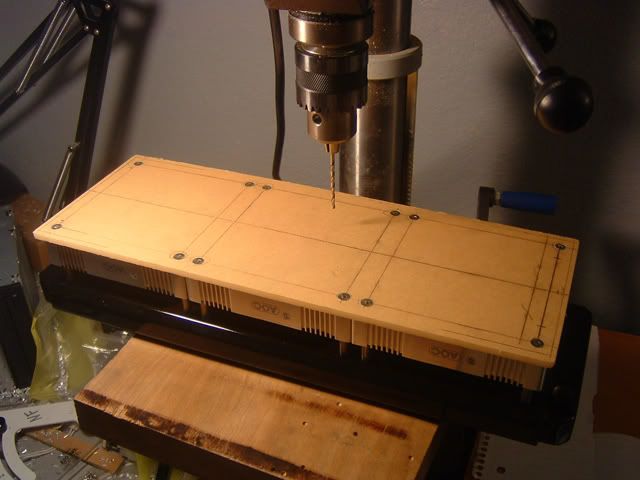

Next is the big hole in the bottom for the fans. I had to make a template out of wood first:

First i drilled holes to get the jig saw in:

Then I used the jigsaw to cut it out roughly... very roughly:

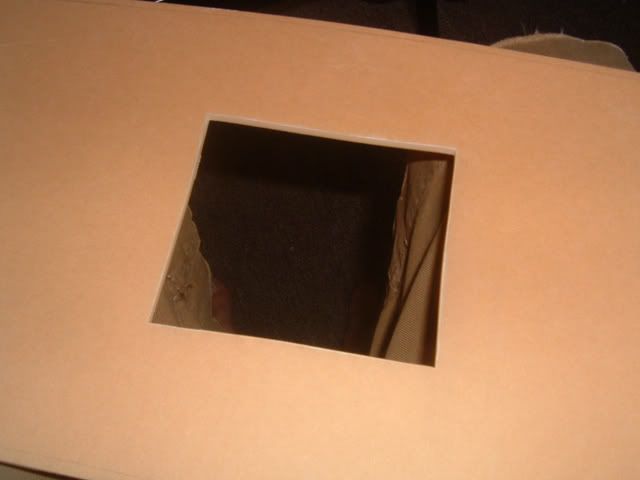

It was then time to clean it up using the router table and the template:

It does a surprisingly nice job:

I did a lot of sanding and such just to see what it looks like and it looks pretty pretty. I have a lot more work done which I will show you guys soon:

Stay tuned

First, i needed a big hole for the pump to go through. This was so the fans can connect to the back of the pump and because the pump didn't fit

Next is a hole for the mobo wires. This is so there are no wires in the front to block all the prettiness:

And then a hole for the psu.

Laying it out:

And its done:

Taking a break with the update, I thought you guys might like to see my latest architecture project. For this, we had to create a huge white model of a house. After waiting for most of the quarter to start, this thing came out:

Next is the big hole in the bottom for the fans. I had to make a template out of wood first:

First i drilled holes to get the jig saw in:

Then I used the jigsaw to cut it out roughly... very roughly:

It was then time to clean it up using the router table and the template:

It does a surprisingly nice job:

I did a lot of sanding and such just to see what it looks like and it looks pretty pretty. I have a lot more work done which I will show you guys soon:

Stay tuned

t_ski

Supreme [H]ardness

- Joined

- Jun 13, 2006

- Messages

- 7,506

Looking great, but you've forced me to climb on my soapbox...

Please, it is extremely important to wear the necessary safety equipment at all times. You don't want to mess with your eyesight. Especially since you are working with metal, blowing shavings around with compressed air, it can be very easy to get something in your eyes. I've worked with metal for several years and I can tell you first hand it is no fun to have a doctor drilling out your lens to remove a piece of metal lodged in there.

All tools, but especially power tools, can be extremely dangerous. You must respect their power at all times, and use extreme caution. I don't want other people to suffer the same fate as me and have a part of your body lobbed off because they were not doing eveything they could to avoid an accident.

I can see you are young, and sometimes youth blinds you, thinking that your are invincible. Your not. No one is. After seeing all the great work you can do on this case and your last one, I hope you can continue to thrill us with your work for many years to come. Please, were your PPE and work safe.

This concludes the PSA portion of my post. Thanks for listening.

Please, it is extremely important to wear the necessary safety equipment at all times. You don't want to mess with your eyesight. Especially since you are working with metal, blowing shavings around with compressed air, it can be very easy to get something in your eyes. I've worked with metal for several years and I can tell you first hand it is no fun to have a doctor drilling out your lens to remove a piece of metal lodged in there.

All tools, but especially power tools, can be extremely dangerous. You must respect their power at all times, and use extreme caution. I don't want other people to suffer the same fate as me and have a part of your body lobbed off because they were not doing eveything they could to avoid an accident.

