BellaCroix said:I want to know where you found AC compatible fill ports from... I didn't notice any reducers (might be the 6-pack of Guinness I just finished) but I've never seen fillports with hose sized small enough for the Germans.

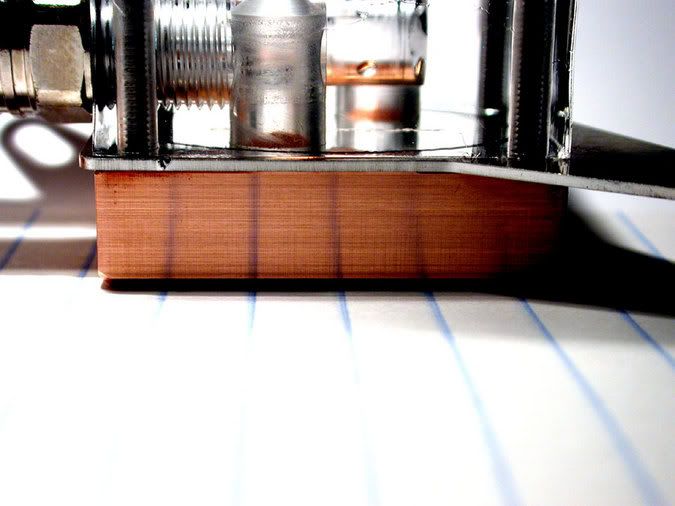

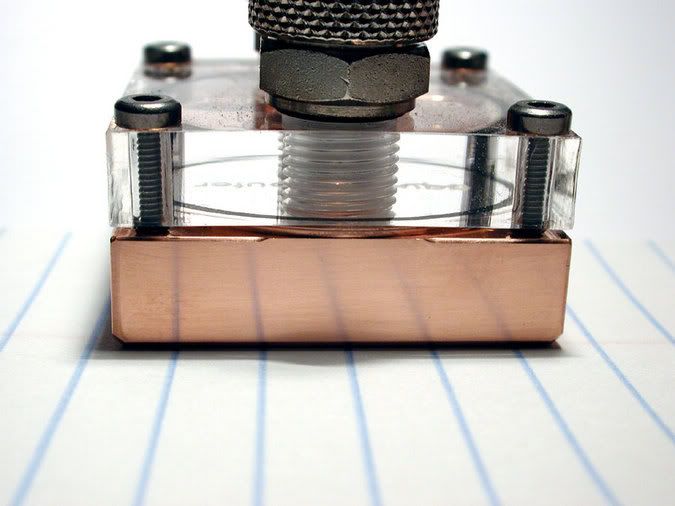

I bought the standard DD Fillport with the 3/8" barb from Sharka and got one of the 3/8" barb x 1/8 BSPP adapters from them as well. Screwed the adapter into the back of the Aquatube and attached the 3/8" ID tube to both and presto-chango I had a Fillport ready to roll on a horizontally mounted Aquatube.

Check back here in a few more weeks when the new AC stuff shows up at Sharka and you will see an even better setup. How about a FillPort that will bleed and fill all three loops.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)