ikellensbro

[H]ard|Gawd

- Joined

- Feb 14, 2004

- Messages

- 1,410

QFT x10el rolio said:

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

QFT x10el rolio said:

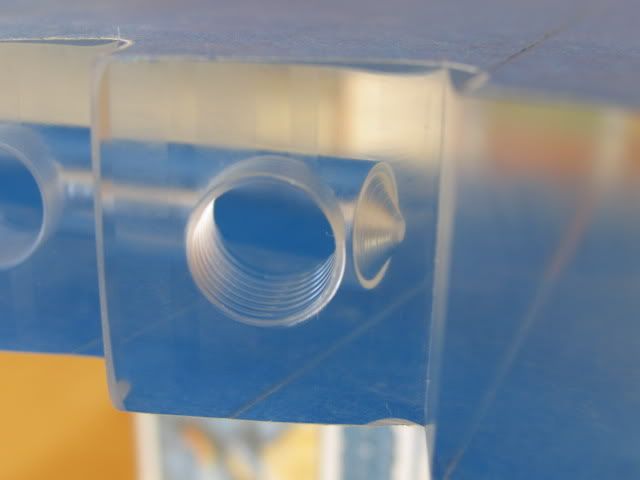

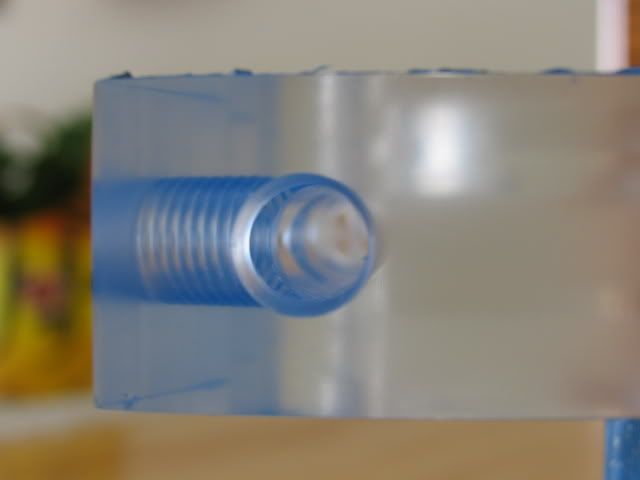

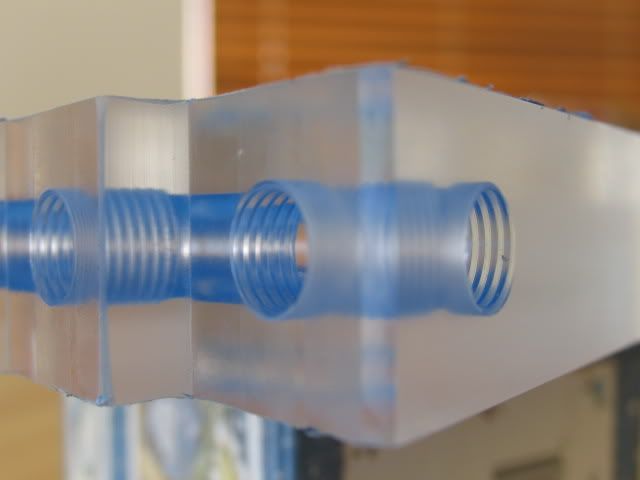

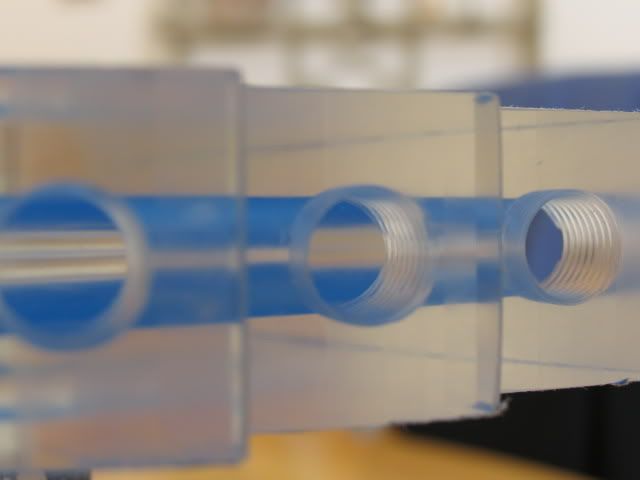

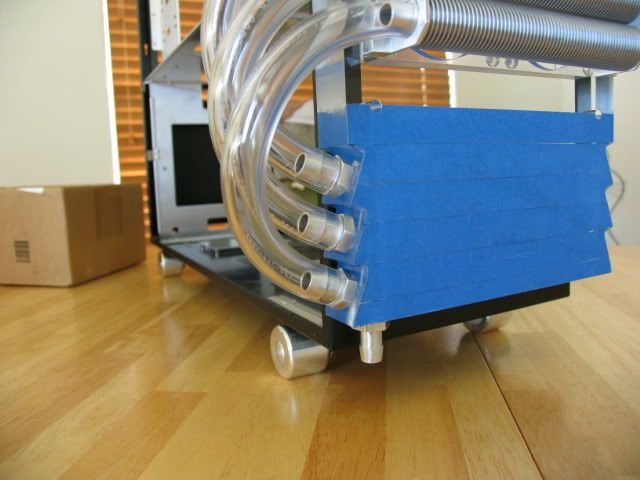

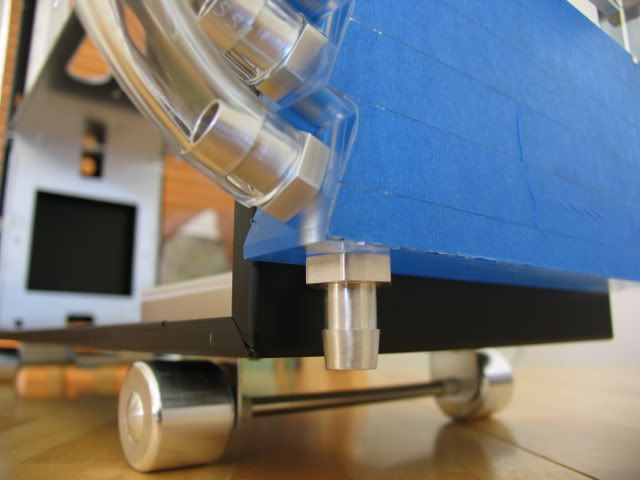

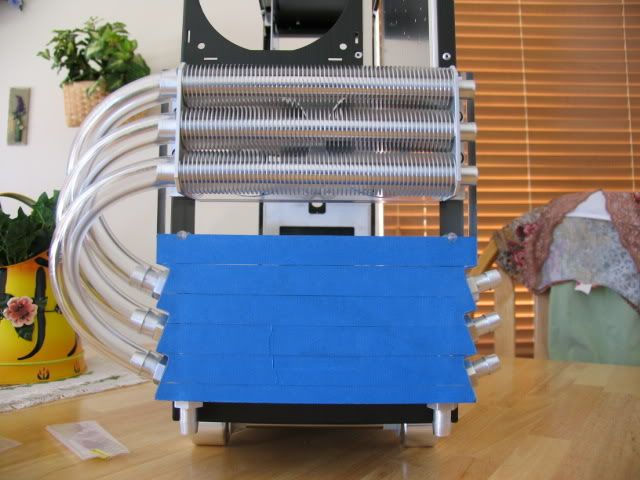

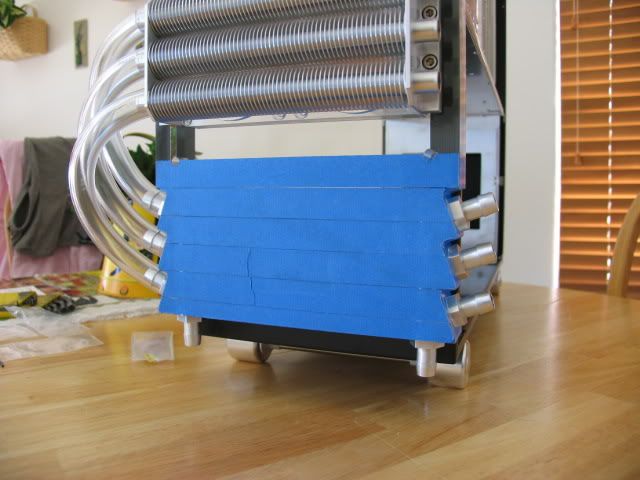

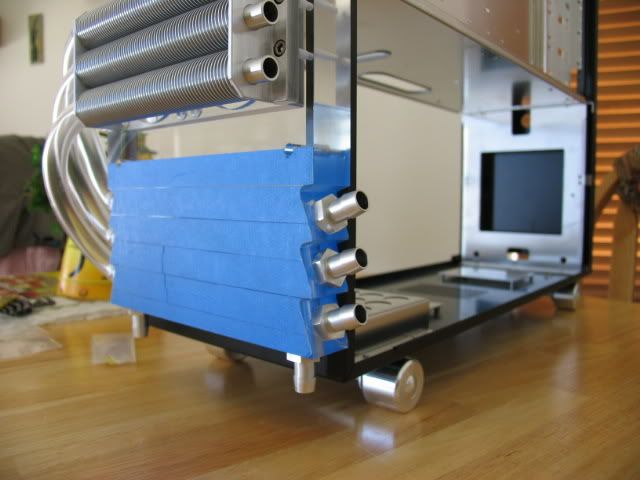