I can see you are young, and sometimes youth blinds you, thinking that your are invincible. Your not. No one is. After seeing all the great work you can do on this case and your last one, I hope you can continue to thrill us with your work for many years to come. Please, were your PPE and work safe.

This concludes the PSA portion of my post. Thanks for listening.

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

You don't have to worry, I am now wearing safety glasses on all work of this sort. I also know i'm not invincible. Awhile ago when i was running cross country, i got a stress fracture in my ankle that pretty much killed my invincibility hopes, but a reminder is always helpful. Thanks for looking out for me.

digital_exhaust

[H]ard|DCer of the Month - May 2008

- Joined

- Aug 14, 2006

- Messages

- 6,903

greensabbath said:You don't have to worry, I am now wearing safety glasses

Good.

I lost sight in my left eye when I was 23 years old due to stupidity.

Just a heads up from someone who knows.... not wearing safety glasses is fucking retarted...

Your work is amazing. With each update I become more and more awe-stricken by your skills and imagination. This is just breathtaking.

I cannot wait for more.

t_ski

Supreme [H]ardness

- Joined

- Jun 13, 2006

- Messages

- 7,506

Its looking sexxy!

your "house" looks pretty sweet too!

one little heads up, can you fit your monitor cable and other thinks into the slots? (because the rear case thickness is about .25" from the looks of it)

I know some connections on the back of mobo's or PCI cards some times overhang were the slot is in the case, so just sometihng to keep an eye on early

either way it would suck if it didn't work, but its better to catch now rather than when its fully assembled

your "house" looks pretty sweet too!

one little heads up, can you fit your monitor cable and other thinks into the slots? (because the rear case thickness is about .25" from the looks of it)

I know some connections on the back of mobo's or PCI cards some times overhang were the slot is in the case, so just sometihng to keep an eye on early

either way it would suck if it didn't work, but its better to catch now rather than when its fully assembled

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

dementer said:Its looking sexxy!

your "house" looks pretty sweet too!

one little heads up, can you fit your monitor cable and other thinks into the slots? (because the rear case thickness is about .25" from the looks of it)

I know some connections on the back of mobo's or PCI cards some times overhang were the slot is in the case, so just sometihng to keep an eye on early

either way it would suck if it didn't work, but its better to catch now rather than when its fully assembled

Thank you. The connectors and cables do fit. The back panel on this one is 3/16 but on my last case it was 1/4 and they fit on that. Its really close but it works. I might take a bigger mill bit and mill the slots a little more of the way down just to make sure though.

greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

I've been working a lot with that big bottom hole and the radiator and getting that whole thing mounted. To do this, i figured i'd cut a bunch of holes in some plexi to attach the rad to the fans, then screw from the aluminum plate into the fans. here goes:

Gonna drill:

All drilled up and attached:

Next was attaching this to the aluminum. I love these fans:

And a side shot: (that gap between the rad and fans will be covered)

Its coming along but it still need a bit hole to allow air in:

This is when i noticed something. See this?:

Thats just ugly and in order to make this work, i'd have to leave way too much acrylic so the only solution was to make a new top plate with only 4 holes to hold the fans on but this way i could cut the plexi flush.

Like this:

Which leaves this:

I've also been working on the rest of the alu for the main shroud in the interior. The white pieces are the alu (the horizontal strips are just for temporary support).

One last shot with that side rad cover on:

Over break I hope to get all of the aluminum done but that will most likely not happen. I already have most of the template done though so we'll see. Thanks again guys and enjoy.

Gonna drill:

All drilled up and attached:

Next was attaching this to the aluminum. I love these fans:

And a side shot: (that gap between the rad and fans will be covered)

Its coming along but it still need a bit hole to allow air in:

This is when i noticed something. See this?:

Thats just ugly and in order to make this work, i'd have to leave way too much acrylic so the only solution was to make a new top plate with only 4 holes to hold the fans on but this way i could cut the plexi flush.

Like this:

Which leaves this:

I've also been working on the rest of the alu for the main shroud in the interior. The white pieces are the alu (the horizontal strips are just for temporary support).

One last shot with that side rad cover on:

Over break I hope to get all of the aluminum done but that will most likely not happen. I already have most of the template done though so we'll see. Thanks again guys and enjoy.

You are doing an excellent job.

Since you seem to be doing a lot of it throught he school, do they finance the supplies? The amount of aluminum you are using racks up quite fast, especially at that tickness. Does this double as a project in class?

Also, whats the concept behind the archetectual buildings that you had to do? Did everyone deal with the same platform to do a design on? Were you guys instructed to show more art and conceptulization rather than function?

Since you seem to be doing a lot of it throught he school, do they finance the supplies? The amount of aluminum you are using racks up quite fast, especially at that tickness. Does this double as a project in class?

Also, whats the concept behind the archetectual buildings that you had to do? Did everyone deal with the same platform to do a design on? Were you guys instructed to show more art and conceptulization rather than function?

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)