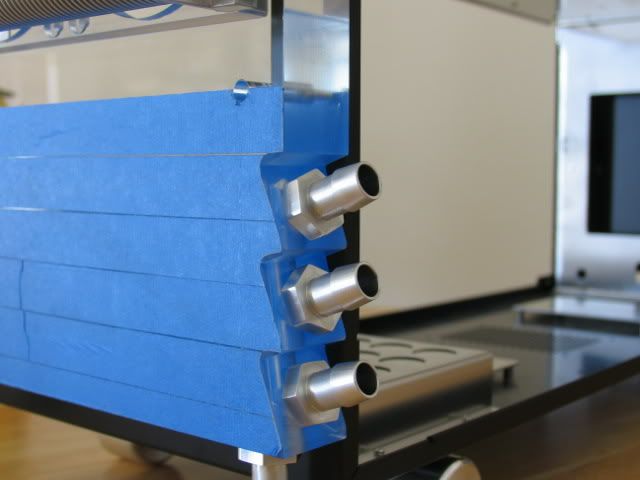

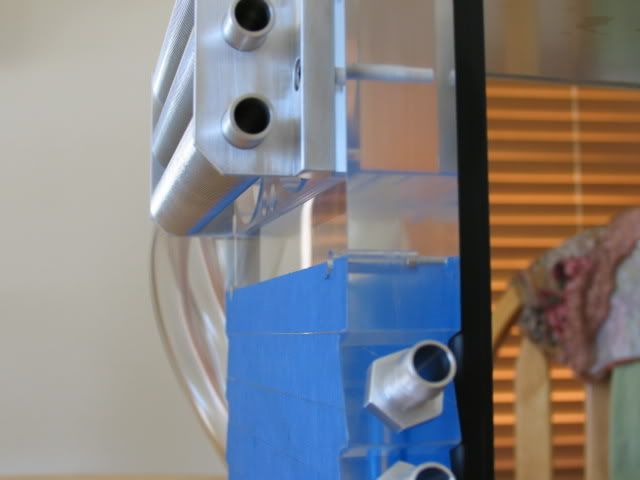

Dissipate heat transferred from the water (of the water cooling system) running through them. It's a DIY radiator...very [H]ardTechnoob said:forgive my noobitude, but what do those coils do?

QFTx10.5!ikellensbro said:QFT x10el rolio said:

jmroberts70 said:If there was anything on the internet I liked looking at as much as porn, it would have to be THIS THREAD!!

That is exactly what I said to myself. I am amazed at how you can do all of that on your own.0mega said:hoe. lee. shit.

Anavel0 said:Nice mod, I love stopping by and seeing how it changes.

But uh, just one question. What about galvanic corrosion due to the two different types of metal you are using in your loop, the copper and aluminum. In the boating world to help stop galvanic corrosion we add a small "sacraficial metal' to the outboard part of the engine. This is normally zinc or aluminum. And iirc your fin radiator is aluminum and the pipe going through it is copper.This might be bad.

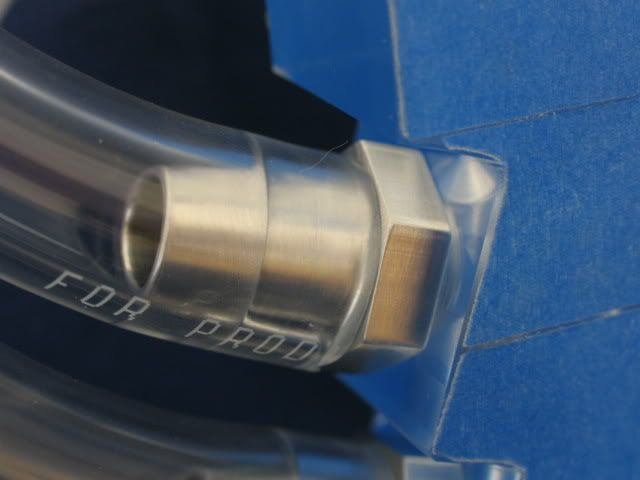

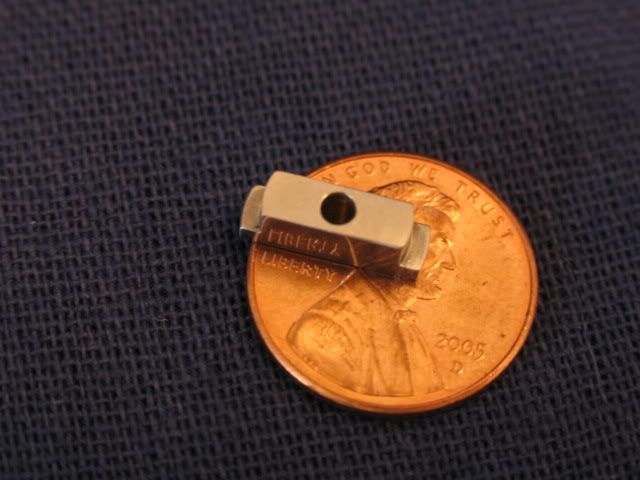

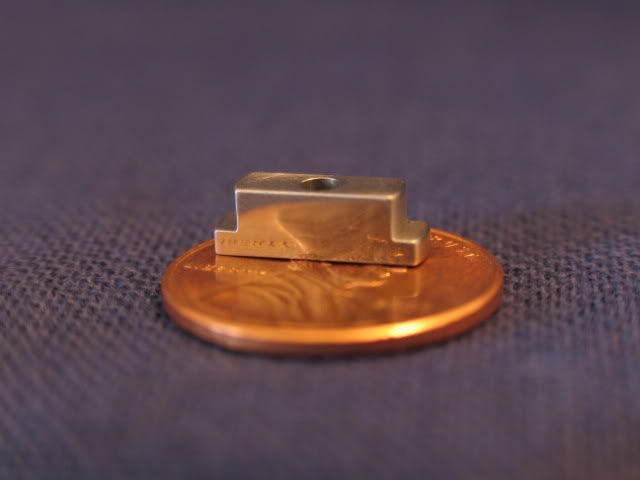

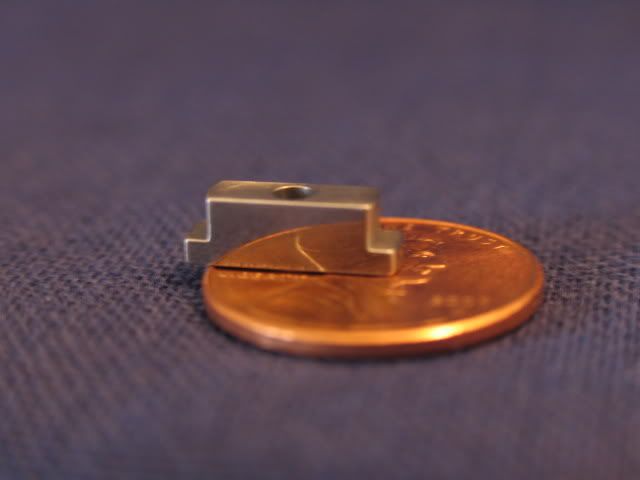

Stevennoland said:That is all I have done. I have yet to determine what color the barbs and finned tubes (and mounts) will be anodized. It's either going to be rad or black or some combo of the two.

dasilva333 said:anodized in a mix of the two would be nice =D helluva job you've done so far keep it up!

question about the whole setup can you kinda guide us through the bottom loop? are those circular fins going to be on a seperate loop or is it all going to be going through the same pump? multiple pumps maybe? with all that water flowing through are you even going to need a res?

brasherman said:You know, I thought that the rear finned tubes looked familiar, and I think I know why. They look exactly like the water to air intercooler tubes in the new Eaton supercharged Cadillac motors. You know, the CTS-V, STS-V? 460 HP out of them is not shabby at all. Biggest eye opener was learning there's more there with refinement.

Am I close? If so, do I win a custom machined prize?

Legion© said:If i understand this correctly you're planning to anodize the aluminium parts? If the anodizing is also done on the inside of the finned tubes it will pretty much eliminate any galvanic corrosion (The same reason why Zalman anodize their water cooling blocks)?

I would've continued Metalwork after Gr.9 if I wasn't afraid of the welding tools and the dumb fucks in my class who wielded themBorgschulze said:Machine shop is my favourite class, and going into grade 12 this year, we get to build what we want to, best believe I'm finally going to make a case for (cf)Eclipse's Newark he killed

I just wish I was as good as you are, you do some amazing work only an experienced machinist could ever dream of.

Also, I have tapped copper before, and it is annoying, aluminum however cuts like butter.

tylerdustin2008 said:You are using a cnc mill right. And if so its the one at work, if you own one you are rich!!! But anyway nice work, there is no way in hell i could do that work without a mill and some $$$. If i had those items i would build the same type of setup you have. And what has this build cost you so far?

n00btard said:I would've continued Metalwork after Gr.9 if I wasn't afraid of the welding tools and the dumb fucks in my class who wielded them

Stevennoland said:It's funny how fear can do that. It either makes you weaker or stronger (no middle ground).

Steven